Looking for thoughts on using braze on seat post binder versus traditional removable seat post collar. What factors drive your decision? Aesthetics, durability, etc. Thanks for any input, Daniel

I prefer the look of a brazed on binder but I prefer the practicality of a collar. If your customer decides to go all She-Ra on the binder, you risk a frame repair. Whereas a collar is easy to swap out.

Typically, I’ll add a binder for road bikes and a collar for off-road bikes. Road bikes look nice as integrated as possible. Off-road bikes tend to be more utilitarian. But some customers request a binder on their off-road machines. That’s fine too.

I guess what I’m saying is do whatever you want. ![]()

Braze on on all my bikes. I do double binders now to spread the load out and need less clamp pressure which can affect dropper posts.

If going braze-on, I’d suggest an old-fashioned two piece binger bolt rather than a threaded boss. That way you can easily deal with stripped threads or seized bolts. But a clamp is easier all-round, both during the build and in use, plus you can add a little bling if that’s your thing.

For road I prefer a brazed on binder.

For gravel and (now) for MTB I’ll do a collar.

And, if I run into an issue like Devlin mentions, I’ll spec an Engin double collar.

No matter which way you decide to go, make sure you put some thought into the wall thickness of the top of the seat tube.

I like to use a thicker seat collar on the seat tube like the ones paragon makes. This adds beef to the top of the seat tube and will keep distortion to a minimum.

Rody (Groovy) has a good video out there on this.

I think ST distortion is the root cause of a lot of frame failures. To be clear, I am not saying binders will lead to failure, there are plenty of problem-free binders in the field.

Seat tube distortion can lead to a cascade of issues:

- you need to ream away more material (which thins it out)

- A non-round seat tube requires higher clamping forces to prevent slipping

- higher clamping forces can break the seat tube or binder

Here is a practical example, for V3 Starling switched from binders to clamps (with an aluminum insert):

My guess is that the decision was driven by the time savings and RMA’s (stuck seat posts, slipping seat posts, etc…)

I think it all comes down to your risk tolerance vs aesthetic tastes

Im pretty sure the alumininium insert was to use a thinner straight guage tube rather than machining or the other hoops I jump through to get a 31.6 seat post into a OD35mm tube.

ALWAYS put a sleeve at the top of the ST to support the binder as well as the TT/SS/ST junction. The sleeve adds some “sexy”, strength and insurance to a highly stressed joint.

I used two brazed binders on my last two frames, and will always do that moving forward. So much less binding pressure on a dropper, especially if you spread the binders generously.

It’s a little more time, but as a hobby builder that doesn’t matter. If I was production building I would probably use clamps due to the extra time and added potential problems.

There are few builders who I’d buy the bikes of, since I can make my own.

English and Bitch’n bikes are the two exceptions. I’d love to have one of Bitch’n’s full squish bikes, and basically anything by English.

To my engineer eye, you can really see that Rob fine tunes everything for the specific riders, especially in tubing selection.

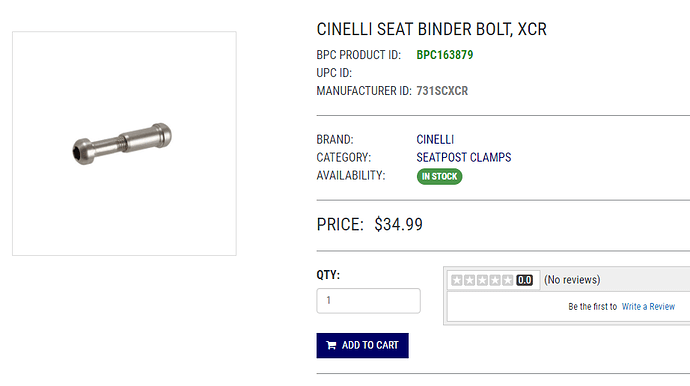

Does anyone have a source for a high-quality, slim (M6?) binder bolt?

This Cinelli bolt is want I need:

Cinelli is owned by Columbus, so my guess is Columbus has it?

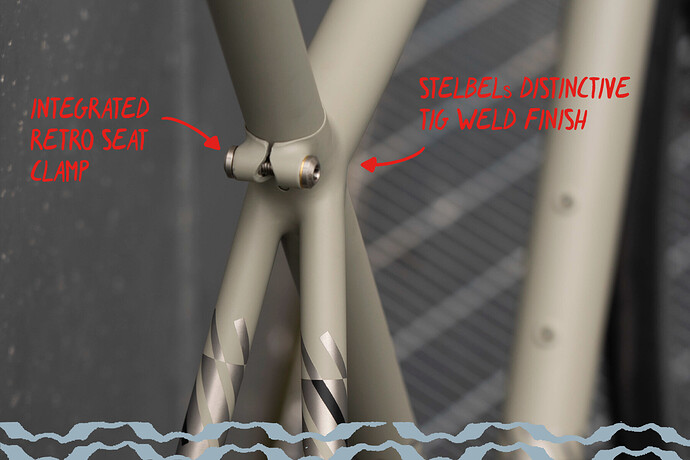

Here is a Stelbel with a similar bolt:

Continuing this thread..

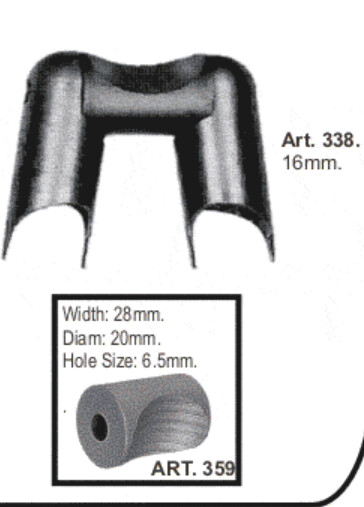

I built a frame with this combined seat stay end and seatpost clamp system.

The seat tube is sleeved with a nice bilaminate, so its a bit beefy. 27.2mm post.

The round and angled top caps have lead to a number of bent 6mm bolts and clamps. I’m now contemplating options. Do I file the round sections flat? Do I drill out the space for the 6mm for an 8mm bolt? Its a bit wide for the standard road seat post securing bolt. I’d prefer an elegant solution.

Maybe try and make some washers that are curved on one side? Could experiment with modifying the domed washers that come with V-brake shoes (if like me you have a bunch of spare ones since new shoes come with a new pair). I think those probably are about 6mm.

Otherwise I would start with a bit of round bar drilled on the minilathe and then shaped with a Dremel and a file.

Or you could maybe 3D print something (or get it printed– I think it would need to be metal not plastic).