Your head badge is 100% certified radical. Love it.

Thanks. I kinda love it too. Makes me feel better about not having a name on my bike frames.

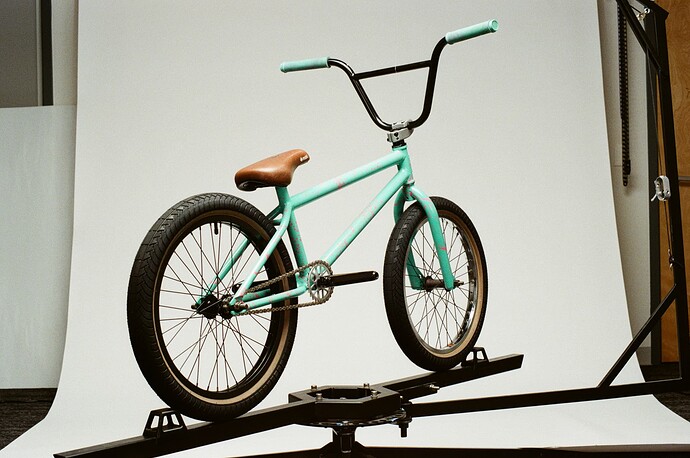

I’m gonna just post a little tease here until I get some proper photos of the completed bike.

Tire is a 2.4" tire and the rear wheel is basically slammed forward in the dropouts. The chain has a half link and if I loosen the axle nuts, the wheel can move forward maybe 1-2mm. I love it. It’s a bout 12.6" chain stays where the wheel sits now. Sprocket is a 25T. Which is what I wanted, but I literally can’t go any bigger. Head Badge is stainless.

So good! That paint! ![]()

![]()

![]()

![]()

yeah that’s so sick

This is so rad

so good!

Absolutely killed it. I can‘t stop looking at it. 2 very enthusiastic thumbs up, 10/10, would recommend to a friend.

Thanks. It went pretty smooth. It took 5 months but really only about 10-12 actual days over those months. I’m a fan of the seatstays to top tube junction. I hoped it would flow well.

I think my favorite photo is the head badge photo though.

I had a full day in the shed and finally received my small package of tubing so I finished my Nalgene project.

I got the 1/4” stainless tubes from Aircraft spruce and the stainless mounting plates were laser cut from Send Cut Send. I have two benders. One is 14.7 mm radius and the other is 25.4 mm radius.

It took a minute to get my measurements and process all figured out to be able to repeat the process for all 4. I marked the first rod every inch before I started bending so that I could know where each bend started and ended. The larger radius bend under the bottle has to be the first bend since the tubing will only fit in the tool of it hasn’t been bent anywhere else yet. Even with the measurements I’m surprised how much difference there was in the length of the cutoff at the end.

I’m pretty happy with the result. Only had one cage that’s a little too wide and is gonna need some low profile bolt heads so that they don’t interfere with the way the bottle sits. The true test is gonna be actually using them for some bikepacking.

Looks good! Did you insert a small rod where the 2 ends meet or is it possible to just butt them together and braze it up?

I did insert a small rod (cutoff piece of random metal)

I wish I could have found something that fit better, but I’m not a perfectionist and I didn’t want to wait any longer to finish this project.

Oh shit! It’s happening again. I need to mount some canti bosses and I’ve pulled out the charred piece of wood jig. One of the brake bosses had snapped on this fork and hopefully this jig will last long enough to fix it. Fork is from an old Schwinn Mirada.

How do you all deal with paint matching after a repair?

Get it close enough and not worry about it. It’ll soon get a bit muddy and no-one will notice.

Brazed the posts on and they are straight enough and better than before.

Now just gotta soak off the flux and find some blue paint. Brake bosses that are worth more than the fork they are attached to, but I had them and this will get the bike back up and running.

since I had the torch lit, I decided to also move on the chainstay dimple tool. I’m not sure if I’m gonna use a wood block or angle iron, or some cut off tube for the other side, but the dimple side is done.

HA! I caught my frame jig on fire the other day. It’s a proof-of-concept using particle board. Good times!!!

I think I’m pretty happy with how this is turning out. The jig is straight when I check with a fork that I have on hand. It’s not too hard to set up. This fork has a 380 mm axle to crown length and a 48mm offset. The fork crown will clear 45s easily and I think I can run up to a 38mm tire with fenders.

I’d like to figure out a better attachment to hold the steerer, but for now, this will do. I’m moving to a new house (and a much bigger workshop) in 2 weeks, so I might not get this fork done before then, but the first cyclocross races start up the end of August so I will be under the gun.

I should probably explain this bike a little bit. I’ll put up a post on that soon.