Ah, makes sense! I’ve been wondering since I noticed how much the head tube “whips” on my niner- fast chundery descents get the fork flapping like a loose serpentine belt. It’s probably only a few degrees of deflection but it’s unnerving.

From a theoretical standpoint, there is minimal difference in stiffness between bent or straight DT. The bend is just for crown clearance, as bustrucker points out.

Early 2000’s 29in MTB’s have bent downtubes because the headtubes were steeper (68hta) and reaches were shorter (420mm).

Slacker HTA’s and longer reaches create more crown clearance, which allows for a nice straight downtube! We use straight downtubes until we get to our M size, which is ~430mm reach and 66.5HTA

I’ll say! I admit to ogling a few of those beads on instagram.

The bike looks amazing… but is that a fretting hammer?!?

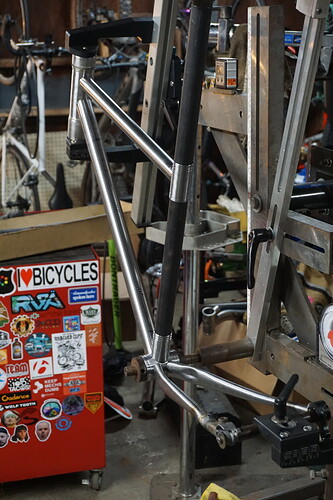

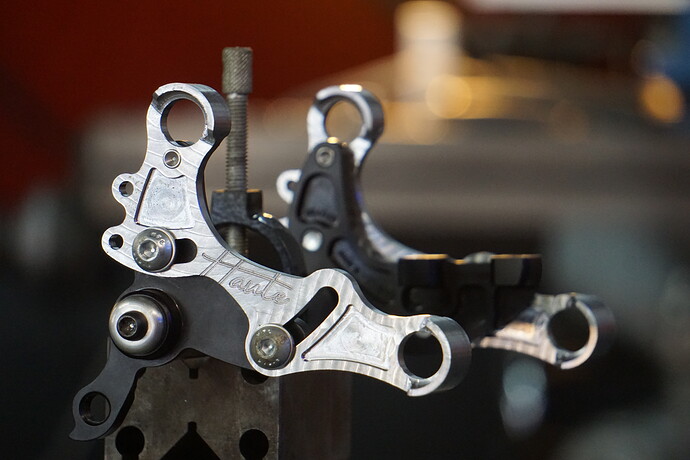

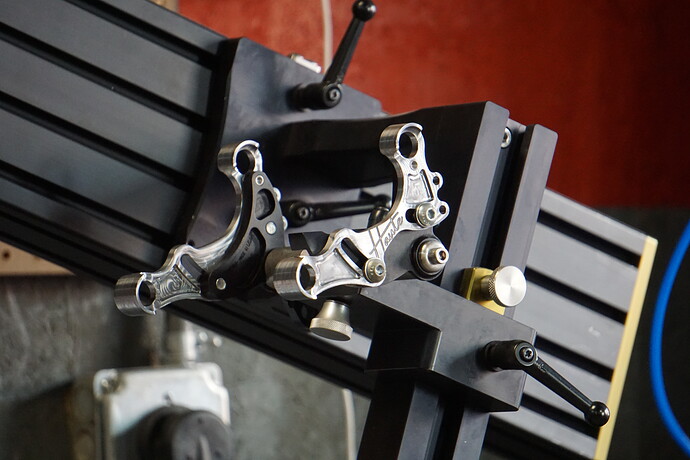

If you haven’t heard, I’ve started a new venture called Haute Bicycle Co, this time with @Wilson . He’s an aspiring frame builder but is mostly handling the sales and logistics side of the house for now. Our goal is to lower our costs and the price of our bikes by building in batches rather than one off customs. Seems alot of people are headed this direction lately.

