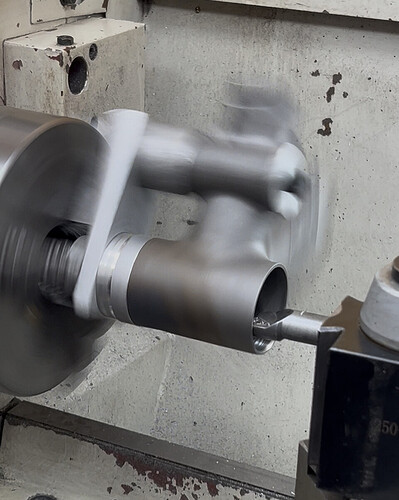

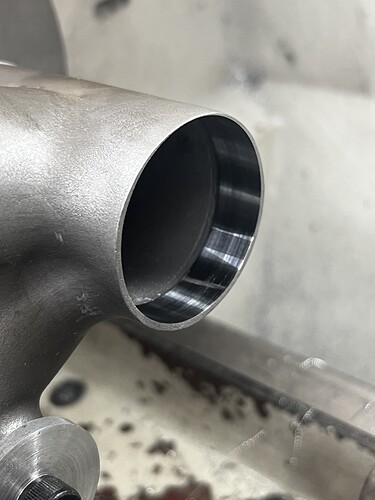

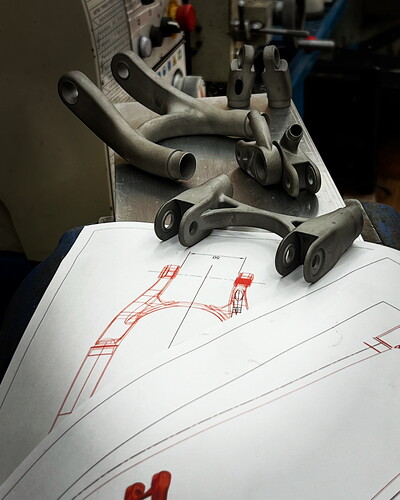

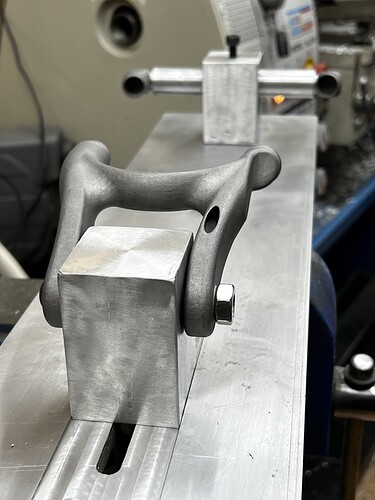

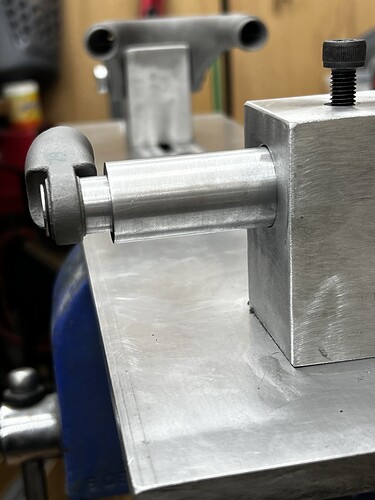

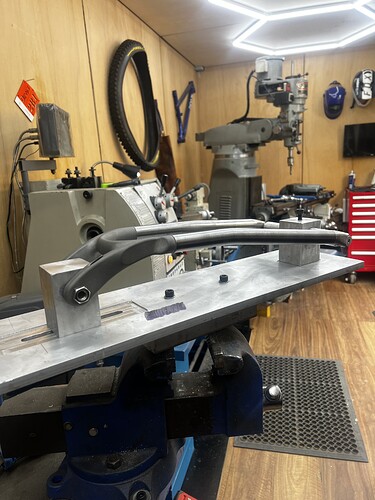

A photo dump of putting the new Jester together. There was an issue with warping in the BB shell but after talking with a few people I understand why it’s happened and what I can do about it. To fix this one I machined up two inserts so instead of T47 it’s now BSA.

