Hello everyone, I wanted to ask everyone how far tubes can be squeezed. and what role does the wall thickness play? To what extent does this affect stability? Or will the tube be weakened?

Do you have more details on what you are trying to do? Toptubes? Chainstays? Material?

Here is a good thread:

All chainstays are “ovalized” by a forming press:

The 30 x 16mm chain stays that most tube suppliers sell start life as a 24mm OD tube, so that degree of ovalization is a good place to start if you’re looking for a rule of thumb. I’d be reluctant to do more than is absolutely necessary, though. This may be one of those things were the eye test is a useful guide, i.e. if it looks like too much it probably is too much.

When I’ve experimented with ovalizing tubes, the centers will crease a bit if you go too far and don’t use a form to control the shape. Something like the image below. Depending on how the tube is painted/illuminated this could look pretty bad, imo, but I’m not sure it’s any worse structurally.

Kris at 44 squishes his to flat and seems to have success with his chainstays. I try very hard to design without the squish but sometimes a tweak here and there is needed.

want to squeeze a 0.9mm wall thickness OD 28.6mm tube down to maybe 18mm. My plan was to print a forming press with the 3D printer. Check the fitting and maybe mill it out of aluminium.

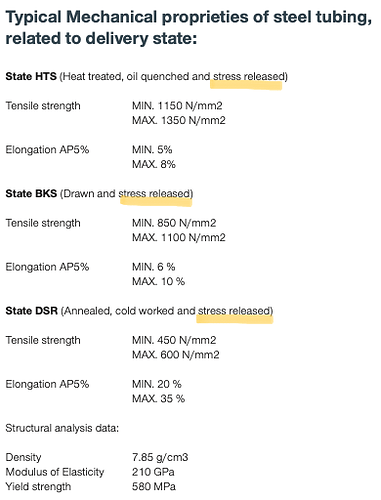

@Daniel_Y On your trip to Taiwan, were you able to see whether the manufacturers stress relieve tubes after forming (bending/dimpling/ovalizing), or complete frames after welding? I’m assuming they do this at some point (probably after swaging/butting?), but thinking about it some more 24mm OD → 16x30mm oval + dimple would really be quite a lot of cold work.

For steel, I am pretty confident they don’t do any stress relieving. I asked why they don’t heat treat the entire frame (to normalize the HAZ), and our guide told me that people have tried in the past, but the frames warp too much during the heat treatment process.

With regards to stress reliving individual tubes, I don’t think this happens either. The coldworking is used to strengthen the tube. A conversation with Fairing (tube manufacturer):

Regarding the 31.8x.8/.5/.8-600mm tubes, the mother-tubes (blank tubes) will also reflect the hardness. For example, to make this tube the factory has to start with the next biggest size, 34.9mm, and draw down to spec (I forgot how many passes but at least two because for each butt). BUT if 34.9mm tube is not available or a shortage, they would use the next biggest size, 38.1mm. Using a bigger OD will make the tube a little harder because of more drawing down needed to get to spec. And yes, they have to anneal tubes prior to cold drawing to spec.

Summarizing: Tubes are annealed and then cold drawn. The cold drawing work hardens the tube to achieve its final strength and hardness. Depending on the raw stock size, some tubes will have more cold work (and are harder).

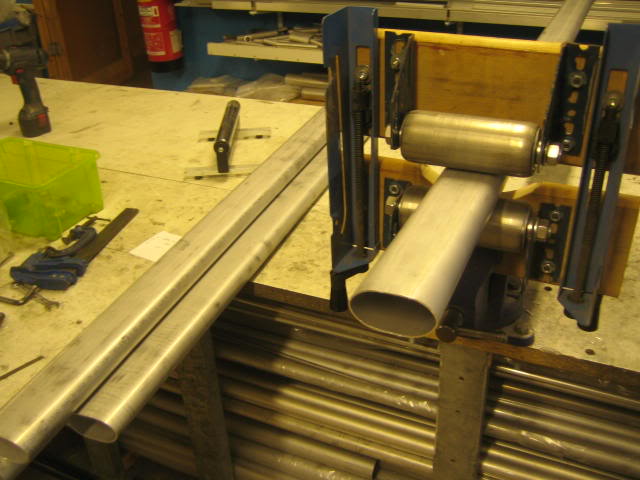

This was the chainstay press from Maxway:

It was interesting was the adjustable dimple:

The floor manager would double-check and fine-tune the dimple before every run and compare to the 1:1 drawing. I saw a kinked dimple nearby, so I wonder if there is some chainstay-to-chainstay variation that requires adjustment. Or maybe that was just the initial run?

