im designing a new front triangle, for a swingarm and linkage from an existing frame ( evil bikes delta link ) , and both the seat tube, and the downtube, in order to touch what they need to touch, and not touch what they need not to touch, need to wiggle.

the seat tube is constrained by the bb, the seat, a very long dropper post, a pivot mount, a seat stay “bridge” on the swingarm, and missing the shock (notably the piggyback on/just past bottom out)

the downtube needs to meet the bb and headtube, support a linkage mount midway, and not interfere with the shock

my current favoured option is to join two tubes together to form each tube.

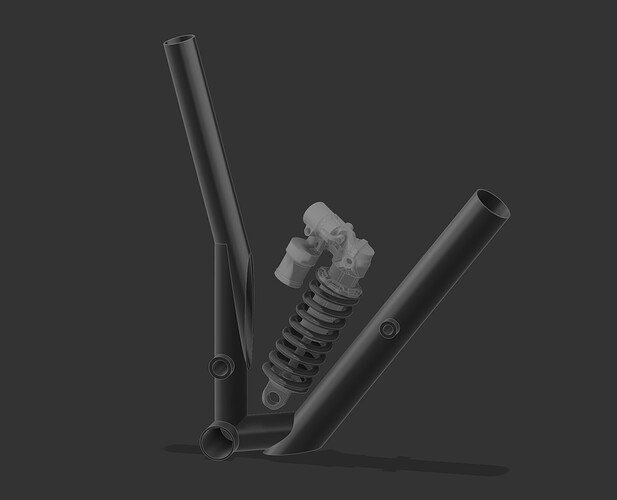

something like this.

id likely use a 44.45X0.9mm downtube, and a 34.9X1,6mm seat tube.

Im still pondering further support for the forward most pivot mount, I am considering fillet brazing this.

i’m feeling enough confidence In this arrangement to put it together, but though it was a good opportunity to put it to the floor for critique, because there’s obviously magnitudes more experience on this forum than I have alone.

1 Like

What is disctating the two angles of the seat tube componenets?

14.8 degrees.

current plan would be to weld this up with basically a solid heatsink in the upper tube, before fitting it to the bb, and finally machining the pivot mount hole.

I don’t have anything technical to add, just some food for thought.

These machined/cast BB clusters seem like a good solution to create pivot and shock mounting points while shifting the DT forward:

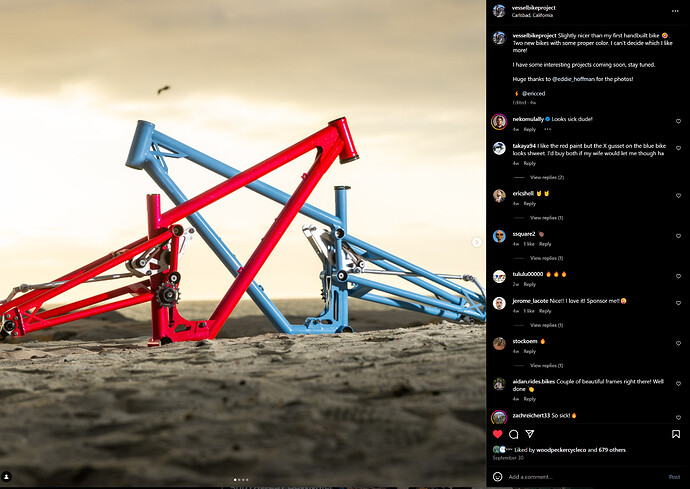

Jack at Vessel bike project has a similar form factor to your layout. The plates that reinforce the DT BB joint and serve at mounting locations look pretty optimized:

https://www.instagram.com/p/DAkQTX5Jh8W/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==

3 Likes

I used flat plate to tie all my critical points together and off set the downtube from the bb in order to it it all in and get my front shock mount where it needed to be.

Designed with a flat reference point that could sit on my jig.

Next one I’ll likely put in some little relief cuts to remove the long piece that connects the front shock mount to the bb cluster. After tacking the front shock mount in place trim it out. It was really nice to have all four holes pre-located in the single flat plate.

3 Likes

Thanks for sharing this. I’m planning a FS mountain bike and had been hoping to use laser cut plate in a similar was as you did. What thickness of plate did you use?

1 Like

thanks for the replies!

I think, given I also need a mount for that lower shock eye, some ‘side-plates’ that further tie all five “tubes” together, aswell as to the lower-eye mount, are going to be added in here, somewhere between what you’re doing Earle, and what Daniel posted of jack at vessel. the hardware spacing of 20mm sorta works quite nicely to tuck in this space so I don’t think they’ll need to be very complex.

the machined bb-with-pivot isn’t catching my eye as much; they are beautiful, and obviously very carefully made, but I feel like the hollow/flat corners next to that downtube butt join need to have been engineered with a cleverness beyond my capabilities, or they just wouldn’t last; the lack of faces parallel with the central plane of the bike really stands out to me as a bizarre choice.

I suppose I do use heavy tubes compared to those guys so likely it’s a horses for courses scenario; but if I was trying to break that part, I would think cracking it by using it as the bb in an enduro bike would be a good way of doing it; in my mind the tube-to-tube is going to be a more durable solution.

ill weld in solid plugs (oversize) and then machine the pivot interfaces faces from them afterwards, so alignment of the suspension points on the first pass wont be as critical for me this time as it normally would be, otherwise I think your plan would also be my plan Earle… evil conveniently have all the difficult bits-and-fits in the swingarm and linkage, so the front triangle needs 3 threaded holes and two pretty loose slip fit through-holes; no bearing bores or anything too clutch.

ill get to drawing and report back with some plates.

3 Likes

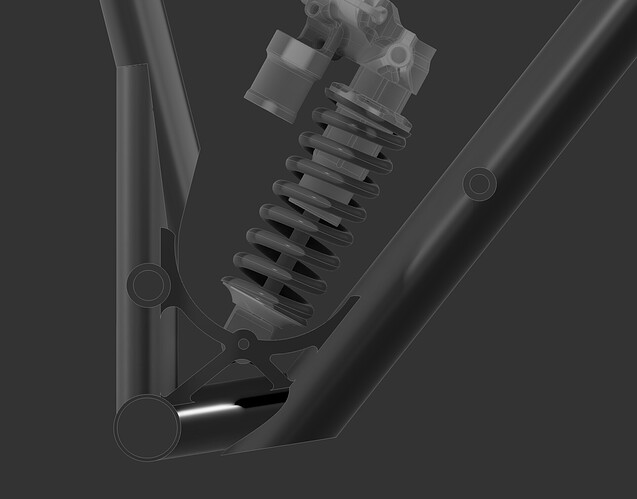

I drew up some mounts for the lower shock eye that I think i’m satisfied with; note that the shock is pictured here slightly beyond the top of its stroke, and as it moves through travel, the top eye moves away from the downtube. so the clearance visible in the lower right of this image isn’t worrying me. reasonably tight getting the very long dropper in there and missing the piggyback at/below bottom out, but again, there’s enough room that im not worried about it.

some interesting reading from vorsprung has guided this design away from where I thought I was going; im building this frame to take one of their Telum shocks, SOLID main piston, get innnn.

https://vorsprungsuspension.com/pages/frame-manufacturer-resources

plates will reference the bb shell and the main pivot, and final bores will be machined after fabrication.

im going to braze these on, because im confident that will be plenty strong enough while to minimising the heat going in.

i’ve had a set cut in 6mm plate and im feeling good about them in the hand.

4 Likes