Totally makes sense! My concern comes from wearing down the plastic coating to such an extent that water/muck could get into the housing. My worry comes from the mtb mindset- even then maybe it’s a non issue

Personally, I cannot stand internal brake and shift lines, massive pain to work on fully guided path or not. If I’m buying another mass produced MTB frame it will either be externally routed or I’ll use stick on cable guides.

Droppers need to be internal at some point (for modern posts). Did a stainless tube brazed in the DT which worked well.

I like that. Will likely copy ![]()

![]()

![]()

Are those butted tubes? I would have thought you could see the effect of the butting in the fea results.

The Flanimal looks like the ports have to be outside of the butted area. To me, that seems like a bad idea. But the required testing may not really stress that area so much. Someone upthread mentioned dropper ports. I agree internal dropper routing is really nice to have. But it seems like the sides of the seat tube/bb joint are really highly stressed. Or maybe that’s just for those of us that have a square pedaling style.

I don’t mind a well executed internal run. Even as a mechanic it wasn’t that bad once you worked out a few little tricks. Then you get to through the head set routing and you can stick that up the proverbial. The original Venge was a bastard of a bike that nearly made me give up being a mechanic. I was good at sorting them out eventually. Thankfully Spec redesigned that set up. It was still shit though. Good thing was seeing how not to do inetrnal routing when it came to building my bikes.

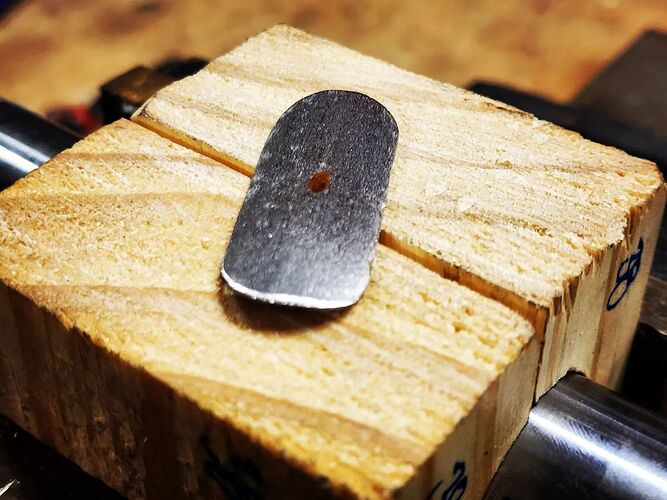

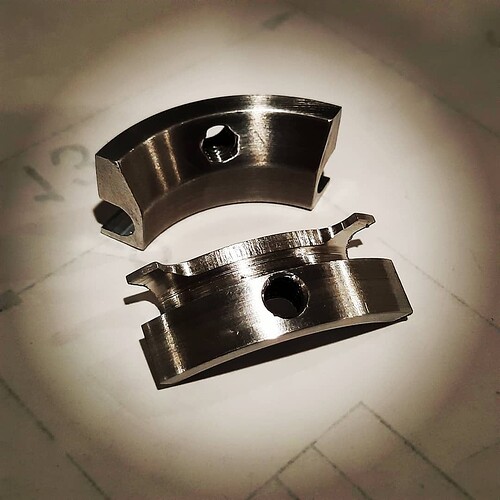

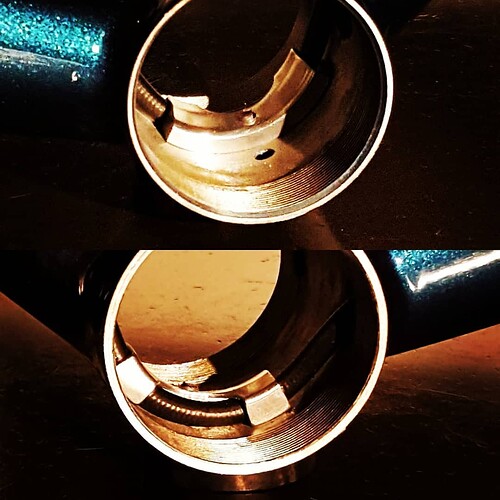

My approach has evolved a little over time but one thing I have always done is reinfroce the penetration in the main tube. I choose to do it internally as opposed to an external plate. There are pro’s and con’s to either but I prefer the cleaner look the internal plate gives.

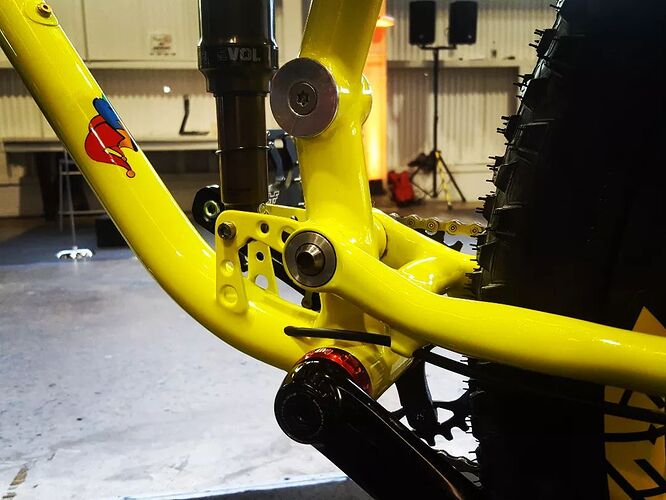

Below I have photos of a DT rear brake run. Enters drive side top of DT and exits NDS bottom of DT. Wraps under BB and along underside of CS.

