@Pursuit Thanks for starting this discussion!

That is a great point. I honestly think for frame building as a hobby, carbon fiber bikes are the lowest barrier into the craft:

- no large machine tools

- no large space requirements

- no dealing with gasses and flames

I can see a world where in 5-10 years, carbon fiber frame building is the norm, not because of performance characteristics, but because it has the smallest space constraints to get into it.

I have played around with composites before, but never on a bike. This is something that I am eventually going to get to in the next year or two.

From my naive perspective, the current barriers to carbon building are:

- lack of knowledge

- lack of “carbon weldmets”: dropouts, BB’s, headtubes, etc…

Imagine if paragon didn’t make dropouts, bb’s and headtubes for titanium and steel. It would be so hard to build a metal bike!

Maybe this exists, but if someone made a gravel/road bike chainstay-bb-dropout subassembly, specifically for hobby frame builders, that would really take down some barriers.

Then there is the topic of 3D printing + carbon fiber, which is a great match:

This is a cool example from Brackish Cycles

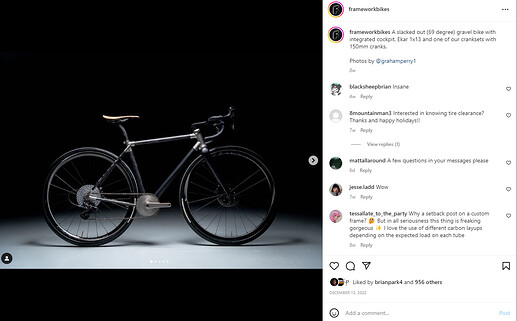

Frameworks is doing some really cool stuff winding tubes and doing testing:

And you could mold/make your own parts like Montenegro

This is from my perspective, and maybe @Pursuit can chime in here:

I think knowledge is the biggest barrier for carbon bikes. Metal custom frame building has had the benefit of 50 years of trial and error and tribal knowledge. Metal tubes are also much simpler to understand and predict their behaviors.

I can easily create a fully parameterized 3D-printed lugged carbon frame in CAD, but I don’t even know where to start with the tubing diameters, wall thicknesses, epoxy, etc…