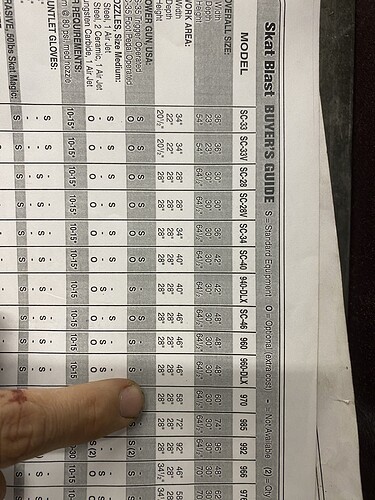

Hi Folks: I think I am about to buy a sandblast cabinet. I always thought I would make one, but given time constraints, I will likely go off the shelf. I will probably buy one of the Skat Blast cabinets from TP tools - not too far away from me in Ohio. I an effort to avoid buyer’s remorse, looking for input on what size cabinet is ideal or at least considered minimum for basic bike frames (not looking to accommodate tandems, cargo, etc.). Thanks for any input. Daniel

I should have included the URL for TP tools in case anyone is interested:

Thanks, Daniel

I’ll grab some dimensions next time I’m at my blast/paint studio, but I’d suggest “bigger than you’d think” ![]() I was just stripping an XL frame and even though it fit fine, it was very awkward to blast the front of the head tube and back of the dropouts.

I was just stripping an XL frame and even though it fit fine, it was very awkward to blast the front of the head tube and back of the dropouts.

Many thanks! This is what I suspect. I would rather buy a little over sized, forget what I paid and remember that it works well every time I use it.

Great post! I’m also considering getting my own cabinet along with an air compressor. Additionally, I’m curious if anyone has any suggestions regarding the ideal blasting abrasive for titanium. Could someone provide me with some tips?

Nice follow-up. I was also wondering about favorite blast media - for steel in my case. Would love to hear what folks use.

I bought a used cabinet from a local body shop guy some years back, it has 2 doos on the side and the top lifts up as well which is pretty essential for getting a frame into it. The cabinet is 4’x2’x2’ inside which is enough for me to get most frames in without too much issue. Having one that had a little more head clearance would be great for very tall frames and to help rotate the frame without having to pull it out and flip it but I think that generally means all the dimensions increase which ends up taking a lot of floor space. As far as media (I build with steel) I use crushed glass. It’s abrasive enough to take the excess flashing off silver/bronze brazed joints but isn’t really cutting into the steel. I have used crushed walnut shells for unpainted stainless frames which leaves a nice finish.

This is the one I use! It’s great for most frames but like I said gets kinda clumsy with XL and up. I’m curious to see how my (very long) hardtail fares next week. 58x28x28” work area.

And this is the blast media that’s currently in there. It’s fine for frame prep but not the best for stripping paint.

I’ll second @liberationfab on the “bigger than you think” sentiment. I bought a cabinet that I thought would be big enough but I ended up cutting the back off and building a large plywood extension (couldn’t have gotten something this large into my shop in one piece anyways.) Used caulk on (and in) all seams then covered that with aluminum furnace tape as an extra coverage to avoid leakage. I bought the original cabinet from a farmer who made it himself so it doesn’t seem to be of standard dimensions, I think he said they made it from an old seed hopper.

The original cabinet was 100 cm wide, 76cm tall (not counting the collection cone) and 61cm deep. The door opens one side of the original cabinet almost completely. That fit small to medium frames but I had to take them out to turn them around. I wanted to be able to move and rotate the frame without removing it so I added an extension, which didn’t change the height or width, but means the cabinet is now 120cm deep. The additional box has a sloping floor so blasting media works its way back to the main collection cone. The whole thing looks kinda nuts but it works and doesn’t leak (much) and was a hell of a lot cheaper than the large media blast cabinets that were that large off the shelf. If I was outfitting a large space that had more than a residential size door a bigger cabinet would be really slick, but this gets the job done.

Oh, I also removed the floor grate to get some extra room, I think I learned that seeing a picture of Brian Chapman using his cabinet and i could see he had gained more vertical space by getting rid of that.

For blast media I’ve used 80 grit crushed glass and it is very gentle, sometimes a little slow for my taste. It was not great for paint removal but it worked okay for prepping bare frames for paint. I’m not sure if my experience has been shaped by a pretty worn diy siphon. New tips but cludgy rest of setup.

I recently got some ALC black oxide stuff and it was super fast for removing paint, I’d be nervous using it around silver brazed lugs for fear of creating undercuts at the lug line. But it took paint off like a champ.

I just got a bag of a different brand and style of the crushed glass and we’ll see if my experience improves with that stuff, I’d personally rather stand at the cabinet a bit longer than be skirting disaster with the faster cutting stuff, especially with silver and lugs. Hopefully i can find a goldilocks zone.

I just remembered this today- This is a bit beyond cabinet size, but my toughest lesson in purchasing/setting up a blast cabinet was realizing my air compressor couldn’t keep up, so the cabinet was initially useless. Make sure you’ve got a compressor that has a large enough tank and then a powerful enough compressor/pump to keep up with the cabinet’s use of air. Some compressors are rated specifically for continuous use at certain CFMs, so those in particular wont get burnt out by the high air use of a cabinet as easily.