From memory it was the shifting quality. A slight hesitancy which when they got the new hanger in seemed to have corrected it. Having said that I’ve used the SRAM hanger on a few road and gravel bikes now and had zero issues with getting great shifting. Not sure if its a UDH related issue or something else on that particular bike.

Ah ok. Shifting is always spot on these “hanging” sram derailleurs, so thats not the issue. Let’s hope Sram fixes this “issue” with the new road groups.

@project12 , @JMY , I talked to Sram about it when we decided to include UDH on our road bike and gravel bike a few years ago. The word they gave was

Using a UDH hanger with a road derailleur puts the derailleur outside the adjustment range of the b limit screw if you don’t use a wide range cassette. It’ll technically still shift to the correct positions, but your pulley cage will be a bit further from the cassette than is optimal. Our road bikes use a modified version of the UDH hanger to account for this. But, it’s only really an issue if your using a cassette smaller than 36t.

I’m sure that when SRAM comes out with a more road oriented direct mount derailleur, they’ll very explicitly state what cassettes it is compatible with.

That’s more info than I was able to get out of them.

I assumed it was going to be something along those lines. .

I have to question the cassette being the limiting factor though. A 10-36t cassette obviuosly encompasses the same range as a 10-28t or 10-33t, so why would running a cassette with a smaller max tooth count affect anything?

My interpretation is that this applies when using the “max 33t” derailleurs and not when using a max 36t deraillur with a smaller cassette. This lines up with my experience since we’ve had no issues running a standard UDH hanger with a 2x road setup using a Force RD (max 36t) and a 10-36 or smaller cassette.

It’s not so much the range but how close the upper pulley wheel sits to each sprocket on the cassette. The further away the upper pulley wheel means it is slower and less ‘precise’ when shifting as the chain has more length between pulley and sprocket to take up the clearance between the plates. The closer it is the more direct the control is, but too close and it clashes too much with the bigger sprocket as it moves sideways.

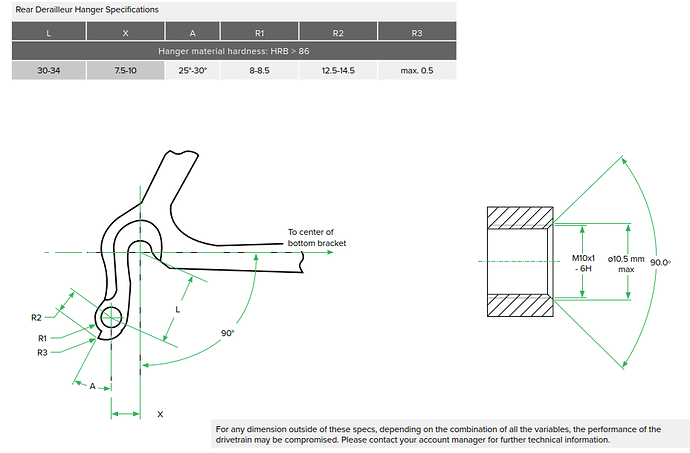

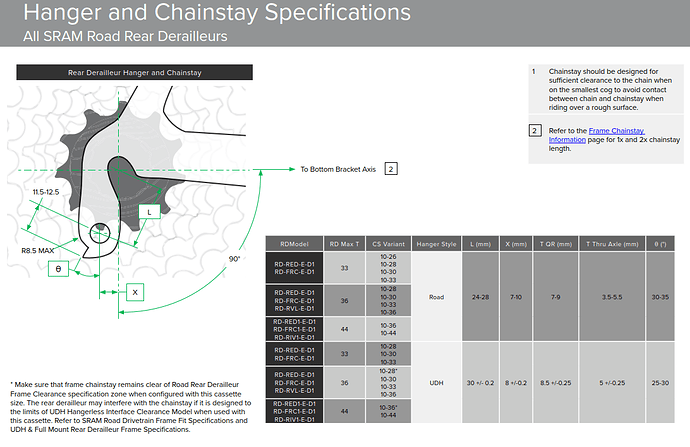

Below is the 2021 MTB spec and then the 2023 road spec from SRAM

The bike above has a 33t cassette and shifts fine, but I have to admit I hadn’t thought about there being a limit with a UDh hanger. Good to know if someone orders a true roadbike.

