Hi there,

What are your procedures for ss mitering? Which dimensions do you use and how do you use them in reality? I usually try to cut the dropouts end first and than use somehow figured out length to seattube cut. But I can never get it right at the first time (and also getting seatstays at seattube end close enough takes some fiddling). It’s the most difficult cut for me and a real pita.

How do you do it to get it repeatable and easy?

What arrangement are you using? Fastback where they butt up against the seattube? Those seem to be the hardest and most fiddly without specific mitering fixtures and such.

They are still the hardest cuts I have to make, even now that I have a horizontal milling machine and a Farr CS fixture that’ll do SS as well. I build the rest of the frame first, and use a giant calipers to take a few measurements and make sure my BikeCAD numbers are still good, then set my vise with a little sine bar after I’ve made the dropout cuts. I can do pretty darn well. With templates and files, it was tough and I had to live with some sloppy fit-ups.

What do you have for tools?

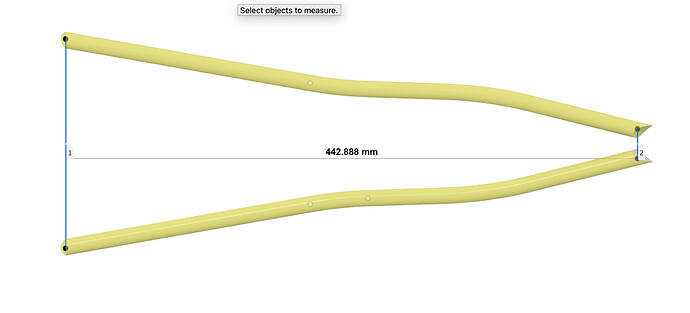

@Nick2 @Duanedr I have a vertical mill and a jig similar to FARR/Cobra that I’ve made. In theory - I do it in a similar way, that you’ve described. Which measurement distance do you use for cutting? I try to use this one (a I am cutting the stays upside down):

The farr miter fixture has a datum that represents the center of the seat tube when I use it in the arrangement pictured. I use center of the dropout to that datum to make the cut. I make other measurements in bikeCAD using the right-click measure tool to compare the frame to the model and generate measurements that are easier to make with a caliper so I can ensure things haven’t drifted too far from my design and adjust if they have. Using round dropouts makes it a lot easier and more forgiving if I make a mistake. If I cut the SS a few mm too short, they just land a bit lower than I intended.

I don’t generally use that fastback type arrangement. It always seemed, regardless of what fixtures or fittings I could conceive (and I built a couple), it was a bit of a guess because I had to make up all of the other variations that have accumulated along the way. I’m sure some dudes who have their processes dialed and repeatable have found a way but I ain’t that dude.

I’ll add that this is probably, IMO, the least forgiving method of attaching seatstays.

I usually use side mounted seatstays or wishbone and they minimize some of the problems. At least this has been my experience.

I’m in the same boat. There really isn’t a good, easy to use measurement in BikeCAD when it comees to SS’s. I wish BikeCAD had a either a better way, or more variations when it comes to getting SS measurements. I would think that it wouldn’t be too difficult to have an option to calculate length based on which DO’s you input and how the SS are attached to the ST. With everything else that BikeCAD is amazing for, I think the SS portion of it is lacking.