Hi everyone, I’ve been lurking around here absorbing information about framebuilding and also about 3D printed parts but I haven’t found anything about this yet so sorry if it’s been talked about but I just didn’t find it.

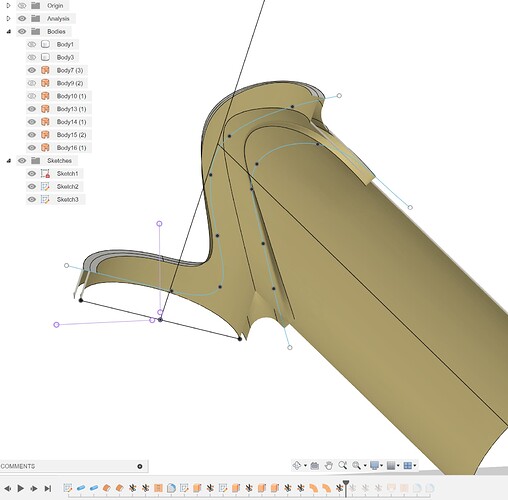

I’d love to build a modern allroad frame with classic looking lugs as my first frame and would like to print lugs for that, but I’ve been looking at some data that sort of worries me. I found that 316L has a lower rate of thermal expansion than chromoly, so wouldn’t that pose problems with the gap between the tube and the lug getting tighter as both materials heat up, making it harder for silver to flow in?

The reason I’d like to use 316L is that my first step in the direction of frame building was that I used a 316L printed custom coupler to convert my Surly Straggler daily driver to belt drive. That worked great, been using it daily for a year, worth about 3000-4000km without issues and the price of the prints was also super reasonable.

I’d use relatively big radii in the lugs to beef it up and reduce stress concentrations as much as possible.

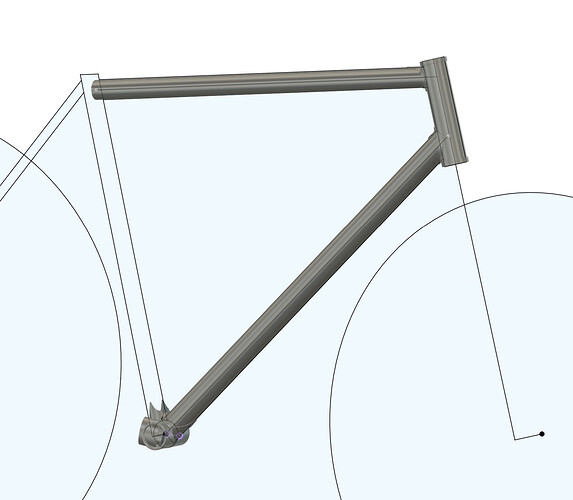

Context about what I want to build:

The bike would be an allroad bike with 35 or preferably 38mm tire clearance, 12mm TA wheels and flat mount disc brakes. I still need to see if my lbs has tools to face and chase stuff, that’s an investment I’m not ready for.

I don’t know if it’s relevant but so far I’m thinking about Zona tubing because it’s relatively affordable, easily available in Europe and seems to fit my use case. TT 28.6mm 7/5/7, DT 35mm 8/5/8, HT 36mm 1.1, ST 28.6 0.8/0.6 (not sure if that’s right for me?) SS 14mm 0.7 CS ZON114OV425.

Geo context:

Reach 395-400mm (for use with 80-90mm stem)

Stack 570-580mm

Seat tube c-t 500-520mm

STA 73.5-74 deg

CS 410-420mm

HTA 72.5-73 deg

I’m 183cm, 65kg and currently ride a Surly Straggler 700C 56cm which fits me pretty well with a 75mm stem and gravel handlebars. I created the geometry numbers and chose tubing by keeping in mind what I like from the Straggler and what I like from my 1988 hardcore Columbus SLX race bike and what I miss in both.