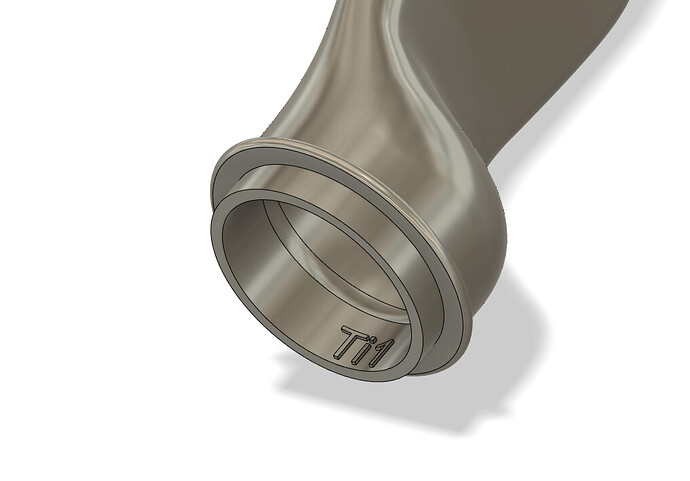

The little fusion rings help out a lot for welding. I have been playing around with the best dimensions. It’s a bit tricky because those fusion rings are often printed as unsupported overhang. This leaves a “broken edge”. Which is fine because it gets melted. But in general, its best practice to minimize print defects because they could have an impact on the mechanical properties.

So far for the CS yoke, we are at a 1mm thick lip that sticks out 1.3mm

I think it could be a bit bigger, but as I said, I don’t want to put too much material on an unsupported overhang.