Hey all! I recently discovered the forum and have enjoyed reading through the active discussions and build logs; it’s awesome to see people sharing their frame building experiences and great ideas/techniques.

I’m a university student in California and am fortunate enough to have access to some amazing machine shop equipment. I discovered frame building during my freshman year through an on-campus club and quickly fell down the rabbit hole. Below are some of the things I’ve made over the past 2 years.

Cargo bike (Spring 2021)

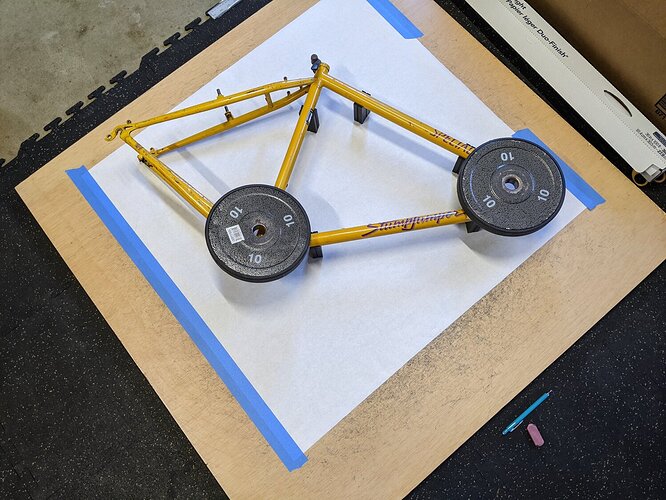

This was my first framebuilding project. School had transitioned to all-virtual, so my apartment garage became my workshop. I wanted something that would mostly obviate the need for a car (my town is pretty bike friendly), so a cargo bike was a natural choice. I salvaged the rear end from a Specialized Stumjumper and welded a rectangular box-section longjohn frame. I found Phil Vandelay’s video on DIY cargo bikes incredibly helpful and referred to it many times throughout the build process.

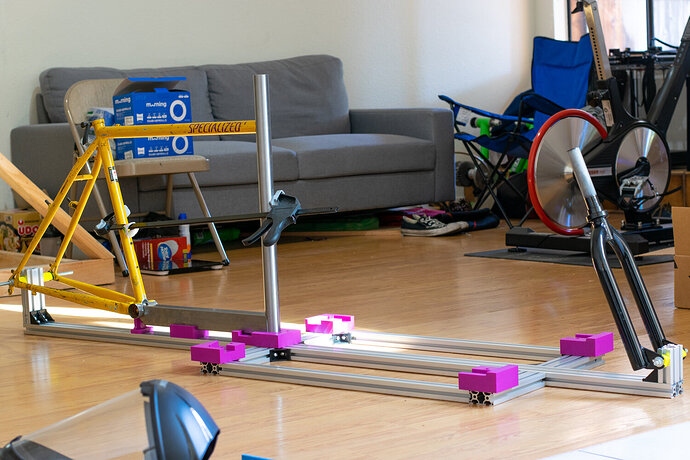

I did all of the tube mitering/prep using an angle grinder and benchtop drill press, and created a basic frame jig out of aluminum extrusion and 3D printed pieces. I can’t overemphasize how game-changing 3D printing was for creating fixture pieces and miter templates. Some photos are posted below:

Simple wheelbuilding stand I made from 3D printed parts + aluminum extrusion

Measuring the Stumpjumper frame

Cargo Bike Jig

Finished frame. Powdercoated in desert tan.

Full Suspension Bike (Summer 2021)

The on-campus machine shop reopened during the summer of 2021. I dove into a full-suspension bike build and learned how to use a manual lathe and mill to create frame components and welding fixtures.

I created a MatLab program that graphically calculates the various kinematic responses of a single-pivot/4-bar bike - essentially a rudimentary version of linkage. I used the optimization function within Matlab to generate a pivot point location based on desired anti-rise and anti-squat characteristics for a given COG height, gear ratio, and bike geometry. You can find more details (plus some interesting animations) here if interested.

Rear triangle

Rear triangle jig. 3D printed dummy tire included.

Front triangle jig

Fully assembled bike

First ride. Rode/rides great!

Center Steer Hub (Spring 2022)

I took some time off school to intern at an automotive company and had a very negative experience. Building bikes was far more fun. I returned to school for the spring quarter and learned how to use the CNC mills in the shop. I took a singletrack vehicle design course and decided to make a center-steer hub for my course project. To save time, I retrofitted my old cargo bike to acccomodate the new center steer hub. The finished product is laced to a 24" wheel and allows for 35 degrees of steer from center. Additionally, the hub axle connects to the frame via clock-able chips, allowing you to quickly change your headangle to any desired value.

I first validated the performance of the hub using the handling models presented in my class. After, I machined the hub from several plate sections, bolted it together, and laced the wheel. I ordered a large stainless steel brake rotor from Sendcutsend and welded a new front section to my cargo bike. I ran into several challenges during the build:

- Caliper-spoke interference: I hadn’t considered the brake caliper hitting the spokes. It did. I had to shift the brake+caliper assembly out by 1/2" to make everything play nicely together.