I wanna hear more about the warping BB shell and what to do about it. Your 3D prints all look so great!

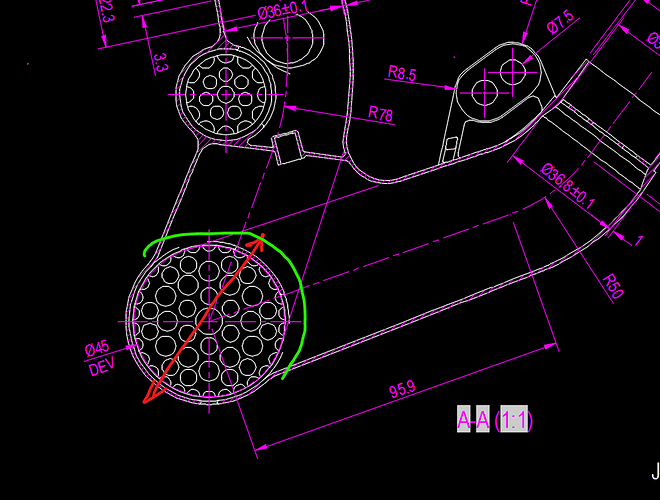

So what I have been able to figure out is that the volume of the material from the bottom of the seat and down tube (green area) in it’s cooling from both printing and the heat treatment has drawn it in a little in that area. What that means is it ovalized the BB shell part where it was thin (red direction). The company said they didn’t remove the discs before heat treatment but I think they may have. I can’t see how the shape would have drawn in with the discs in place when heat treating…but that said the warping may have occured during printing. Another builder uses a similar disc in the openings and he has stable dimensions.

Interestingly, the head tube I did not use the discs as an experiment. It has the seats for the bearings in it though and they are modelled off the Columbus braze in inserts. There is a substantial amount of material and have the TT and DT sockets adjacent. These were within the 0.1mm tolerance I had expected. I had modelled in a little extra material for machining to size. So that went really well.

My plan is to model in extra thick ring for printing.heat treat and get them to machine the T47 threads for me or have another crack at cutting the threads on the lathe. That is actually hard and am having to learn some real idiosyncrasies with it. I didn’t have much success with maching the threads in the 316 material I was able to get for the inserts to fix the BB and ended up brazing in some chro-mo BSA shell sections.

Such a shame that raw doesn’t stay like that very long. They look sooooo good when raw.

Love the rocker mount lug.

Im talking with Joe at KVA to do a full stainless version later in the year. I couldn’t get my ducks in a row right now but that is definitely on the cards.

Very ![]()

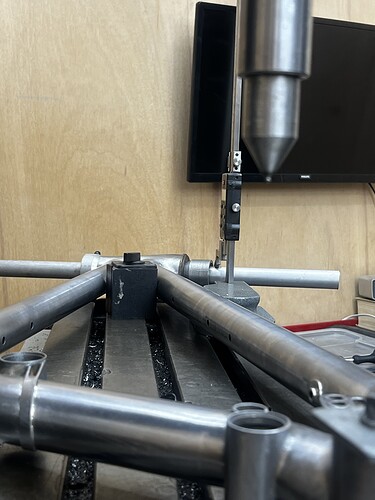

Oh lord. This front triangle is a work of art.

what are we looking at in that first picture?

I reckon that’s a bust up after the stays bridge went on backwards.

Which begs the question Sean (@DEVLINCC) how much of the assembly did you re-use? Assuming that the 3DP bridge was ok after a bit of clean up but new stays were needed?

i missed the chapter where the bridge went on backwards!

It was over in the framebuiding failure thread.

Yes, I brazed the bridge on backwards. It has space underneath for the rocker to rotate into. There is a video on my Insta showing how I unpicked the stays. I was able to reuse everything Thankfully as new stays would have been a week away and leave no time to get the frame ready for the show.