Intro [WIP]

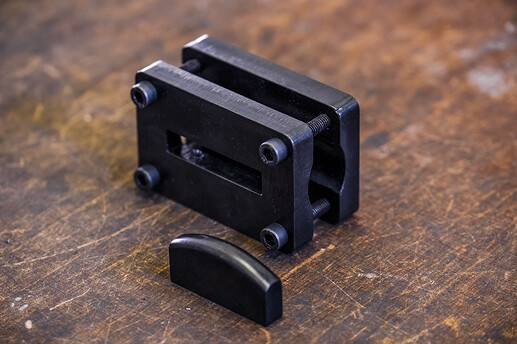

Vogeltanz Fixture:

This fixture is designed by Josef Vogeltanz (IG) It uses a urethane support block and cylindrical dies. It’s one of the nicest setups I have come across!

Key Attributes:

- Cylinder style die

- urethane support blocks

- Lead screw compression

- extremely well designed!

44 Bikes:

Chris Henry of 44 Bikes has kindly detailed his dimple setup here: Clean Procedures - 44 Bikes . He pre-bends the chainstay and uses an aluminum support block to support the tube as it is squished. The support block is “ovalized” near the bend, allowing the material to mushroom out

Key Attributes:

- pre bent tube

- aluminum support block

- Cylinder style die

Konga:

Konga has come up with an ingenious cost-effective laser cut dimple setup: IG link

Key Attributes:

- cost-effective

- laser cut design

- Only works on straight tubes

- Dent style die

ORA Engineering:

On a trip to Taiwan Spring 2024, I asked ORA how they dimple their tubes. They were kind enough to share their process:

They use one of the biggest die dimples I have seen. The shape is a hybrid of the “cylinder” dies and the “dent” dies. The chainstay is held in place with an adjustable fixture:

A key element were the pivoting blue blocks, made out of plastic. The shape of the blocks were “ovalish”. An exact match to the tube profile did not seem to be important. The pivoting allows the fixture to support different chainstay bends and “give” a tiny bit as the tube is dimpled. This prevents the tube from denting on the other side of the tube and creates a tiny bend (1-2deg?).

They told me the location of the die relative to the blue blocks was critical. There was an art to it (experience), but they try to put it on the edge of the blue block (as shown). This prevents the tube from denting on the other side.

Key Attributes:

- Massive dimple die

- Hybrid of dent and cylinder style die

- Supports pivot to allow the tube to bend

Maxway:

Maxway uses an adjustable dimple insert inside of their clamshell mold. They told me they need to adjust the die’s height to account for variations in the tube hardness. These clamshell molds cost ~$3kUSD to make when doing a production run. For a run of 250qty frames, that ends up costing $12 per frame!

Key Attributes:

- Dent style die

- Die is adjustable

- Clamshell forms the chainstay and dimple at the same time