What I meant by “range” is that a 10-36 cassette will include a cog thats within the cog size range of the smaller cassettes. I.e a 10-28 cassette will simply be equal to running a 10-36 shifted to the 3rd largest cog.

As such, a smaller cassette can not possibly be the limiting factor.

It has to be the derailleur’s max capacity that dictates how well it performs depending on the hanger.

New Red groupset dropping next week. Verrrrrrry expensive from my source.

Throw all the stuff inside away and fill it with beer and ice. Then ride your oldest bike down to the creek and drink in the shade.

^Follow this advice

Changing topics a bit - has anyone else had issues with axles getting seized in UDH dropouts? I was working on a wheel in my shop and had to take it out of the frame, but after reinstalling it I wasn’t able to unscrew the thru axle from the dropout. I ended up having to hacksaw out the UDH as the threads had totally bound to the axle.

The axle threads were greased relatively recently and I didn’t brute force the torque or cross-thread the axle so I’m wondering why this happened. I admittedly was using a weight weenie axle and an aftermarket (Wheels Mfg) hanger so that could be the issue, but I’m wondering if this is a more general trend.

I’m curious if the M12 x 1mm threads lend themselves to being more sensitive to galling compared to the more traditional 1.5mm thread pitch. There’s ~9mm of thread engagement on a UDH hanger which is similar in width to most PMW dropout inserts so that’s 9 threads engaged vs 6 on a coarser pitch.

Was either the hanger thread or skewer bare aluminum? Aluminum has a tendency to gall with bare aluminum contact. Anodizing will reduce this tendency, because of how hard anodizing is. In my experience, it’s sound practice to avoid bare aluminum fasteners. If you must use bare aluminum, grease will help, but anti-seize is better.

I hear where you’re coming from but I think it’s important to consider that Sram set the UDH parameters for many potential future variations of the rear derailleur. The current crop of Transmission RD don’t come anywhere near the forward stop on either side. Take a look at the video below that shows just how far back derailleur is pulled from the stop. To my knowledge Sram recommends the same chain length for all of the transmission rear derailleurs so you shouldn’t have any issues there.

It is super frustrating that the main two design attributes that make metal dropout designs difficult are not actually needed for the current generation of transmission rear derailleurs. (cable fin clearance/stops and forward rotation clearance/stops) You could make a really small clean sexy dropout that ignores these so it’s only compatible with current transmission rear derailleurs but it’s entirely possible the next gen derailleur will actually use those clearances and your design won’t be compatible. It’s also entirely possible that they’ll never take up those unused clearances.

I tried to advocate for a TDH (transmission derailleur hanger) that was designed specifically for this crop of derailleurs and I still think the concept has legs. If the next gen derailleurs don’t fit then the frame will still have a standard derailleur mount. However, keep in mind Shimano, TRP and likely others are currently designing rear derailleurs that fit within UDH spec and may fall in some of those unused clearances.

I’m going to the launch event here in Melbourne.

We’ve also got a bike with the new groupset sitting in the workstand at the moment. ![]()

I’m liking it.

Hey. I’m new to bike building so just have a question regarding UDH.

If I am designing a mid high pivot with a chain idler the documents say to angle the clearance model upwards so that the chain from hub to idler is inline with the model. Does this also mean that the fin (cylinder to stop rotation) will also need to be rotated with changing the angle of UDH?

Thanks.

@TBui You are right; the SRAM documentation is ambiguous; they only say to rotate the clearance model for idler pullies.

However I think its a safe assumption is that you are rotating the clearance AND the hanger (and T-type interface). The clearance body represents elements of the derailleur, so it makes sense that everything is rotated together. Logically, it also follows that the whole package needs to be rotated upwards to match the chain wrap of an idler pulley.

I totally get the upsides to UDH and the related Transmission group sets for MTB, the burly hanger Interface blah blah.

But for road and gravel it all just looks so unnecessary. To my eyes, it’s a bit bulky and ugly, especially on thin and dainte metal bikes.

Makes me want a gravel bike with the Nivex derailleur

Its not made for thin metal frames. Its designed for the benefit of mass produced carbon frames.