Hey all, was checking out some steel manufacturing videos the other night and got pretty bummed/reminded the harsh impact that mining has on our environment. From mining coal, to emissions from the coking and smelting process. I know that bicycles are often touted as the greenest transportation solution, and while I don’t think any of us are oblivious to the bicycle industry’s contribution to emissions, I think it’s always healthy to examine the role (however small it may be) in that realm, and also to recognize the collective power we hold as a community to influence/pressure/encourage companies to strive for further sustainability goals.

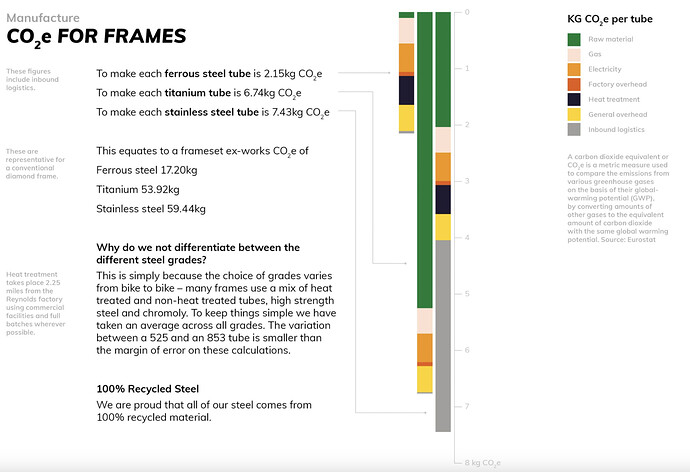

I did some extremely light research, and found that Reynolds published an environmental impact

study last year, which was a cool read!

Reynolds-Environmental-Impact-1_0_July_2022.pdf (1.2 MB)

Some light googling shows production emissions of a car range from 9,000kg(ICE) - 14,000kg (EV)

and lifetime emissions ranging from 19,000kg (EV) - 24,000kg (ICE) tonnes

We’re obviously not anywhere near that amount of emissions, but I think it’s worthwhile to be aware of the breakdown of the impact that different frame materials have.

Does any of this show up in your conversations with customers?

I didn’t see Columbus offering an environmental impact statement on their website, and am curious where/how/if other manufacturers incorporate sustainable production practices. I’m definitely much more eager to opt for Reynolds tubing after seeing that they’re working to reduce emissions.

I know that extraction is always going to have a negative impact on the environment, and that you can’t take a step without creating emissions. I feel like it’s worthwhile to push for maximum sustainability practices, and to have some transparency as a user group when we tout “sustainability”. A welcome change I’ve started to see is companies transition packing materials away from plastic and toward cardboard.

Anyways, what’s y’alls take on this? Am I beating a dead horse? Am I splitting hairs?