HA, if you want to call it F(low) mount you can just say so… ![]()

Haha. I like it. Royalty cheque is in the mail. ![]()

If it’s a flex stay there are no pivots and you’d mount the radial bolt on the chainstay. If you wanted to mount on the stay you’d have to allow the bracket to rotate at the axle and then the radial mount would need to room to creep on the bracket. That would allow the stay to flex as it needed to. Whether you used a bush or a bearing at the axle for the bracket would come down to sealing. There is just enough room to fit a slim line bearing between the axle and the frame end so the bracket rotates around the axle. On a flex stay though, there is no benefit to mounting the brake on the seat stay so you’d just drop it down and save the complexity. Unless you want to flex your design chops. ![]()

the only downside I can think of for the chainstay mount is bolt accessibility and caliper clearance (frame width)

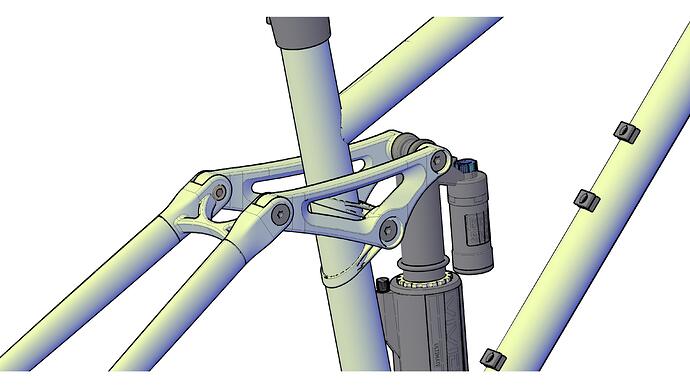

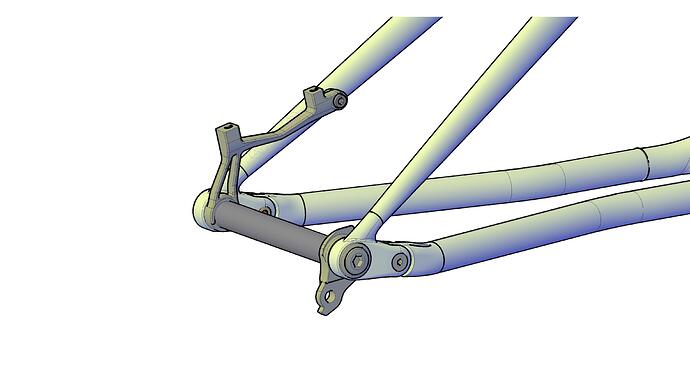

Its not too bad. I did an IS mount with a post adapter on the chainstay on my Demon XC last year. The seat stay ran out side it and everything was in the normal sorted of spacing.

I never took any decent photos of it but here a couple of screen snips…

These are life-saving diagrams, I’ve been stuck on brake mounting for ages!

Finger is hovering over teh keyboard to send to the printers. A little eye watering to the cost of the set of prints.

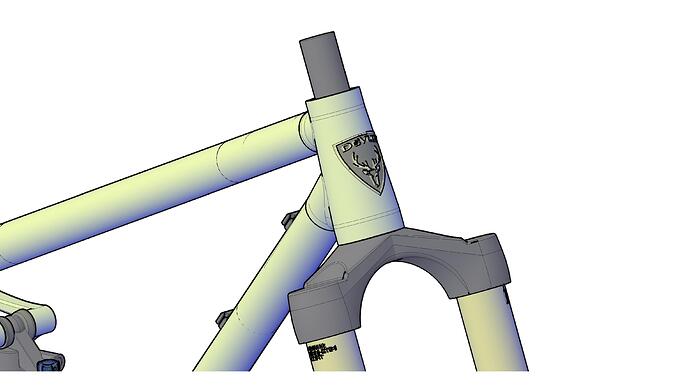

A version of the tube rocker. Not getting printed though.

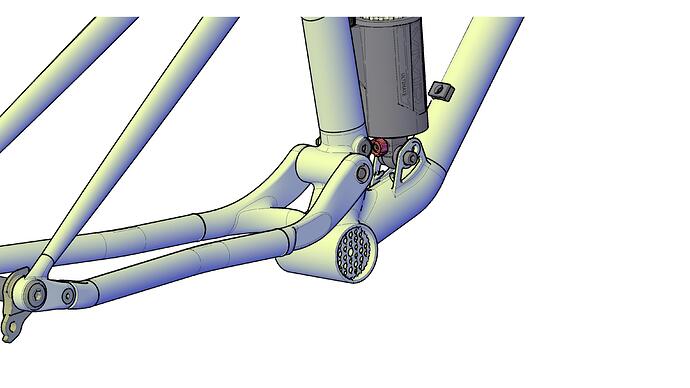

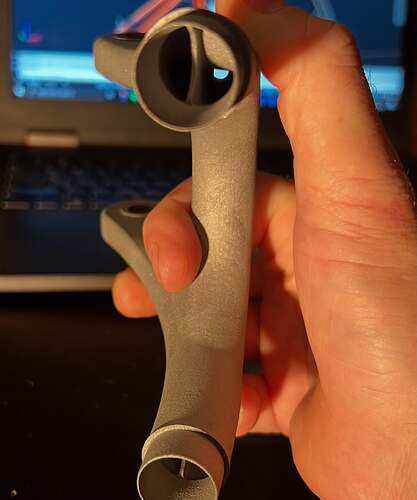

3D prints from Protosoon in heat treated 17-4PH for the next iteration of the Jester Enduro frameset.

Very nice collection of parts there. Can you share some details on the seat tube rocker pivot?

Pete

Cheers. The rocker pivot just slides on to the seat tube like a sleeve and gets silver brazed into place. The pivot hardware misses the OD of the seat tube by about 1.8 mm.

It’s a very elegant solution to a seat tube pivot. Did you print grooves for snap rings to constrain the bearing shoulder?

Hope this works, I’ve been tig welding a similar type of part using a thru bolt. It’s about 65g in steel, I’m curious how much your part weighs.

Mine is 76g as printed. I could pull some material out but since it’s an enduro big hit bike I’m not to concerned. The bearings I am using are shouldered so don’t need a circlip to create the inner stop. That way I can just run the ream straight through both sides and know the bearings will be in alognment.

Neat, I had not thought of that. You are facing the fitting along with reaming then eh? Still with a compression id tube

Yeah, but I’ll have to turn teh frame over to face the other side. Yes it has an compression tube wich actually passes through the bearings so ID of bearings is 12mm and pivot axle is 10mm. Same as on the main pivot.

About as minimal as it will ever get.

Well done!