For my 39mm BSA bracketshells I am looking for a finetoothed 39mm holesaw. I can find pretty much all other needed sizes (or so close that 2 strokes of a file make it fit) but a 39mm doesn’t seem to exist in Europe. Maybe there is a US size that comes close? I can convert, but I am having some trouble translating 1.53543 inches to a fraction

Sorry no 39mm in sight here…

Out of curiosity what BB are 39mm OD?

I mean what brand/manufacture?

The ones I get from Ceeway, but I don’t know the brand

Ceeway seems to sell a few paragon parts. These might be it if there’s a ring cut on the face of the drive side.

The ones I get are without the driveside cut, and according to the export documentation made in Taiwan.

I looked around on some hole saw manufacturer’s websites, like Milwaukee and an industrial supply company, McMaster Carr. There’s nothing in imperial that’s very close in hole saws. There seem to be 39mm annular cutters only.

1.5" would be 38.1mm and usually these hole saws wobble enough that this gets you withing one or two strokes with a file I’d reckon ![]()

Alas… Still needs more work than I’d like. Even with a large wobble. ![]()

1-1/2 is a bit too small, 1-9/16 is a bit too big. They don’t make many holesaws in /32 increments, so 1-17/32 isn’t an option.

You could slightly ovalize a 1-1/2 hole saw.

https://www.saegeblatt-shop.de/p/hm-tiefschnitt-lochsaege-39-mm-inkl-zubehoer-

These are technically core drill bits but they essentially do the same as a hole saw. You’d have to manufacture a different arbor though

@Carl_Snarl has 38 and 40

No 39

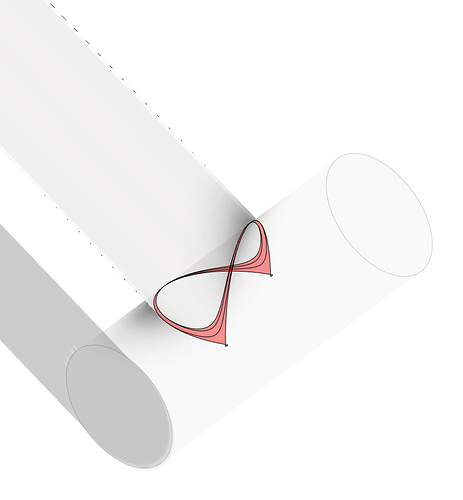

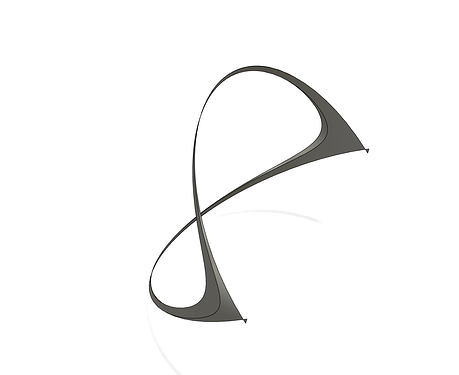

Have you tried using a 38mm hole saw? I feel like the real world 38vs39mm miter is very small:

This is the “extra material” you get with a 38mm hole saw and a 39mm BB shell:

It looks like if you rouned off the ears, the miter will be within .1mm of fitting

We regularly miter to tapered headtubes with just a hole saw miter without shaping it with a file.

Maybe a calibrated squish in the vice or a drop to the floor will do the trick ![]()

Skim a 40 mm saw on the lathe?

I tried the 38, but it really doesn’t fit the bracket straight away (even with a wobble) and you’d have to file the ears, which is more of a pain than the inside of the curve. I have also skimmed a 40mm with the belt sander (the teeth don’t play nice with the lathe ![]() ) but that dulled the saw too much.

) but that dulled the saw too much.

My current solution is indeed the core drill (but from Ali) that comes in a perfect, no filing needed, 39mm. Only downside are the big course teeth that sometimes get caught on thinwalled oddly shaped columbus tubing and f*ck up the tube… So a finer version would be perfect.

I am also talking to Silva for one of their tubecutters, but that contact is a challenge, hence I thought I’d check here first before I drive off to Milan. ![]()

Have a chat to Andy at Strawberry Cycles/Torch and File.

If you’re looking for a thicker wall than a 38.1 bb, why not order some 40mm/ 1 9/16” bsa bb shells from paragon? That way you can use a cheap hole saw that is readily available. I’d think that would be less of an expense and hassle than a custom made cutter.

Is it worth it to use these weird sized BB shells?!?

I mean, you can get 38mm, or you can get 40mm from Paragon. Then you can use an existing cutter.

Unless you have like 500 of these shells or have some specific reason for using them, I’d just stick them in a box to gather dust and get different shells.

-Walt

Weird? Maybe in the land of the free, but on this side of the Atlantic it seems that 39 is a standard size. Checked with several suplliers and builders and they all come up with the 39mm when asking for a BSA bracket shell. 38 is the light variant and 40 the heavy duty as far I have understood ever since I started building.

But my initial question has been answered; there is no 39mm holesaw, apart from core drill bits or custom saws. That’s all I wanted to know, thanks so far!

Interesting. I’ve never heard of or seen a 39mm shell. But I might have my 'Murica blinders on.

I’d still probably do something that you can get a hole saw for and call it a lesson learned.

Or get a $300 cutter, I guess. That’ll buy an awful lot of BB shells.

-Walt

This is where I email the BB supplier and ask what cutter they recommend using. I probably know the answer, I just want to make them sweat a bit ![]()