Have you priced out steel lugs as well?

Stainless Steel would be $300-400. When I get a chance, I need to research 3D-printed aluminum. It could be the best material to make 3D-printed lugs:

Here is Pinarellos project with 3d printed aluminum:

Hi Everyone,

I teach a class about building custom carbon frames. Honestly, like Carl said, if you are starting from scratch I believe it would actually be easier and cheaper to make some carbon frames vs. steel/Ti or at the least, about the same. Many of the tools for tube to tube are the same ones you would use for metal construction.

I think the biggest hurdle right now just that there isn’t any real infrastructure for carbon framebuilding. When it comes to steel/Ti we can go online and get a myriad of supplies, dropouts, tubes etc and this just isn’t the case for carbon. If we had easy access to dropouts, chainstays and the like it would be no problem to build quality carbon frames in any garage with some ingenuity and the will to do it.

I don’t see this getting any better. I and a couple of others can’t drive this all by ourselves. Most hobbyist know that you can make metal frames in a garage/small setup but people just really are not aware that the same thing is true for composites, thinking instead that its requires some sort of “aerospace” setup. I could have some of my sub-assembly designs made up in Taiwan but I am unwilling to take the risk I would get stuck with 300 sets of drops that all you guys would buy if just, they were 5mm this way or that way…You know herding casts if you will.

So, I can help answer a few questions here or there. Of course, I try to make my way by teaching you guys for dinero so I don’t feel like giving it all away but sure, I can help a bit.

I am also working on putting this info in an online course format. Its a big job so don’t expect it quickly but it would be a great value and walk people through the process of making a safe composite frame using commonly available materials.

Thanks for having me.

Dave Bohm

Bohemian Bicycles

Thanks Dave, and welcome to the forum!

Agreed. The custom carbon frame seems limited by:

- carbon knowledge

- carbon parts supplies

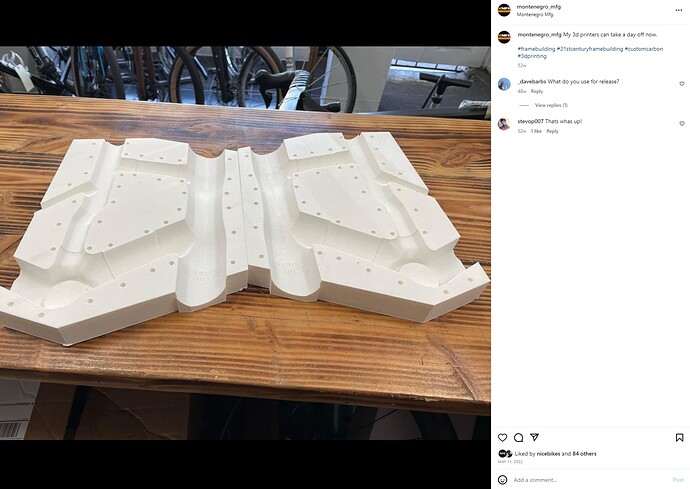

An online course would be a great first step. I would definitely be interested. As mentioned above,I think 3D printing is a great companion to composite manufacturing, and it’s only going to get cheaper/more accessable. Either through printed dropouts and or 3D printed molds a la MMFG:

I think one of the issues when comparing carbon to steel as a “garage build” material is the inability to move it around. With steel if you want something moving 5mm you can just bend it. But carbon will always be the moulded shape. I think you have hit the nail on the head with that really.

If people want to do more DIY carbon stuff then it just requires a mentality shift away from steel building. Carbon can be an amazingly material and changes can be very easy to implement, if you know the correct way to do it.

Following on from my early query, would it be practical/advisable to bond/wrap a carbon tube to a steel/aluminium/titanium component, eg BB shell, head tube or dropout, in a DIY setting? I know there can be issues with galvanic corrosion with aluminium (but apparently not titanium?) and of course you’d need compatible bonding/laminating agents. Obviously there are plenty of metal components in myriad mass-produced carbon bike frames (I’d imagine the vast majority of these are aluminium) so it must be possible.

I used to play with carbon fiber frames, I even made a bamboo frame with it, I made tests with kevlar as well and natural fibers like jute, it’s an interesting field.

I always wanted to try this:

I’m no expert, but I’ve heard from industry types that they use a layer or two of glass fibre to effectively insulate the carbon from the aluminium.

In Chinese or shall we call them far eastern production frames the layup schedule often describes black fibreglass (basically black dyed) in the seat post area, however they have also been known to fill the frame with it instead of carbon on lower quality frames.

I have been conversing with a member of the frame-building community who works for an aerospace company and he has pretty much said the galvanic fibreglass protection in not too common these days and has been replaced by far more modern and efficient methods.

Please, could you describe “modern and efficient methods” against galvanic corrosion?

Hi! I am building carbon tube to tube road bike frame. Now I am at phase to glue tubes together.

When I will glue headtube toptube and seattube…I could have toptube fully closed by headtube and seattube.

My question:

Is it problem to have top tube fully closed? Is it important to create holes in headtube and seatube or may be better to create some little hole (1mm) downside of top tube?

Thanks for yours opinions…it is my first attemp to create bike frame.

I am not an expert and my experimentation with composite materials are somewhat limited, I would be worried about condensation in the first place but now that I think of it, what about the heat generated from the curing process (of the joint in this case), would it mess with the pressure of the air in the tube? Could it create some “blowback” or bubbles in the area as air increases in volume and tries to escape somewhere?

I remember my curing process was pretty hot - just something to think about. ![]()

Yes! You are right. I think mainly about condensation but heat generated pressure could make some unexpected result. Thank you for your hint. My postcuring process run at 70C.