so I built a fat bike for a buddy and well the seat post is binding, I have reamed it and all that with a adjustable reamer but i cant seem to get it. slide the 210 one up dropper in there and drop it down and it binds, The post is fine out of the frame, its like the seat tube is bent and when you snug up seat binder bolt ( welded on seat binder braze ons.) it puts opposite pressure on the post…

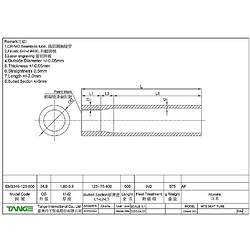

it seems like a long bladed 31.6 seat tube reamer would sort it out but the adjustable ones have shorter cutters so it just seems to snake in the seat tube, it is a butted tange seat tube I keep reaming it out little by little, i don’t want to do to much as it seems to be more open at the the binder bolt now but tight lower down… uggg what to do…

If you don’t do the binder up does it work? If the seat tube does have a bow in it you could run a 30.9 with a sleeveat say 100-120mm long

I would suspect the binder is the problem. In my opinion the area of the binder pulls flat when tightening due to the bolt having no pivot. Seat clamps usually tighten into a barrel, I think that helps. Before reaming anymore I would consider taking off the binder and using a seat clamp.

The first thought I had with the snaking reamer comment was adding a bushing to follow the cutter and add a little more support - no idea if it’s feasible with your setup though.

I use two binders on my frame. So it grips over a bigger area with less torque on the bolts. I barely do

them up.

It sounds like the binder is the issue. How much torque on the binder?

We don’t use brazed/welded binders because they will always deform the seat tube and post more than a well designed two bolt clamp.

Whatever you do, stop reaming the seatbtube, you’re only going to cause more problems. Those tange tubes don’t require anything more than a light skim

I think slot length has a lot to do with clamp distribution. I did not slot my first frame deep enough and I have to cinch the collar incredibly tight to keep it from slipping.

This is the rig pre paint

The dropper post is a 210 one up and deep in it’s travel it gets stuck. its like the top tube and seat brace are pushing in opposite directions and when you tighten the binder enough to prevent it from spinning in there it bowes the post… we did drop a regular 30.9 post with a canecreek shim in there to see if it clears its ok but maybe i will get the same dropper post and slide it in there… it seems if i had a long reamers it would work but around the binder its gutting a bit loosemaking things special in other ways

first of all, sweet frame! I like the yokes and the fillet brazing.

Did your SS’s make it onto the butted section?

The Tange tube calls out the butt to be 125mm long:

Does the seatpost go into the frame easily? I think it’s possible your seat tube banana’ed because of your TT and the brace, but I find it unlikely that tightening the collar would cause it to “straighten out” and bind. If it were banana’ed that much, I feel like the act of shoving it in would cause it to bind. I still think the more likely explanation is that the collar is binding.

Metal seat tubes and dropper posts are finicky. Seat post and seat tube tolerances are all over the place. Because of the tolerance stack, we run into slipping droppers from time to time with single bolt wolf-tooth clamps. Now we exclusively use two-bolt clamps, 60% of the time it works every time (joke)

I love the look of an integrated binder, but I think it is important to evaluate designs in the context of componentry. When integrated binders were invented:

- lugged construction was popular

- there were no dropper posts

- seatposts were aluminum (you could crank on the seat collar)

Modern Droppers and carbon seatposts require a delicate touch. Not saying integrated binders don’t work (again, I love how they look), but they certainly carry risks. There is so much tolerance variation among seat tubes, seat posts, seat collars, and distortion from welding.

Cool looking frame!

Double brazed binders have worked great for me, but using a seat tube topper instead of a butted tube, which I think gives a bit more clearance.

Not to derail the thread, but have you tested for heel clearance at the seat stays? I learned it’s an issue on my fat bike frame.

At the very least, I’d cut the binder slot another 20-30mm. If it’s too short, the top edge of the tube pinches together as you tighten the bolt; the longer it is the more even clamping you get along a longer section of tube - therefore greater clamping area on the seatpost, less torque on the blot and less deformation of the tube. You could also try adding another binder bolt and lengthening the slot even more.

Failing that, use a decent clamp, ideally double bolted.

ya I made this frame with massive tire clearance maybe a bit to much could pro fit a 27.5 x 5 in there if there was such a thing… and heal clearance is a bit of a worry but the rider is using it and has smaller feet then me and is having a good time…

we have put a half shim taking out some the snaking clamping force and that has worked… I might invest or make a heat sink for seat tubes, bb wouldn’t be a bad idea either…

ya Daniel the there is some resistance once you get the seat post where the TT and ST meet. the brace also I think has something to do with it all… I did use nickel silver to weld the brace which gets hotter but looks clean with tiny fillets… maybe I will just do brass to keep heat down… I would love to make a 3d print topper that addressed all these problems, I also dislike mitering seat stays to seat tube hence my yoke type design,