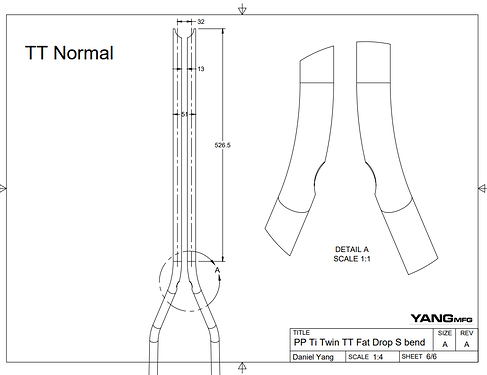

Every few months Whit @Meriwether Cycles hits me up for help on a cool project. In this case… A titanium, fat bike, drop bar, twin tube, klunker, with sliding dropouts. This bike wins the custom framebuilding bingo card.

This is the first time I have seen CAD being used to sequence the compound bends to achieve the twin top tube + s bend stays.

Why this was so challenging:

- all 3 bends must be done in one shot

- Tire clearance for fat bike tires

- Cobra bender is limited to 36deg w/ 19mm titanium

- Bends must have enough overlap at the seat tube miter

- Left and right stays must be exactly same (done in tandem)

- titanium means expensive mistakes

Process

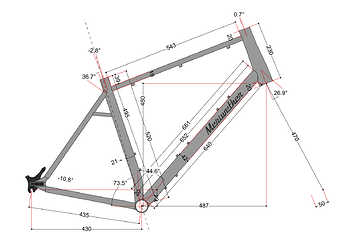

Whit sent me bikeCAD which I converted 3D in order map out the bends and tire clearances :

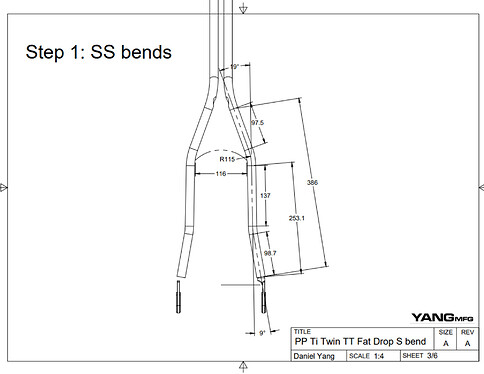

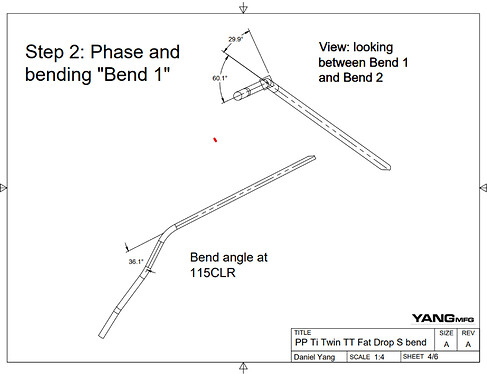

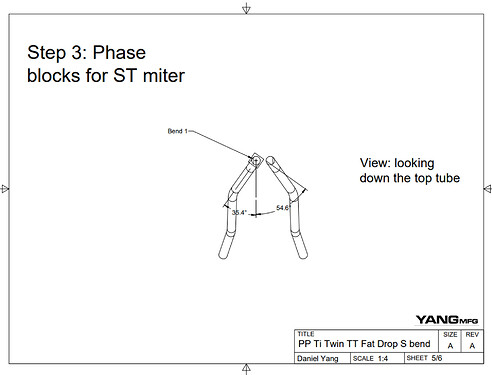

From there, I created the sequences of 2D drawings which show the:

- bend location

- bend angle

- phasing angle

Thanks to the CAD, I knew it was physically possible, but we still had a three-hour call to figure out how to do the bend sequence in real life ![]() . Whit caught a pretty big issue: due to springback, the Cobra bender maxes out at 36deg w/ 19mm titanium tubing. The first draft had the SS-TT bend at 37degs! We ended up massaging the geometry and bends to bring it to 36deg.

. Whit caught a pretty big issue: due to springback, the Cobra bender maxes out at 36deg w/ 19mm titanium tubing. The first draft had the SS-TT bend at 37degs! We ended up massaging the geometry and bends to bring it to 36deg.

The results

This is all Whit’s work, so make sure to give him some kudos. I am always impressed by his level of fabrication skill.

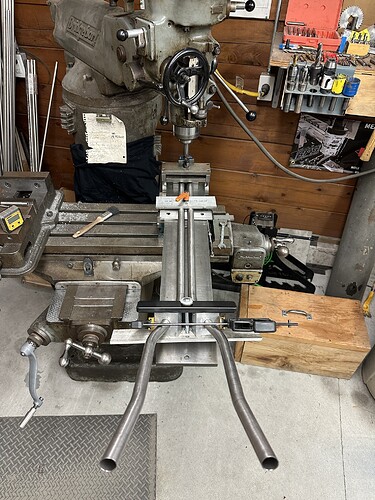

Bending and Mitering

Final Results:

I’m really happy about how this one came out!