Thanks!

It does consist of a few parts and ideally I’d like it a bit simpler, but I think I’ve pared it down as much as possible to still work with the concept I have in mind.

I saw your first (unedited) comment and figured I’d respond to that last bit, but I have a feeling you have already figured it out. The hanger, bolt and washer are standard SRAM parts. The washers you noted are necessary to make up the thickness of the dropout - both are still needed when using a Transmission derailleur.

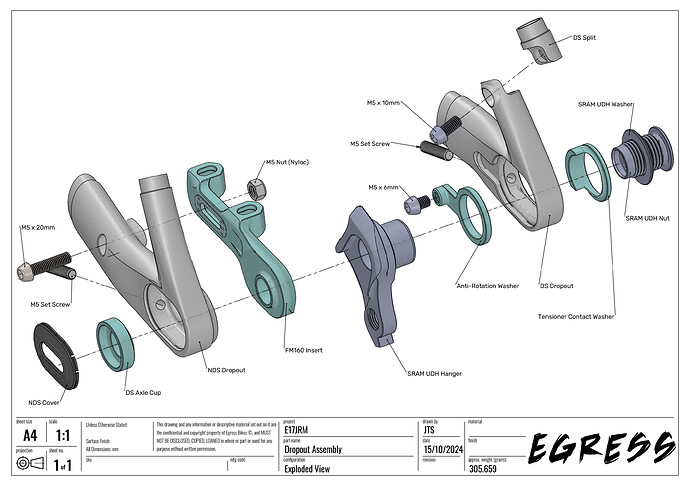

Here’s the same exploded sketch, but with a description of each part. Most of it should be self-explanatory, but I’ll add some notes below.

Left to right:

- NDS Cover - I didn’t like the big opening, so I decided I’d try to cover it with a lid

- DS Axle Cup - I don’t want the tensioner set screw to push directly onto the axle, so this cup gets to be poked instead

- Anti-Rotation Washer & M5 x 6mm - This bit moves with the hanger and provides the stop for the hanger ‘fin’. The M5 x 6 bolt is there because the full stop “nub” is not required for Transmission derailleurs. I know there’s debate about whether or not the fin on the hanger is necessary, but I’ve decided to keep it. It will act as a stop when undoing the hanger. Especially useful if I cut the hanger tang off for singlespeed use.

- Tensioner Contact Washer - This is one part I could probably eliminate by moving the tensioner contact “pad” to the anti-rotation washer, but I was unsure how well the standard SRAM hanger washer would hold up when not supported all the way around, so I added this for support.

Oh, and because I’m a geek, I also made some renderings and an animation in Keyshot.