Hello everyone, I’m looking for some advice on this project I’ve been working on to improve the handling of my S5 Stumpjumper Evo by replacing the seatstay to lengthen the rear center. Just to preface this, I have no engineering experience beyond a few simple 3D-printing and CNC projects.

To accomplish this, I machined some aluminum “dropout” plates and ordered some 3d-printed aluminum arms on Craftcloud. I decided not to replace the stock chainstay to save money. I’ve been riding this setup for around two months, including a handful of bike park days, and surprisingly it seems to be holding up just fine. Here’s a photo of how it turned out:

The one issue with this project so far is that the replacement seatstay assembly ended up being extremely heavy (at least five times heavier than stock), so the rear suspension felt noticeably worse. I did design the arms with some internal passages in the hopes of saving weight, but I didn’t know that I needed to add escape holes for the powder, so they are quite heavy. I think the next phase of this project is replacing the 3d-printed arms with a lighter version, which is why I’m making this post.

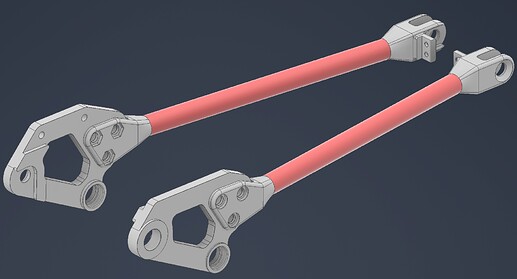

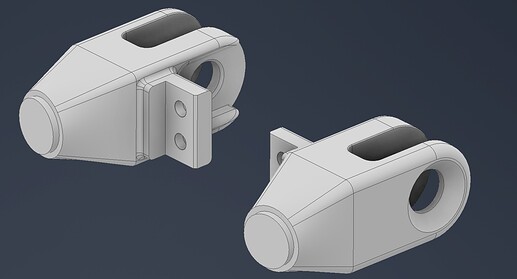

After some research, I think the easiest way to do this would be to order some 3d-printed titanium “lugs” and weld them to off-the-shelf titanium tubing. I’ve thought about trying to bond carbon tubes with titanium connectors, but it seems like designing a bonded joint takes some trial and error and is a bit beyond my pay grade. Here’s what I’ve drawn up so far:

Obviously the “lugs” or connectors need some refinement and internal structure in the tapered sections. I’d like to keep my “dropout” plates for now to make experimenting with different rear centers easy, since I can machine different versions myself. I don’t know how to weld and I’ve never designed anything for welding, so I have some questions.

-

I’m thinking of using 0.750” OD tubing (based on my titanium gravel bike frame), what wall thickness would be appropriate? Something in the 0.05"-0.06” range?

-

What tolerances should I aim for between the ID of the tube and the OD of the lip on the connector, and how long should the lip be for best results?

-

Is there a way to design the joints to ensure that the connectors end up parallel (without any axial twist along the axis of the tube), or is that just down to careful setup of the welding jig?

-

Any other general design advice? I’m open to any feedback.

Thanks for looking.