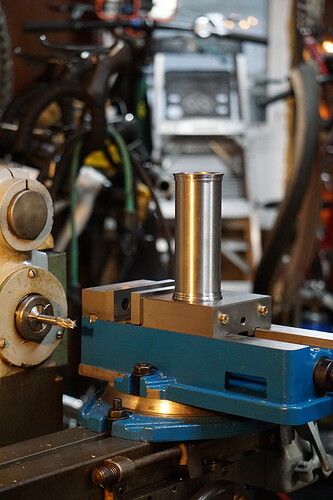

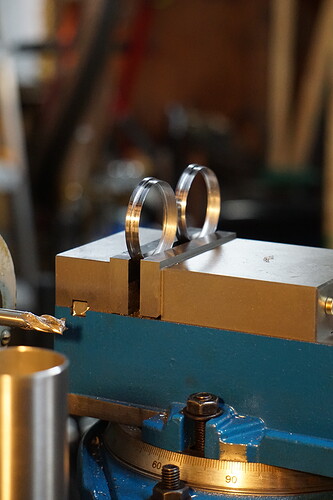

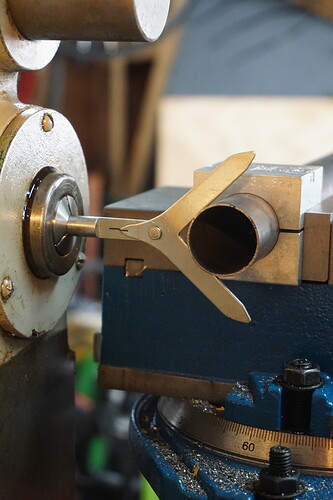

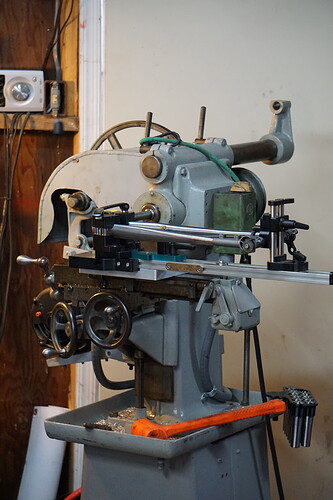

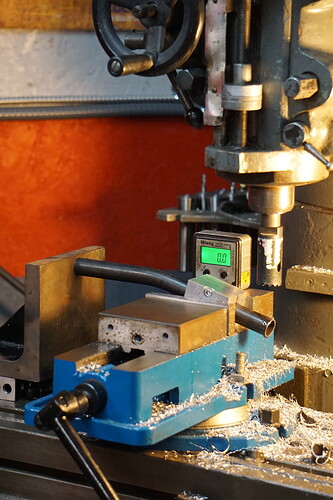

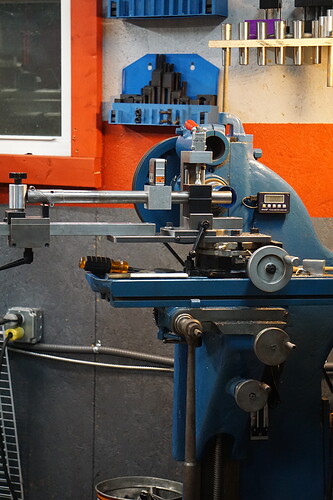

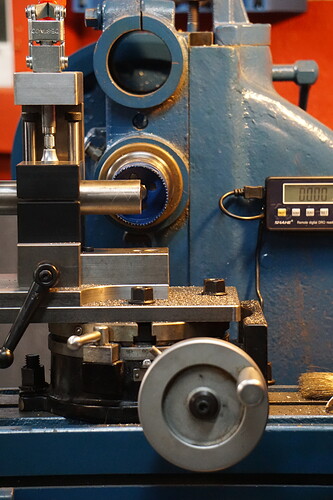

Anyway heres a photo dump from our first run of gravel bikes called the Haute Sauce.

Hope to have some nice glamour shots of some completes soon…

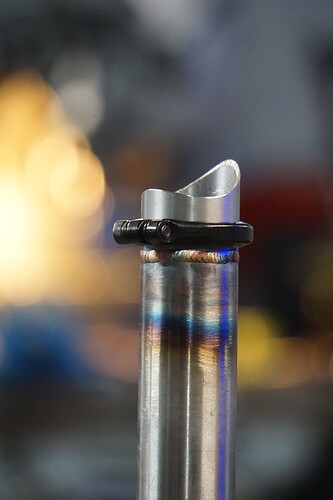

Quite pleased with my latest tig welding exploits ![]()

Happy new year!

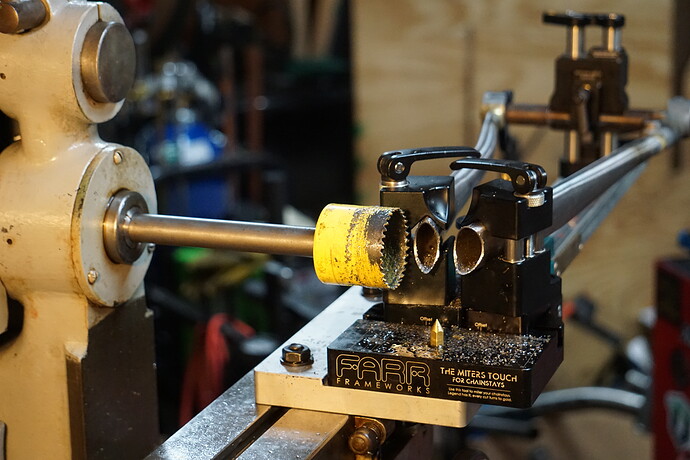

May your miters be tight and your dimes stacked in 2024

Wow! The welds are looking good. How many hours to get to those dimes?

What to tube is this? I really like the oval with tight edges.

I got my welder in Nov of '22.

Unsure of hours, but since then i’ve done at least 50 practice tube-tube joints.

I’d say the majority of the hood time has been welding >300 t-bars.

This is the 8th frame i’ve tig’d.

This is just a 25.4 round columbus tube that I smash with some wood planks and a vise.

Whew!!! Haute stuff over there ![]() Super well executed, lovely finish work, and some delightful details in there!

Super well executed, lovely finish work, and some delightful details in there!

I’ve also been curious - is getting the Ritchey breakaway parts as simple as sending their sales team an email?

Thanks Eva!

Indeed it is. The person you’re looking for is Simon.

sbeatson@ritcheylogic.com

Very clean looking.