- Eccentric bearing bores: I didn’t understand that clamping a large, thin plate during machining may cause deflection. My bearing bores, which were great while clamped, deformed immediately after the clamping force was relieved. However, I wasn’t able to detect any effects of this distortion on the 100’s of miles I put on the hub.

Sporty? Cargo Bike + Frame Fixture (Spring/Summer 2022)

I wanted a new, better-handling cargo bike and an improved frame fixture. I designed the frame fixture around a long rotisserie-style aluminum extrusion that could swivel+lock into place for easy weld access. I machined ball bearing sliders that attached to the extrusion and provided mounting points for different fixture pieces (e.g. head tube rail, seat tube/bottom bracket mount, etc.)

To validate the frame fixture, I made an omnium-inspired frame. The final product handles great and continues to be my daily driver (rider?)

Fixture locating seatstays

Finished bike. The tote isn’t very elegant but certainly holds a lot of stuff!

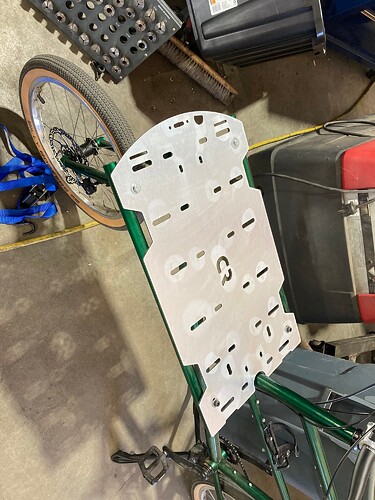

ACM cargo bed. Key features include a built-in bottle opener and logo.

Steering system. 4-bolt spider on the fork + steerer tube allow me to change the steering system to chain or cable in the future.

Full-Suspension Electric Cargo Scooter (Fall 2022)

This was an interesting project that I took on as a contract job for a guy in the Bay Area. He wanted something that could carry his kids and handle the rough roads around the SF/Oakland area. There was lots of scope creep throughout the project and I felt pretty relieved to deliver the final product.

My job was to design and fabricate an initial handling concept. I created a swappable linkage-driven single pivot suspension system that allows the rider to compare the two swingarm pivot points without changing the shock tune / motion response. The lower pivot point is designed to isolate the suspension from drive forces for a lower COG (just rider) and the upper pivot is for a higher COG (i.e. large cargo load). Having pedals + chain was dropped partway through the project and the bike became a 2WD electric scooter. Notable design elements include a remotely deploable kickstand via handelbar lever, custom battery compartment + brackets, removable cargo rack, and support for most Yuba accessories.

Various CNC Components (2022)

In addition to bikes, I’ve created various smaller bike-adjacent tools and components. These include:

Custom fusion weld bottle boss machining fixture. Can make for a few cents of material per boss and around 80-100 per hour

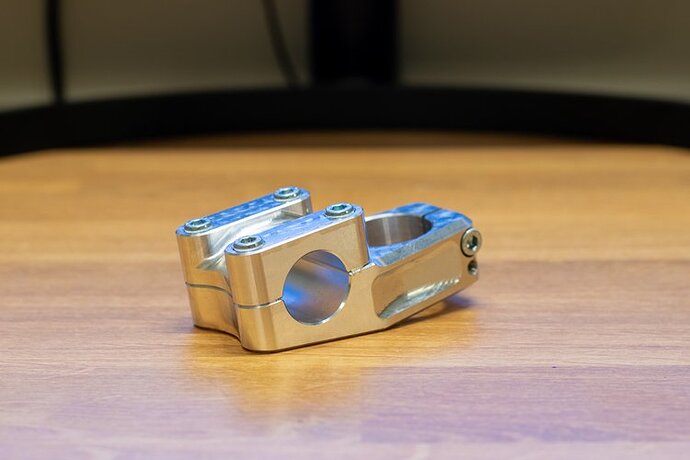

Square-taper crankset, stem, and loose-ball hub for small bikes

5-Axis MTB stems

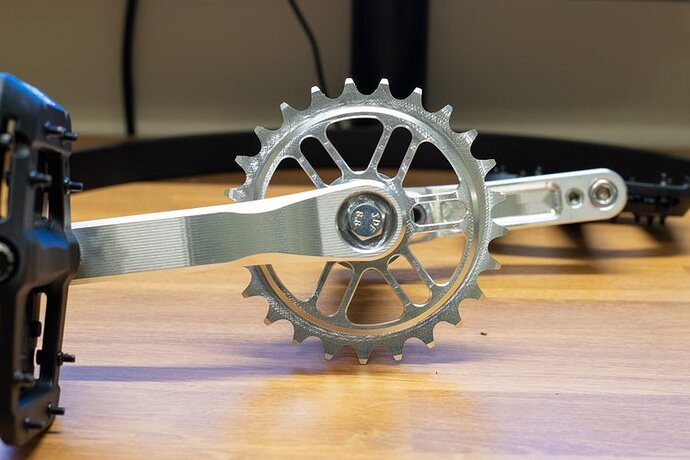

Parametric narrow-wide chainring

Thanks for reading!