Hi,

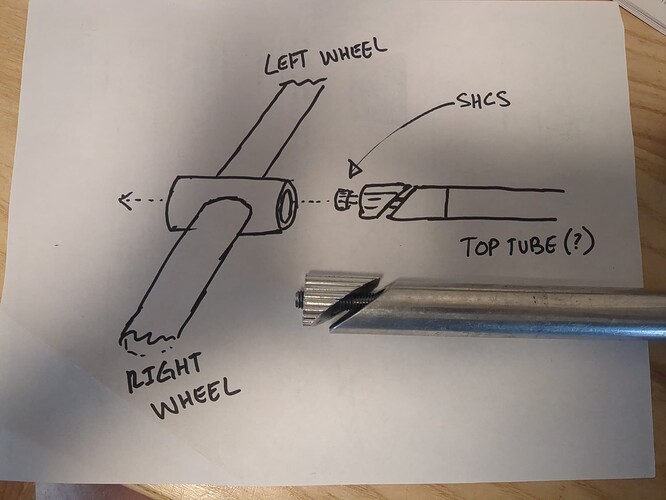

I was asked to build a larger version of a walking aid bike-like thing for a kid. And I’m looking for some inspiration - I’d like to make it so the the marked bit can be disassembled and looking for some inspiration. Maybe some of you have any ideas how to join these tubes in a smart way?

im imagining an extra sturdy version of a stem/handlebar/faceplate arrangement there, which bolts up for assembly, maybe with a couple QR levers for tool free assembly?

im guessing you’ll need a mechanical provision to ensure it doesn’t slip rotationally, as the “raised axle” arrangement lets bumps in the road (or weight on the saddle) generate torque about that lateral bar, but I imagine its necessary for heel clearance while walking.

Your description exactly matches what I was thinking about, and I tthought maybe there’s a smart solution (and easy to machine) for these constraints

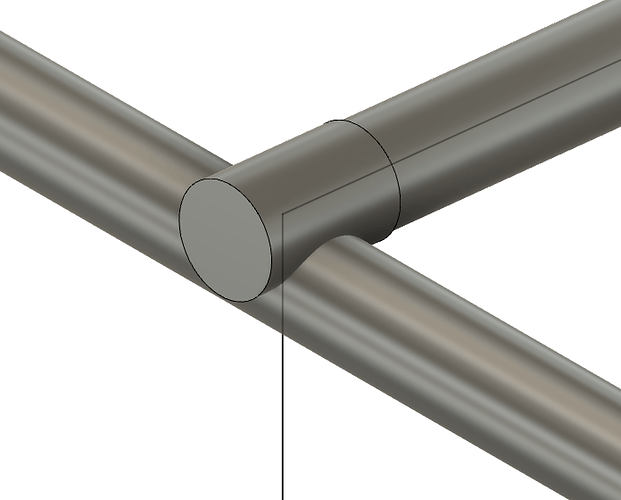

This was a quick thought I had. Maybe you could take inspiration from a stem? A receiving sleeve could be welded into the rear wheel assembly and an interfering wedge to the mating (top?? don’t know what to call it) tube on the front end.

I bet it wouldn’t be too hard to incorporate a clocking feature in there as well.

A first pass at the idea but I’m going to keep thinking on it. What a fun challenge!

If you need them to be removable or adjustable, why not use an ultrashort stem? Nowadays there are even in-line stems, you could then make some shims if the diameters don’t fit 100%

edit: sorry just read that is what you were looking at ![]()

+1 for using one S&S coupler.

a thought about this came to me out of the blue today.

must it join/split where you’ve initially noted?

what if the trike was made from a front assembly that finished in a seat post/seat tube, and a rear assembly that clamped onto that seat tube or seat post. it moves the joint away from the position where weight of the user is trying to slip the clamp rotationally, its an area where getting telescoping tubing to make slip/clamp fits is esapblished, and it might actually allow you more adjustability long term? by moving the rear assembly up and down the seat tube.