As a lone worker a bit out of touch with the world, I only recently happened to come across this new legislation GPSR (General Product Safety Regulation) that will come into effect by 13th Dec.

What does it mean for us the small framebuilders? Will it be so much harder to export to the EU? Does anyone have any knowledge???

The way I see it: It doesn’t change anything, since bicycles and bike frames are already well regulated in the EU. At least that was what I have been told at my local chamber of commerce here in Austria/EU.

So in essence, if you were to sell a frame to someone in the EU, you have to make sure it complies with the product safety regulations for bike frames over here. To satisfy this requirement, you’d have to pass all sorts of DIN/EN/ISO tests and stick to good engineering practices while designing it, label the product, document the manufacturing process, have a serial number… This is alredy the case today, before GPSR. Nobody in our little frame building world does that, nobody has ever done it and nobody will. When something goes wrong, it probably falls back to your product liability insurance policy what exactly happens.

This whole thing is mainly aimed at “new technology” items, which -because of their novel nature- were not really regulated before.

For manufacture and sales within the EU, it will make almost no difference. The normal CE/ISO compliance, with some exemptions for custom products, backed up by insurance.

However, aside from the usual safety and contact detail requirements, for those of us outside EU, there is also a requirement to have an Appointed Representative within the EU, which is a total unknown at the moment.

I suspect agencies will spring up soon offering a proxy service for a fee.

Here is a good summary blog from a UK craft/art selling platform, Folksy:

@Brelis_Cycles Burcak, from Turkey the requirements are probably very similar to me from the UK, without our local Northern Ireland complications.

All the best,

Dan Chambers

Hmm interesting, didn’t think about that AR topic. Would be interesting how the larger scale operations are dealing with this ( @Coco_PMW , @adamsklar , @Neuhaus_Metalworks , @BikeFabSupply… amongst others)

After some initial research, it seems like the AR doesn’t really need any qualification or certification other than being formally appointed by the out-of-EU manufacturer, and has no real responsibility other than properly documenting everything.

So maybe I can be your representative? Let me dive into that a bit further before inquiring though ![]()

I’m not a commercial frame builder so my interest is more as a consumer and I have seen notices by various artisans about their inability to sell to the EU after December 13th this year, due to GPSR.

As I read this discussion, a thought occurred to me; @Dan_Chambers mentioned the insurance backup. Surely, insurance companies will mandate the various certifications before they will give liability coverage? Either way, it seems that it will come back to the product producer to make sure that GPSR requirements are met.

Another good summary of the Authorised Representative requirement:

And their list of Authorised Representative companies/agencies:

Cost seems to range around €1200-2500 per year for up to 10-20 or so products. Fine for a big manufacturer with multiple products, but out of the question for any small or one-off sale. I would hope this will come down with more small service providers entering the market as the legislation kicks in and demand increases.

All the best,

Dan Chambers

I looked up several guidelines and requirements. We mainly make commercial non-consumer bike components in the US and to export to the EU. Each of our products have a description (name, part number, material used, and use description). If any purchaser needs to see the material certifications, we will send it to them. When you purchase from us, we provide our name, address, and email.

I’m not an trade expert but only a gal whose job is to put metal into boxes.

Our sales to EU are very very low, maybe 3 over 4 years. If business grows to a point where we would need an AR then it also likely makes sense to bring on an EU distributor at which point that person (or company) assumes the role of importer and AR.

This could have interesting impacts. Sorry for the infodump but I think this is all valuable information for business owners.

Here in the states, the governing bicycle standard is 16 CFR Part 1512. This standard explicitly carves out an exception for custom framebuilders

§ 1512.1 Scope.

This part sets forth the requirements for a bicycle as defined in § 1512.2(a)

(except a bicycle that is a ‘‘track bicycle’’ or a ‘‘one-of-a-kind bicycle’’ as defined in § 1512.2 (d) and (e)) which is not a banned article under § 1500.18(a)(12) of this chapter.

The governing rules in the EU (And the UK, they just call it UKCA instead), EN ISO4210 does NOT include any verbiage outlining any exceptions at all:

1 Scope

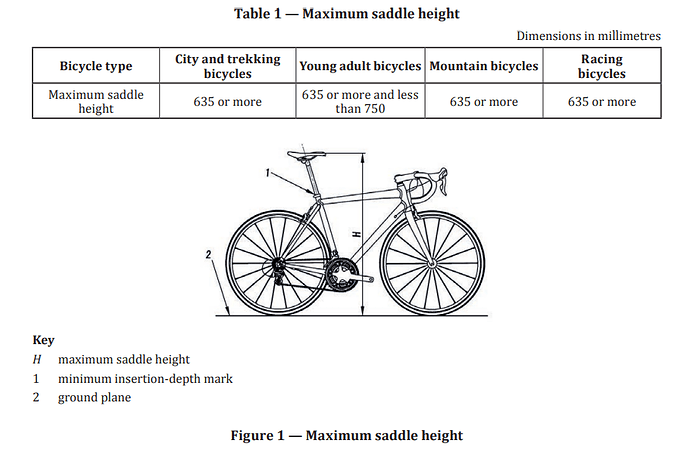

This part of ISO 4210 specifies safety and performance requirements for the design, assembly, and testing of bicycles and sub-assemblies having saddle height as given in Table 1, and lays down guidelines for manufacturer’s instructions on the use and care of such bicycles.