I use the same method for road rim brake lines. Just adds to the ultra clean lines you can get and is easier to run than interupted housing and cable stops.

I’ve done a few bikes, mostly road where I run the hose through the chainstay via a T47 BB shell and a brass guide tube. These are quite fiddly and only do that if the customers wants complete internal.

The mtbs, so far I’ve done a mix. All have been DT internal with the first bike being through the CS and the rest being along the underside of the CS. I will stick with the later setup for now with full internal guides tubes.

I’ve also done a bike with full external. A little town commuter style bike.

Great work and great photos!

Can you share your process to do this?? It looks like you apply the heat from the outside and feed the silver from the inside. I’m guessing the hole is just to help locate it?

No i feed the silver in through the hole and draw it to the edge with heat applied to the outside. That way I know I get a ful wet out of silver under the plate.

This is incredibly well done, as always. Thanks for sharing!

Internal through the DT and then external along the CS seems like a great solution.

Started a new frame today. It’s going to get a dropper post, how big /what size needs the port to be?

Thank you

I am going to build my next frame with internal through the headset.

Partially for the super clean look

Partially for no need to drill holes in a critical spot on the down tube.

Partially just to give it a go.

Partially to piss off a couple friends that I know it will irk.

I’ll do an EC44 top cup and custom turn a nice clean top cap with the holes where I need them.

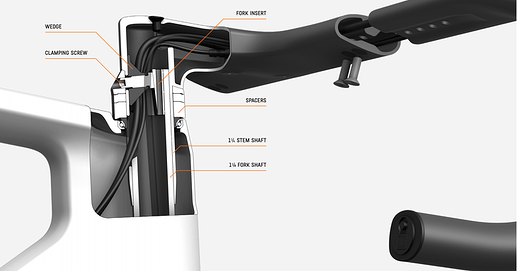

I personally don’t mind internally routed cables through the headset. But I do have concerns about how big companies implement it:

- I bet 90% of riders won’t swap the stem or bars for fit (road/gravel bikes)

- I think they are rushed to market

- there are so many cases of recalled forks

- I think there is a ticking timebomb with cable rub eating away the steerers

- Crashing the bike can result in ripping up your cables

I know a few off-the-shelf systems:

FSA ACR:

Weird IS standards

EC44 has anyone tried this?

King Aeroset 3:

EC44 standard

First:

IS, EC, ZS options, but nothing for 44mm headtubes

English has a couple build examples using the FSA EC44 headset.

@earle.b Haha, I love the drivers for this.

Do you want me to send you the bar stem combo to go with the cable routed headset? That would get a rise out of your friends too!

Btw, I would go bigger than a 44 in order to avoid cable rub on the steerer tube.

I do love the look of those bar stem combo, but I run a bar with 15 degree backsweep.

I don’t think the 44 makes a difference, as you still need to feed the cables into a 38mm downtube so that will be what forces the housing close to the steer.

I’ve done one frame for the FSA ACR system, but with a custom 3D printed top cover (and a heavily modified RS1) Had a stainless steel headtube made with the brake hose sticking through from the downtube. Was pretty easy to work with, but I do feel the headtube gets a bit too chunky for a slender steel frame. Luckily this was for a SRAM employee that had to test the Rival AXS before it came out, so I just had to do one internal line.

On the subject of cableguiding: I used to prefer external, but I find myself loving internal more lately. For external I always route cables on top of the downtube and chainstays, for internal I use brass or stainless tubes all the way, and build a nice fillet with silver. I do however route the cable under the BB on HT’s and then into the chainstays again, as I don’t like to fiddle in the BB shell. (yet…)

That looks really nice! Did you drill through the steerer for the front brake and did you end up reinforcing the hole some how?

![]() i worked at a bianchi / factor / colnago / cervelo shop until last year and throughout the intro of this on most models.

i worked at a bianchi / factor / colnago / cervelo shop until last year and throughout the intro of this on most models.

i think for people like us in the custom world its not a huge issue. we know (as much as one can) what bar, stem, headset spacer and hood roll our customers will want.

that being said, in the retail space it is an incredible pain in the ass. a lot of these bikes are moving towards 1-piece bar stems as well, which adds to the chaos.

- want a different bar width or stem length? new bar and stem coming from italy, and we’ll have to re-route and re-hose (usually new hoses) the entire bike.

- build a bike for the floor, throw 30mm of spacers under the stem to be safe. customer buys it, wants/needs to slam the front end and you’ve got to hope you can find space somewhere in the frame for the hose to sit without it kinking (or rattling).

rant aside about the retail side of things, i think in the custom world it can be something really cool.

To continue the rant, I had a friend who had to wait several months for the new canyon ultimate, only to return it because the custom bar stem quill system only allows 15mm of spacer adjustment! I think that’s literally crazy. You can’t even test-ride a Canyon. I understand it’s a race bike but some people just have longer legs and shorter torsos.

its insane.

we sold a $16,000 cad Bianchi only to have it sit around for months waiting on a different bar/stem combo.

its been happening in the tt/tri world for a lot longer (y’all every try and replace trek tt bike headset bearings?), but that was more understandable as it was a small market with very specific needs.

Yeah, modular/replaceable and adjustable are all features, not bugs, IMO. But counting grams is a popular pursuit and you’ve also gotta differentiate your new bikes from your old ones visually to keep those $16k customers coming back.

I guess what I’m saying is…don’t hate the player, hate the game.

-Walt