Wow, I had no idea!

I’m finally getting ready to build myself a BMX frame. First things first, the pivotal seat clamp arrived.

I got this part 3D printed out of 316L stainless and I plan to silver braze it into the seat tube. It’s designed for a 29.2 OD tube. Once I had the part in hand, I decided to make a small change and add an internal rib for strength. If anyone wants one, I’ll gladly share the files with you. Just shoot me a message.

Good times!

Looks great ![]()

Nice work on the pivotal post, that’s been on my list of things to tackle, just need to find the time. Where did you find the spline dimensions?

I just did some measuring and a plastic test 3D print. I’ll send you the file if you message me your email.

Not worth a build thread but after I built the white bike, I realized my black one was too long. Thought about selling the frame and building a new one but since the only thing I wanted to change was the reach and I couldn’t recreate these investment cast dropouts and yoke for any money, I did the next best thing,

New 5" headtube from @BikeFabSupply and shrunk the top tube from 21.8 to 21ish, gonna reuse the stock tube gussets and give it a quick re-spray. I’ll put a few pics when it’s done.

Hi all you BMX nerds! Been lurking here for a while and thought I’d show a few recent builds. The grey guy is an OS20 race frame with a 22” fork. Blue one is a 22” disc frame and the green one is a plain old 20”. Oh and some custom geometry bars!

Superb! I have a soft spot for the T1 Barcode type upper wishbone. I’ve got a dream of building a 26" dirt jump/pumptrack frame with that type of rear triangle.

i thought terrible 1 as soon as i saw that and had crazy nostalgia haha.

Some may remember my internal routing debate, and my ultimate decision to steer clear of internal routing on a BMX frame… Well, the frames are finally done, and I’m happy with the result. 21" TT, 74 HTA, 69STA, 11"BB, 13.75"CS

I’m happy with the blackened then clear-coated finish, and they ride great!

how are the paragon drop outs fairing with bmx use?? what drop out are you using also??

They hold up fine but I have also swapped to a design available through BFS that works a bit better for my designs.

I made a handful of these (5 or 6) at the Santa Cruz facility before they started making the frames in WI. All of the frames made in SC went to Ryan Nyquist, which he broke in very short order. The SC frames were way too light for their intended purpose, but the WI builds seemed to hold up very well.

Ryan rode a (SC built, I think) Bontrager in his first Pro contest in Seal Beach, CA, to a respectable 5th place. He was immediately picked up by Haro, and the rest is history…

Cheers,

KP

Finally found some time to organize and clean my shed up. Which meant I could do some brazing. Tacked the front triangle together.

Then brazed it up.

Don’t look closely at any of the other joints, but I’m pretty proud of the bottom bracket.

Hopefully it won’t be another 3 months before I get the next update for the seatstays and chainstays.

I finally finished my frame. 5 months after I started. That’s a pretty good pace for me. I don’t know how you all make your fillets look so nice. I just have hand tools and my thumbs and fingertips are raw. I can’t use my fingerprint to unlock my laptop anymore.

I’m excited about this though. Here are some more photos before I paint the bike. I’ve got some parts showing up and then I’ll paint it and I’ll post a few more photos. I’m just so happy with how this turned out.

I like the rear dropout (technically, fork ends since they don’t ‘drop’ out) treatment. What dropouts are those? did you make (or SendCutSend) them?

I might fill in the ends of the stays - just for insurance. I know for TIG they often leave them open but probably to avoid introducing a second joining technique. If you start brazing then you have to soak and it sort of defeats the cleanliness of TIG. If you’re already brazing and it’s fluxed up, you might as well add the extra strength by filling in around the dropout tab inside the stay tubes. Then, because I think it looks more finished and professional, I would scallop the ends of the tubes with a large round file - at the angles you have there. Be careful with it so you don’t dig into the dropout.

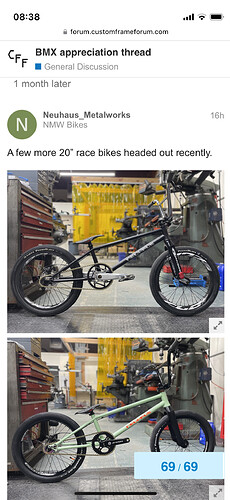

Nicely done! I have a 24" design waiting for me to get through a few other projects.