I don’t mind a well executed internal run. Even as a mechanic it wasn’t that bad once you worked out a few little tricks. Then you get to through the head set routing and you can stick that up the proverbial. The original Venge was a bastard of a bike that nearly made me give up being a mechanic. I was good at sorting them out eventually. Thankfully Spec redesigned that set up. It was still shit though. Good thing was seeing how not to do inetrnal routing when it came to building my bikes.

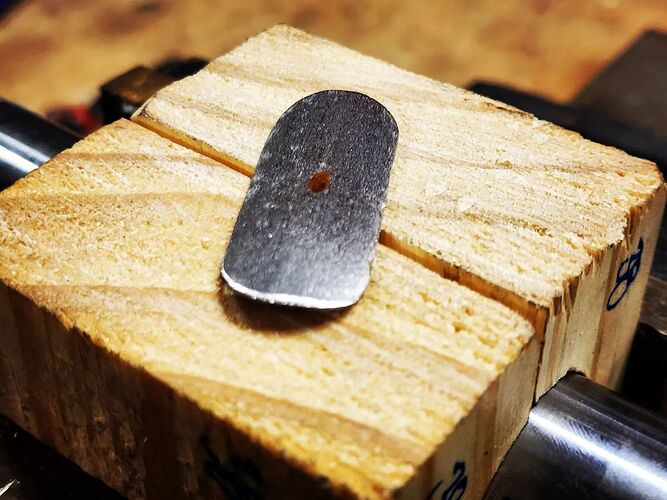

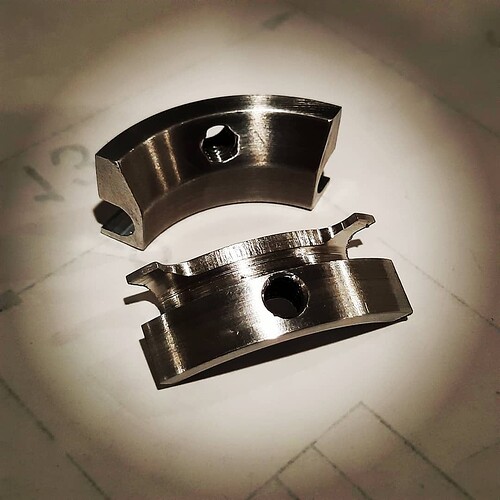

My approach has evolved a little over time but one thing I have always done is reinfroce the penetration in the main tube. I choose to do it internally as opposed to an external plate. There are pro’s and con’s to either but I prefer the cleaner look the internal plate gives.

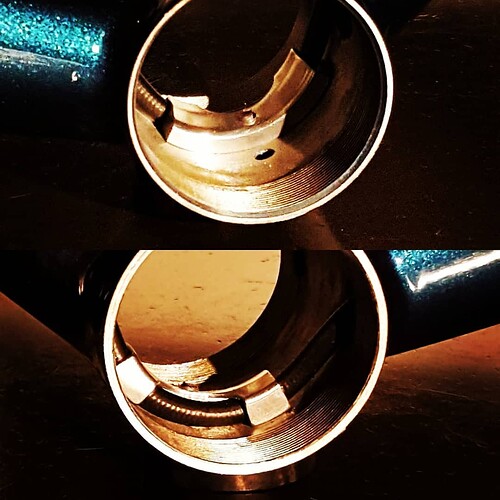

Below I have photos of a DT rear brake run. Enters drive side top of DT and exits NDS bottom of DT. Wraps under BB and along underside of CS.

I use the same method for road rim brake lines. Just adds to the ultra clean lines you can get and is easier to run than interupted housing and cable stops.

I’ve done a few bikes, mostly road where I run the hose through the chainstay via a T47 BB shell and a brass guide tube. These are quite fiddly and only do that if the customers wants complete internal.

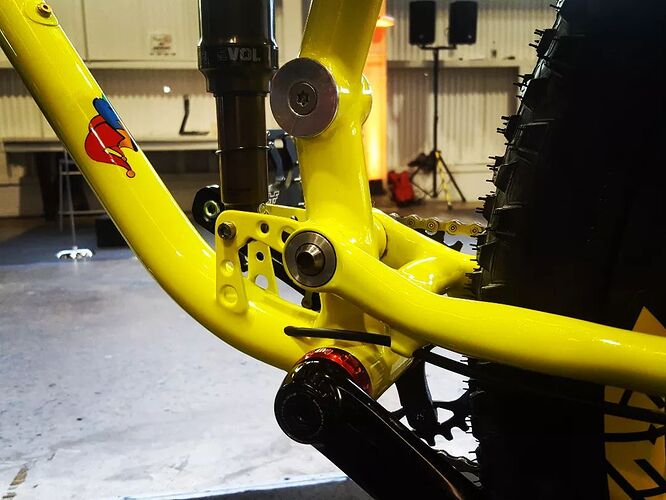

The mtbs, so far I’ve done a mix. All have been DT internal with the first bike being through the CS and the rest being along the underside of the CS. I will stick with the later setup for now with full internal guides tubes.

I’ve also done a bike with full external. A little town commuter style bike.