@jimg great idea! I love the wooden shovel (?) handle on your bender. Very classy haha.

I have been inspired by everyone’s DIY tooling on the forum, and it got me thinking. The state of frame-building tooling is always in flux. Unfortunately, a lot of great tool makers come and go along with their knowledge and product support. I think an open-source, community-driven, tooling and fixturing ecosystem be beneficial to amateur/hobbyist builders. Laser cutting services, 3D printing, metal 3D printing, and basement CNC machines are getting cheaper while people’s cad skills are getting better.

Konga Bicycles sets a great example: http://www.kongabicycles.com/

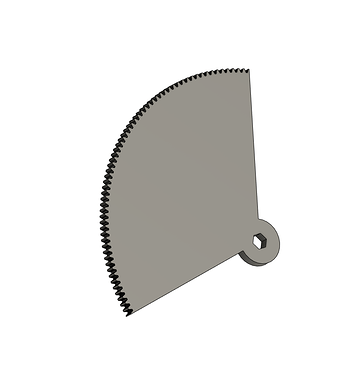

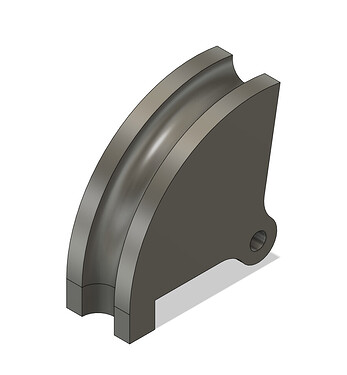

Last night I spent some time brainstorming a laser-cut, 3D printed, geared tube bender that uses hardware (gears, shafts, bearings) from FIRST Robotics: Gears — AndyMark

Tube Notchers:

Let me bring in a cool conversation with @StratoCycles @Mikesbikester and @anon91558591 from this thread: Anvil Tube Mitering Jig - #18 by anon91558591

From @StratoCycles:

This might be relevant to the discussion. I modified a Pro-Tools notcher to use with a jig I made. The jig used 3d printed tube blocks and worked great. Bit cumbersome to setup but worked for the first couple frames until I got a mini mill.

From @Mikesbikester:

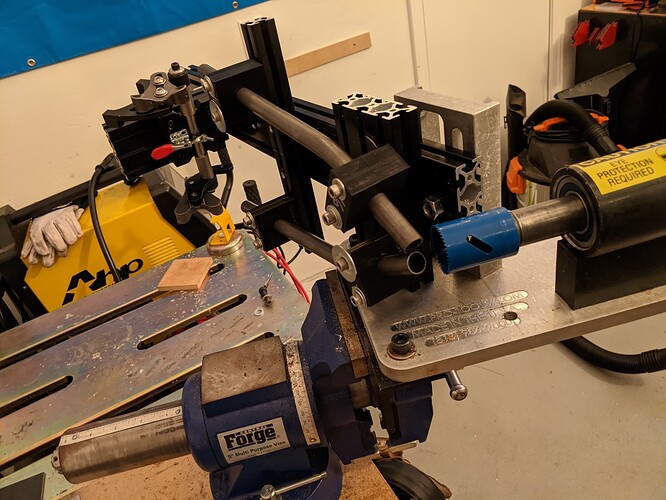

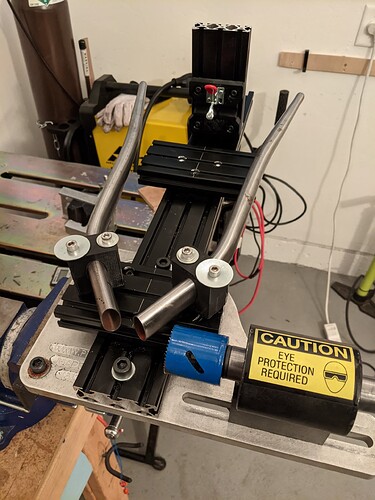

Tube notchers! When I look at these relatively inexpensive notchers I see the same issue as @anon91558591 with the tube clamping allowing for chatter. They also tend to run out of angle pretty quickly. The way the notcher is constructed with a long bushing, then a really long shaft with a hole saw on the end leaves additional room for chatter. The third issue to me (which was previously called out) out is the fact that there’s no way to control the feed rate. To me when working with thin enough tubing to make a bike out of, it’s pretty important to have good work holding, good hole saw holding, and some form of feed rate control. Fine tooth hole saws are a way to mitigate some of the issues of a tube notcher, but I still don’t think they really fix the rigidity issues which can result in notches being off center.

The work holding and hole saw rigidity issues of the inexpensive notchers available drove the design of the notcher that I made. Then when I needed to use it on bike tubing, it only took the saw grabbing one time to know that it needed a feed screw.