I have been using a REYNOLDS CX2472L SEAT TUBE 853 34.1/34.9 X 1.15/.55/.8 X 500. It’s 34.9 at the bb and reduced at the seat post to 34.1 for a 31.6 seatpost. It is a very nice tube, but there are no good two bolt clamps available. Since the frames I’m making will get a dropper, I need a strong two bolt clamp, or else the dropper binds or the post slips.

I have made a two bolt collar and brazed it on. It’s not only a lot of hand work, since I don’t have a lathe, I also don’t like adding threads to a frame when it can be avoided.

I checked, and getting a custom made two bolt collar is not feasible. So, my question is this: Is it possible to turn a piece of 4130 tube on a lathe to the dimesions below and end up with 5" of usable sleeve?

I can see a number of problems with doing this, but I’ve never run a metal lathe so it’s pure speciation on my part.

I would be happy to hear of lathe-free alternatives that will allow me to run a 31.6 or 34.9 seatpost and have a wall thickness of greater than 1.2MM at the seat tube cluster.

Thanks,

Nick

BikeFabSupply has what you need. Andrew can even bend it for you at whatever angle you might need. Then you can use the Engin double bolt clamp.

1 Like

Nick-

That’s totally possible as a lathe part. I would suggest that you don’t need to make it out of CRMO, since the tube is already strong. Really you are just adding a permanent shim. Your lathe guy(or gal) will be a lot happier with an easier to machine material. I’d suggest 303 stainless. It’s super easy to machine and polishes nicely in case you decide to mask it off. I think that would be spiffy and the seat collar doesn’t mar the paint or powder.

If you redesign the sleeve to be a mini collar you can silver braze it on.

1 Like

Just use one of the many single butted options out there. Fairing has them, BikeFabSupply has them, and probably many others. They’re typically .8 or .9 and then 1.6 at the seat cluster.

-Walt

1 Like

@anon68659156 is there a reason you are using that specific Reynolds seat tube?

I agree with the others that in your case, you are probably better off with the 35mm single-butted seat tubes.

As a counterargument, the Reynolds seattube is lighter. Using CAD, I found a 400mm tube to weigh almost 100g less.

400mm seat tube:

Reynolds 34.1mm: - 288g

Tange 35mm: 395g

Tange 29mm: ~220g

IMO the 35mm seat tubes are a bit overkill for smaller mountain bikes, but they win out because of availability and ease of use.

I got carried away in brand loyalty! I really like the 853 DZB tubes with a 1.1 butt at the HT and I wanted a full tube set. Weight isn’t something I worry about. The last frame I made was about 7.2 lbs without paint.

Thanks for the excellent help everyone. I’ve ordered some tubes from bfs and I’ll try to get a stainless sleeve for what I have of the 853

1 Like

@anon68659156

I personally prefer to build up my seat tubes as it give me a bit more flexibility and control over the final shape. It also has the benefit of reducing the changes of reaming through the tube itself if you have deformation from brazing.

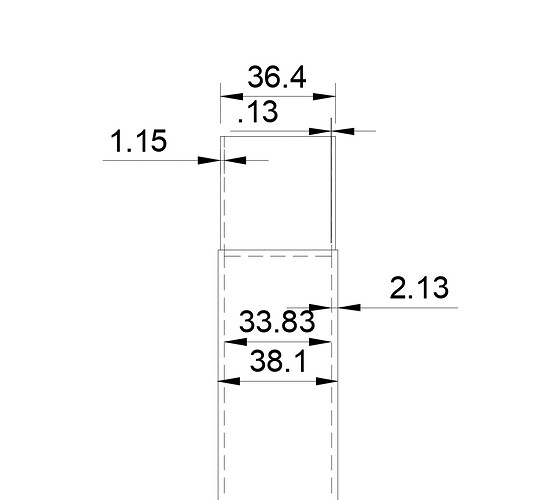

This the seat collar that I machine to work with 1 3/8" 4130 straight tubing with 0.035 wall thickness. The collar itself is machined from 1018 Steel.

2 Likes