For titanium, totally different story. I still need to learn more about it.

Thanks for the info! It is fascinating to see production tooling, it is totally different from what custom builders use. I started to doubt my initial recommendation after noticing that the Dedacciai Zero Uno catalog describes most of their tubes as stress relieved, but if the Taiwanese manufacturers do without it there’s no reason to be too concerned.

This is an interesting find. The factories I saw formed their own chainstays in-house in production, so maybe they avoid the stress-relieving step out of practicality and cost savings.

In my experience, the CS dimple carries the highest risk. It seems like the factories have empirically found the optimal dimple and ovalizing shape to reduce that risk. This is just speculation (I can update the thread if I find out more), but they probably use thicker gauge steel or plain 4130 for chainstays to improve the workability and reduce risk.

Rather than pressing, I used to form 1500mm long aluminium flat oval by manually pushing through a set of parallel, but adjustable width steel rollers several times.

Home built at almost zero budget when I started the company (Hacked Black and Decker Workmate with some steel shelving angle and two used conveyor belt rollers), but it lasted over 20 years and processed over 1000 tubes.

1.5 x 0.049" (also up to 0.065") cold-drawn seamless 6061-T6 formed down to 40 x 88mm approx flat oval, so just over 2:1 fineness profile.

This gave a really good, flat-sided and round-ended section, without the central crease or a pointed crests that are typical of pressing.

In my experience, this method has far less effect on the material strength at any single spot than a single pressing does, since for each successive pass through the rollers, a different area of material is slightly deformed…essentially, the flat spot starts out at the top edges of the tubes, then gets progressively pushed outwards as the tube deforms.

All the best,

Dan Chambers

Hello, I have a question about internally Double butted tubing. How do they remove the inside mandrel after doing the second Butting because the tube is thicker on the outside edges so the mandrel will be stuck inside ?

They spring the tube out bigger diam with some trick with rollers, at a slight diagonal IIRC, and the mandrel can be pulled out while the tube is sprung out. I think I remember hearing that was what Reynolds patented way back whenever. Teens, twenties?

The amount the tube can be made to spring out is limited, so that limits the butt differential — how much thicker the butt is than the unbutt. You can have a thicker butt than that, but at one end only — you remove the mandrel from the other end. Like “Logic” and some so-called “triple butted” tubes (which are only double butted. “Triple” works as jargon, but it’s really more a marketing term.)

Try filling the tube with sand tightly before pressing. May be it can give better result…

Hi all

My question is probably a little off topic, and the thread might have gone cold, but I was wondering if it would be possible to anneal and press aluminum tubing on a bike frame, particularly the chainstays, to make space for a wider tire (35mm).

I am considering this and would fixate the whole bike, and press with the lever mount on a pivot, somehow, up against a piece of wood. I haven’t completely thought it through.

Only allowed one picture as a newbie. The bike in question is a Klein Quantum. The triangular reinforcement gusset, or whatever it’s called, is quite large.

Thanks in advance.

Hello again, found the thread on chainstay dimpling. Now my only question is how close to the gusset can I go?

I’ve never attempted indenting alu stays, but I’ve heard repeatedly that it can’t be done without splitting/cracking.

Sorry to say, but the solution is (1) sell this frame and (2) buy another with enough room for the tires you want.

Alternatively, buy a steel frame, which can usually be indented further without ruining it.

Thanks for this, Bulgie. A 650 conversion is probably the way to go.

Yeah give it a try, but with some indented stays, the width between them doesn’t increase much (if at all) as you go back the difference between 700 and 650. Yours looks to be one of those. Some are even a bit narrower when you go back that amount, if the indents are especially deep.

Do you know about the Rossman tire fit gauge?

Cheap and quick to use, everyone here should have one. No I don’t sell ‘em, just a satisfied customer.

Don’t forget about the lowering of your BB when going to 650, unless you can use a pretty big tire. Maybe you have plenty of BB height and can afford to lower it, just be aware.