This part of ISO 4210 applies to young adult bicycles with maximum saddle height of 635 mm or more and less than 750 mm, city and trekking bicycles, mountain bicycles, and racing bicycles that have a maximum saddle height of 635 mm or more including folding bicycles (see Table 1 and Figure 1).

This part of ISO 4210 does not apply to specialized types of bicycle, such as delivery bicycles, recumbent bicycles, tandems, BMX bicycles, and bicycles designed and equipped for use in severe applications such as sanctioned competition events, stunting, or aerobatic manoeuvres.

NOTE For bicycles with a maximum saddle height of 435 mm or less, see ISO 8124-1, and with a maximum saddle height of more than 435 mm and less than 635 mm, see ISO 8098.

I have always been curious about how custom bicycles are treated in the EU. It’s safe to assume that anyone exporting products from Asia will have gone through CE certification which includes testing to ISO4210 and REACH (chemical testing). Luckily, suppliers will often perform their own chemical testing and you can get a letter of conformance so you don’t have to double up on testing.

The ISO4210 testing needs to be done on a representative frame sample, I have quoted it at about $3000 each a few years ago with the US based ACT labs.

Most of these standards do allow for self certification, this is what most of the larger companies do.

Self-Certification

- Possible for In-House Testing: Many manufacturers perform testing in-house if they have the facilities and expertise to follow the ISO 4210 procedures accurately.

- Documentation: Proper documentation and traceability are essential to demonstrate compliance, especially if a regulatory body or customer requests proof.

My understanding of the GPSR after a little chat with my friend GPT is that it only applies if there is not another standard to apply, such as the toy safety directive or EN ISO4210 bicycle standard.

I interpret this as saying customs is going to start cracking down on imports and ensuring they are CE compliant. Frame builders do not have to worry about GPSR because their products are already defined under EN ISO4210. Frame builders whose products are not covered under EN ISO4210 should probably start the process of self certification.

A large part of CE compliance the “Declaration of Conformity” this is a document controlled by the importer Showing the following information:

Key Components of the Declaration of Conformity (DoC):

- Title:

- “EU Declaration of Conformity”

- Manufacturer’s Information:

- Name, address, and contact details of the manufacturer (or the authorized representative if applicable).

- Product Identification:

- Clear identification of the product, including:

- Product name.

- Model/type number.

- Serial numbers (if applicable).

- Applicable Directives:

- List of EU directives under which the product is being declared compliant, such as:

- General Product Safety Directive (GPSD).

- Machinery Directive (if applicable, e.g., for electrically assisted bicycles).

- Other relevant directives like REACH (for material safety) or RoHS (if electrical components are included).

- Applicable Standards:

- The harmonized standards used to demonstrate compliance, for example:

- EN ISO 4210 for bicycles.

- EN 15194 for electrically assisted bicycles (if applicable).

- Statement of Compliance:

- A statement declaring that the product complies with the essential requirements of the listed directives.

- Test References:

- Details of any tests conducted to demonstrate compliance, including references to accredited laboratories (if testing was outsourced).

- Manufacturer’s Responsibility:

- A declaration that the manufacturer is solely responsible for ensuring compliance.

- Signature and Date:

- The name, position, and signature of the authorized person within the company.

- The date of issue of the declaration.

- Optional Information:

- A reference to the technical documentation maintained by the manufacturer.

- A list of additional applicable standards or test methods used.

If you are already exporting frames to the EU without a DOC then it may be fine, but there is a chance they will start asking for these documents.

The standard also covers frame and packaging markings and user manual requirements. They are all quite simple things that frame builders can handle.

I would suggest reaching out to a smaller test lab such as this About - Bike Testing

and have the same conversation. Their test prices seem very reasonable and I think testing one representative frame sample would be enough of a CYA for independent frame builders.

Obviously, I am not a lawyer but I did this kind of work for Strider bikes for several years so I’m quite confident in my interpretations of the standards. Feel free to reach out with any specific questions.

The crappy part about this kind of stuff is that no one can really tell you for certain, even the test labs. Think of it like insurance, it’s there for if the worst case happens.

I’m the last guy to suggest standards don’t matter, but I have to agree with the above snipped words. Framebuilding (as carried out by independent framebuilders as opposed to, say - production shops) is considered an outlier task compared with the larger bicycle trade. Everything (we do) is essentially one of a kind. I remember long ago when the CPSC’s reach spilled over into our industry. The regs then were conceived and written for the Schwinns and Cannondales of the world. By extension, it’s also similar to the confusion that surrounded the initial foray into frame labels brought when the UCI tried to describe what a bicycle is by using frame design and rider positioning. People who made frames full time were considered differently and grouped as a sidebar.

Again, if you’re not adept, or if you participate in the trade and don’t carry liability insurance, then 1) get skilled first and, 2) don’t (never) put anything into the marketplace or mainstream until you’re fully covered.

ISO tests in Portugal are much cheaper than that in ABIMOTA. If anyone needs help let me know.