i’ve got a couple of personal bikes coming together that ultimately, will need (fully housed) cable/hose guides. admittedly on one of those bikes, the guides wont be in use full time, so a solution that is as “unobtrusive-when-empty” as possible is more of a priority for me than for many.

having become so uninspired by the fully housed cable guide options i’ve basically just stopped using them on personal bikes, my mtb uses the frame bag straps and a zip tie or two, and my latest road bike went internal at the cost of enormous Pfaff, but partly just to avoid the standard external hose mounting options.

i’m going on holiday for a week and likely will do some drawing and pondering in the quiet moments, but if you’ve made, drawn, considered, or seen something you thought was clean, novel, or interesting, and are happy to share it, please do so here! it will be appreciated, and in turn ill post up whatever I come up with, which i’d like to think might have at least some small advantage over the exisiting knee scratching, paint chipped, stress riser, need-a-cnc-or-forge-to-produce, rust traps i’m trying to dodge.

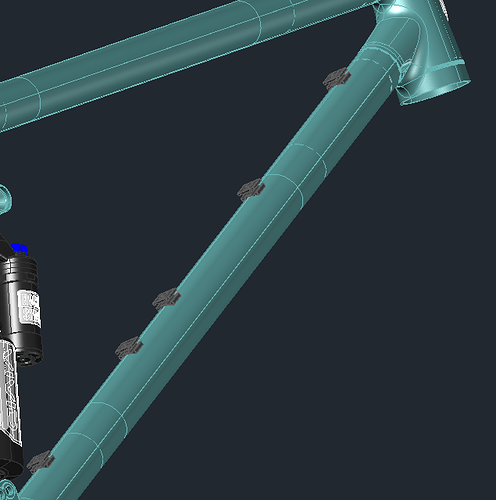

I’m thinking about using those little M3 bosses to screw cable/hose guides on, I think they’re pretty neat!

I’ve long hated using zip ties to secure housing to a frame. IMO it’s an inelegant and wasteful solution. But I admit that it’s super convenient.

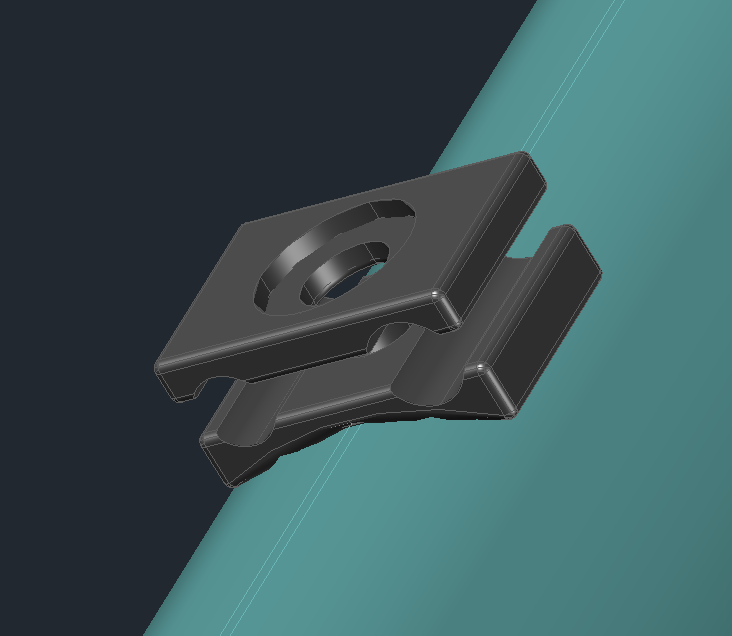

My solution is borrowed from the Rockshox SID fork’s housing guide where the housing is held in place with the magic of friction.

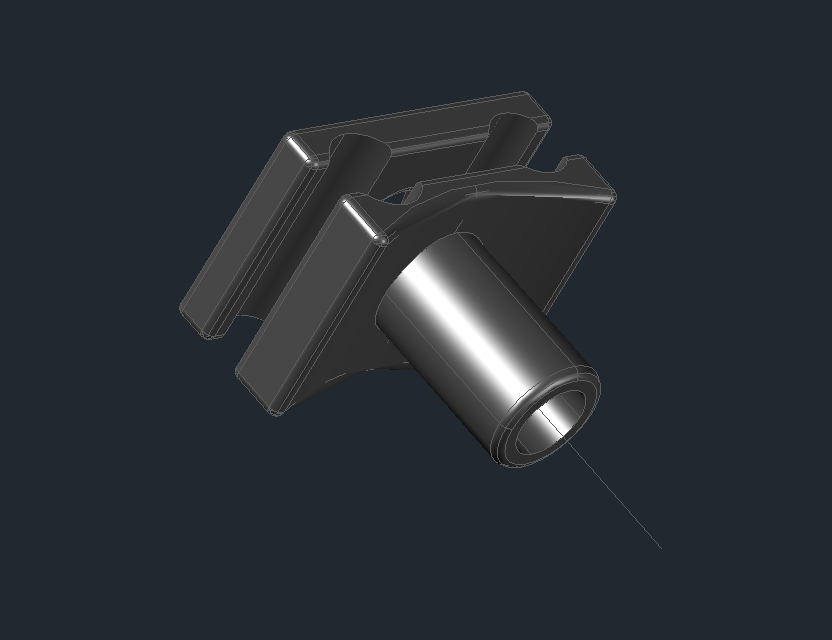

I had a local machine shop make me a batch of M3 bottle bosses. Then I designed and printed bolt-on housing guides. I like the bolt-on solution because I can remove the guides if running a wireless drivetrain and simply plug the M3 bosses.

My guides are fairly simple boxy affairs. But I bet the more artistically inclined could jazz up the design a bit.

You can find downloads of the guide files in the FAQ section on this page to use as inspiration.

6 Likes

I usually install bottle bosses wherever I anticipate needing to attach a cable. I used to work in a machine shop and had access to a bar-fed lathe for personal use, so I did a run of ultra-low profile bosses with 0.5mm stack height and a very large flange, but normal bosses would work just fine. My guides are parametric in fusion and have adjustment for the tube diameter, housing diameter, and number of cables. I’ve been printing them out of CF-PLA or PA-CF and they have held up very well. I like that the housing stays right up against the frame and doesn’t flop around in space like all the braze on guides that keep it off the tubes a few mm.

3 Likes

I did up some top of down tube ones the I 3d printed in petg and they have stood up well. The mounting is a flow drilled hole and roll tapped for m3.

Nice part of custom 3d printed is that I could do them to the exact diameter of the housing and the tube for a nice snug fit.

Will do something similar for the rear end on the next build.

3 Likes

thanks for each of your replies team, it seems like some custom m3 bosses and either some snap fit printed clips or “over the housing” clips are in order (nice to be ale to try both interchangably.)

I kinda love the flow-drill,roll-tap move but it also terrifies me (because I’m ignorant, and scared of stress risers, * stress rises *).

Earle, next time you flow drill/ tap that downtube can you film it for me?

1 Like

I’ve done a 3D printed base with a split clamp style top. Can be either resin, aluminium or stainless top. I’m running the cable off the surface so that the frame can be hosed down easily when muddy and the housing doesn’t catch the mud against the frame. Plus no rubbing on the paint. Base has an M4 thread and is silver brazed to teh DT…

6 Likes