That’s going to be a great place to spend hours making stuff!

The sliding scale to measure mitre lengths, I’m stealing it!

Your frames are inspiring!

Absolutely! ![]()

I just want to get to lighting the torch! It has been too long now!

Whoa! I’ve been looking for something like this! What dimensions did you use for the spacing?

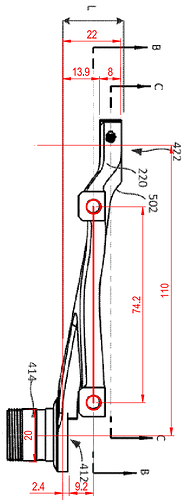

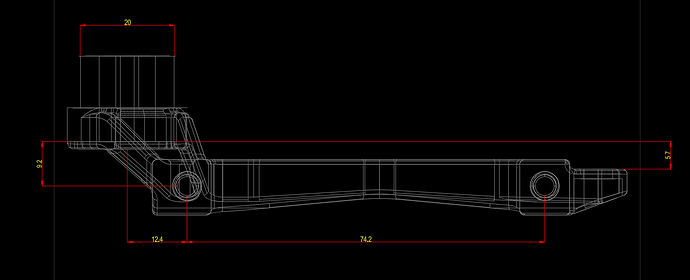

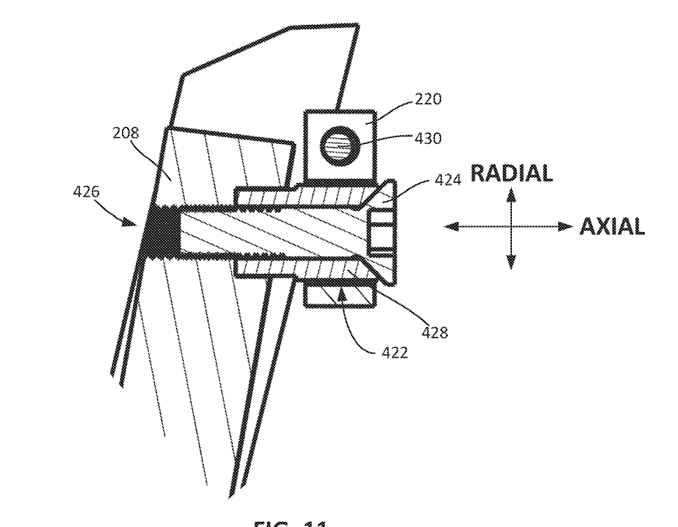

I just mirroed the UDH insert, so 20x12.5 hole. 7mm from frame to axle. The anchor bolt is inline with the front post bolt.

Neat! How are you planning on having the adaptors made? 3DP aluminium? Is that risky? Keen to see how the next steps go.

No I’m going to use 316 or 17-4. Nice and strong and stiff. given that it’s a slender piece. Might pay for them to be polished. BLING!!

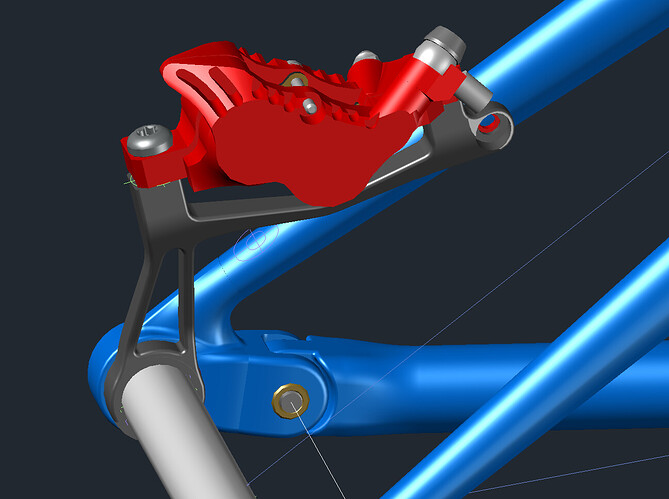

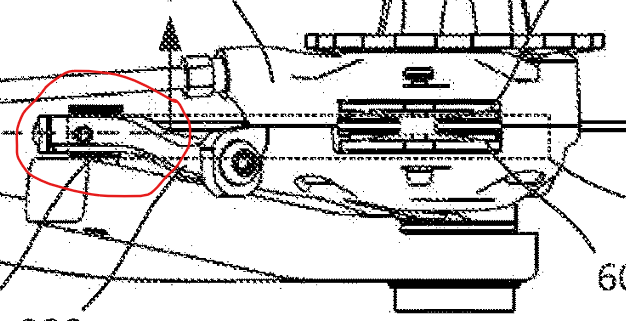

Did you have to do any trickery to make it line up with the seatstay?

