Alright look - as long as we all agree not to use something that’s basically a skate bearing for the headset upper then I think we’re pretty much good otherwise. ![]()

in this essay i will be arguing the validity of a 14mm id headset bearing…

Luckily the guy I was building the frame for modified the fork, but he did drill through the steerer and reinforced everything with extra carbon if I remember correctly.

I think I’d still be a bike mechanic if high-end bikes hadn’t all become awful to work on in the past decade.

Is 5/16” tubing what’s normally used for running jnternal brake lines? I have someone who wants me to remove cable guides and run a tube through his top tube for full housing. I found 304 stainless 5/16” brake line for a good price, just wondering what other people use as far as tubing diameter. Does anyone know what size tubing these housing guides are made for? I’m hoping they fit over the 5/16 for reinforcement.

I usually use the Silva stuff from Ceeway in England. (Being in Atlantic Canada, I have to pay international shipping for everything, and I’m closer to England than Seattle lol.). But their pricing is excellent, far less than the US distributors.

Mark Beaver

Tamarack Cycles

I’ve used 1/4x.02 wall stainless tubing from McMaster. It’s a nice fit for 5mm brake housing.

Before cutting into the frame make sure you can fish a tube through on a practice tube. I’ve always installed them before brazing the frame together by inserting the pre bent tube through the open end of the tube, popping it through the first hole, and then popping it through the second hole. Doing it to a completed frame might be extra challenging or impossible.

An alternative is to use the Cinelli guides sold by Metal Guru. That’s what I would use for your project.

Thanks for the advice, I do plan to do a practice run before cutting into the complete frame. Also found some 1/4” x .02 tube, I was thinking the 5/16 looked a little big for a 1” top tube.

does anyone know what’s happening inside the “new” 3t Strada headtube?

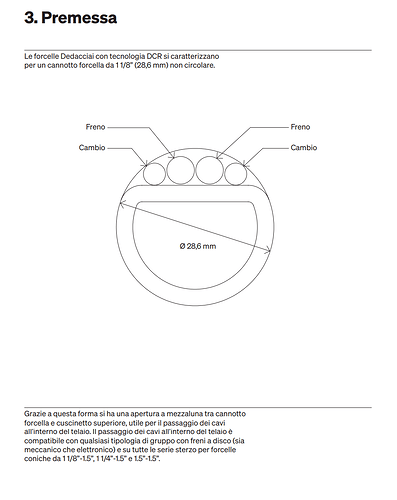

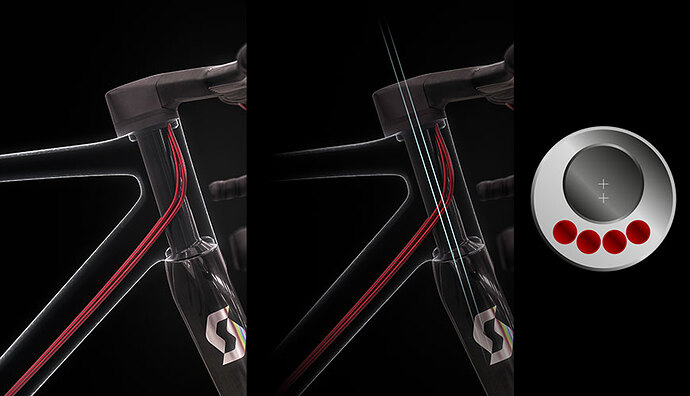

from what I can gather its got to be a 44OD/35ID upper bearing with; an eccentric lower bearing seat, an eccentric hole in the upper bearing preload wedge, a la, 2023 Scott foil RC, and thus effectively an eccentric steerer ( the steerer isn’t centred on the steering axis)

this puts the steerer basically hard up against the “back” of the upperbearing, keeps the width of top of the headtube from getting ‘too big’, and leaves a theoretical (35-28.6=) 6.4mm gap infront of the steerer where the hoses and wires can squeeze through.

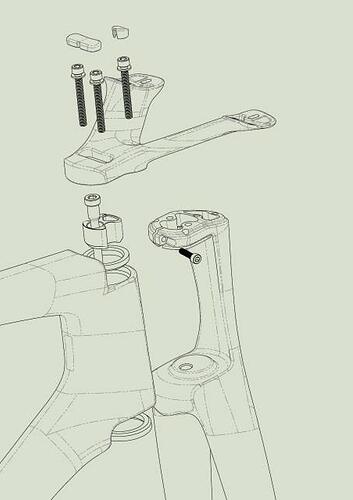

Im interested, because I /think/ im building a disc road bike ( my first, after ~50 odd frames) and doing some pretty serious thinking about putting the cables inside. keeping the diameter down is high on my agenda; I’m a “weld IS cups onto the headtube” guy.

I have been doing full internal for about seven years now. Hydraulic brake lines don’t mind tight bends, neither does electronic shifting. I have done a few with mechanical shifting too, after riding a fully internal Ekar for 10.000km myself and after telling customers that the obligatory changing of shifting housing is a pain in the ass.

The only problem I see is that the client needs to know about his or her body contact points. Experimental finding of the position on the bike is a pain in the ass for obvious reasons. Since pretty much all of my clients have a long standing background in cycling that’s not a huge problem.

Do you have a picture of this? I was unable to find any info. Is it similar to Deda’s D shaped steerers?

I don’t /know/ about the 3t, doesn’t seem to be any consistent info on it yet. Im waiting for someone to publish a build video or similar.

The Scott system looks like this; Round steerer (which is more interesting to me, because I dont like the look of that deda fork)

It’s possible there’s a version of the 2023 cervelo s5 that’s also got a eccentric situation inbetween the bearings, though I wouldn’t call it a steerer…

I’ve only seen this one illustration though.

Do you guys use brass tubing or stainless to route the cables internally?

I just did my first try with brass 0,5mm wall thickness tubing and the obvious happened. ( it wasn’t so obvious before it happened lol)

What do you guys recommend in this case?

Drill it out or heat it and pull it out, clean it up and then use silver solder to put in either a stainless or brass tube. I have been using both so far without issues. But even with silver heat control is important, I have managed to melt a brass tube like that in the past.

Do you need a translator?

Today i did something stupid. I planed the bike with flat mount, front derailleur and rear derailleur.

I brazed these nice stopper from PMW on the dt. Than i realized, there is no place anymore for the breakecable… I don’t want to cross the shifting cable with the breakingcable… so my question is:

- Do you know some other nice housing for the breaking calbe or places for the cable guide?

- Can i add a internal cable routing after? like Fern does it? The plan is to leaf the DT at the top of the bb. so i can place the cable on the top of the chainstay.

so green is outside the tube and blue inside.

You’ll be able to get it in teh DT. Youll just need to cut your slots carefully and shape the guide tub to suit. Buy some extra tube incase you stuff up the first one. Don’t forget a reinforcing plate and use silver the keep teh heat down.

Maybe I am missing something, but what is wrong with crossing the brake hose over the shift cable? You can do it at BB. No one will see it because it is behind the chainrings.

Another less risky option would be to drill a few more bosses for paragon clips. They are really low profile and hold the hose ontop of the tube. Zip ties end up wavy with a gap.

https://www.paragonmachineworks.com/cable-stops-guides/aluminum-single-cable-clamp-choose-style.html

If you choose a dark paint scheme, you won’t see the clips or the hose.