Perhaps the concern is that water might collect at the inside corners of the joint that sit lower than a centered hole? Idk, just playing devils advocate…

It probably will. A big old squirt of ‘framesaver’ should fill them same corners. This has been my go to for a few years now. One can will do about a dozen frames.

Water will still get in past the seatpost. Through winter I get in the habit of of removing my seatpost and tipping the bike upside down every month or so just to check it’s not accumulating. I know some people who used to remove their seatpost after every wet ride to let things air out but with a dropper post that’s a bit of a pain.

Also, I know of at least two builders who often don’t put any vent holes on their bikes, and I have a couple bikes built like this. One is this exact frameset built with relatively light tubing (.8/.5/.8) and has over 35,000 km without issue.

Most tubes are sealed, the ones which are open get treated with framesaver.

Would their be a specific TIG sequence that allows you to seal up the tubes with the final pass. Anyone else aware of such a process?

Any size of vent hole is still going to allow some moisture to remain once it gets in, though. So there’s no point in panicking about it. Shoot in a little framesaver and maybe pull the seatpost occasionally and you’re good.

Modern cromoly doesn’t rust very fast regardless. You have to really, really try to actually damage a frame.

-Walt

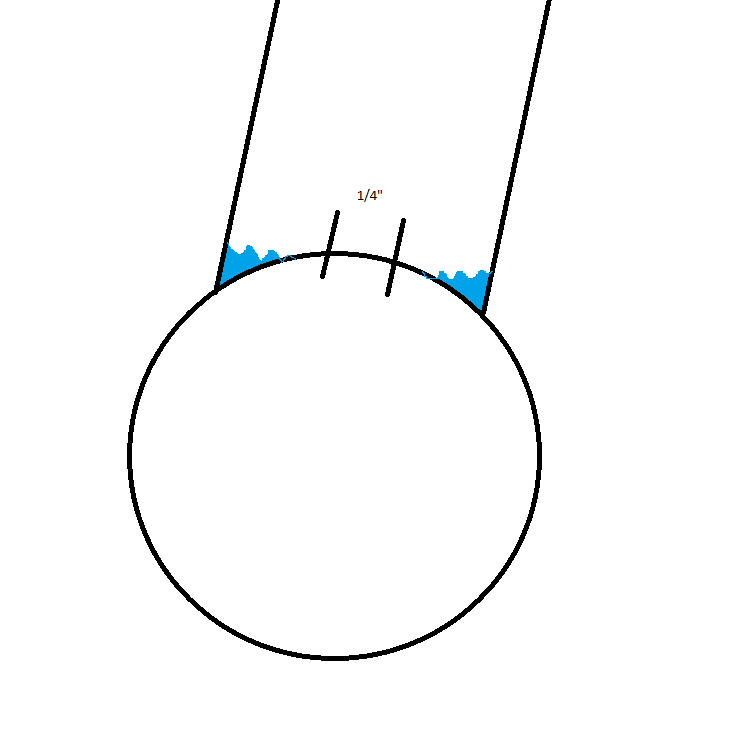

I like to drill two 1/4" holes in the BB shell nearer the low spots where the ST meets the shell instead of a single hole in the center. Not sure if it’s better that way but I figure it’ll allow more water to travel to the BB shell.

excellent visual, yes that is what I have been fretting about ![]()

I’m liking @manzanitacycles’ two low spot holes and that amsoil stuff looks real nice @bushtrucker. @anon91558591 you’re right it really doesn’t rust that easily!

if you are welding and not purging why drill vent holes?

Sometimes the heat causes pressure in the tube and as you are about to seal it up it spits a nice little glob of metal on to your tungsten

that can be dealt with thru practice , patience and weld sequence.

Thanks for thinking of me bud.

I see a few frames for repair every year that have a completely rusted through seattube at the bottom bracket shell joint, they are without fail missing a drainage hole, or have a tiny vent hole plugged with grease and debris, often with the blind water bottle bosses that were supposed to keep water out. I also see a few rusted through top tubes every year, usually older stuff (like 20 years old) and these are usually top tubes with only one vent hole. I see frames with bigger vent holes (within reason) have rust issues less often, seems to equal more airflow and less holding capacity inside the tube below the lowest edge of the vent hole.