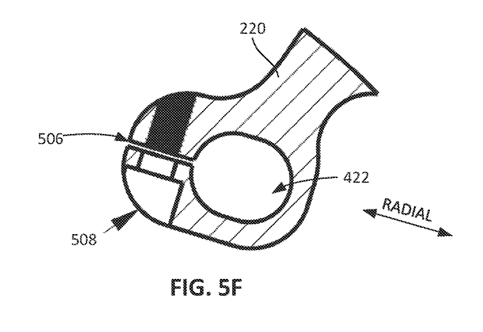

Other than model everything as accurately as I could, it wasn’t hard to set that bolt up. I just ran it inline with the front post bolt and rotated the bracket until that sat on the centerline of the seat stay. The biggest unknown at the moment is the shape of the taper on the seat stay. I need to grab one and accurately model it. I’ve given myself a 1mm gap from the undrside of the flange on the boss I’'l braze into the seatstay to the lofted shape of the current modelled seat stay (which is actually a road fork blade from the Columbus catalogue) . That 1mm will give me a bit of float and I’ll can just fill the gap with the braze. I’ll look at a boss that wraps the seat stay at some point with some green that I can machine back to spec.

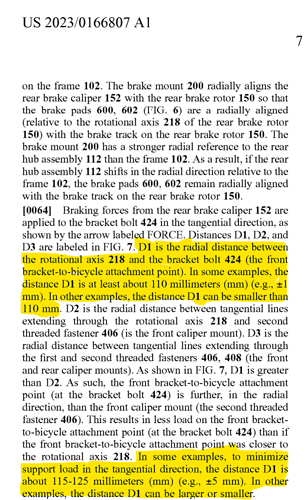

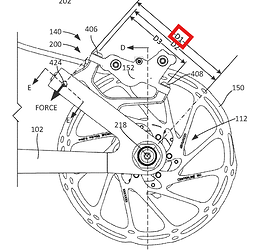

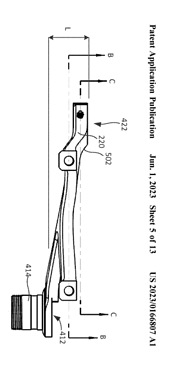

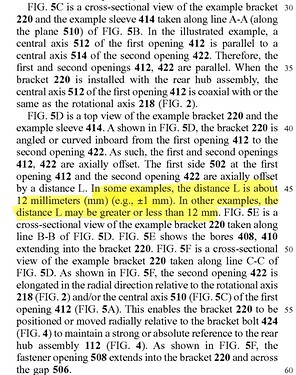

Sean, This looks so damn good! What length did you use for your fixing bolt from center of axle? I dove into sram’s patent and they call out 110 and 115-125 as potential lengths.

Good spotting. I didn’t see that and started tracing the line drawing a while back. When I sat down a couple weeks ago to reasses it I decide just lay it out to suit myself with only the ‘UDH’ hole being the fixed parameter. I just measured my model and I’m at 97mm radial distance. I did ponder going longer to lessen the torque as they mentioned in the text and it would be easy enough to adopt 110mm. That is one of the dimensiosn that would have to be settle on if they wanted to push this specification.

Another variation that has come to mind is the bracket is a base piece with slotted holes in it that you attach a bracket similar to a flat to post mount adapter and you just slide it along for each size disc. Not sure if it’s wararnted though. Who am I kidding? This is the bike industry. Let’s make it more complicated! ![]()

Nice! I like how it tucks in even more with the update.

I’m trying to find the inboard offset from axle to bolt mount. So far have only found axle to bolt head distance (12mm)

you could trace teh image in your CAD program of choice. Use the post mount bolt holes as your reference to scale.

A couple things not quite adding up there but that may be deliberate from SRAM. Interesting to note some cool design features when you tart looking at teh drawings in detail. The radial mount is sitting in line with the disc which means the radial mount has to sit out at the minimum 110mm but that means it will only fit a 200mm disc in the rear. If you wanted 220 then you’d have to have the 120mm radial dimension. The advantage of this is that there wouldn’t be any axial (in relation to bike centreline) torque on the bracket, or not as much as the axle end is still offset.

I’m only at 5.7mm to the radial mount face so need to have another look at that. Their setup that they have allows for the frame to be where it needs to be and the bracket just sits along the spigot and clamps in position. So my bolting the bracket against a face works for my bikes but would need to able to be adjusted. This is the crux of the SRAM patent I believe.

I can see a setup that allows for the bracket to float on the spigot and allow for the stays to flex in a flex stay frame. That woudl be pretty cool.

dang that flex-stay-float-on-the-spigot move is spicy, let alone the brave new world of antisquat someone is going to have to model, including the further flex being induced by braking…

I petition we call it “float mount” but exclusively pronounce it in a really rich Aussie accent for maximum confusion?

Haha. I was thinking about it more and I would just rotate the bracket down and mount the radial bolt on the chain stay and not load up the seat stay at all.

Would that work on a full suspension bike? Because then you would have a pivot between the axle and the hole for the brake mount.