I haven’t been actively building for a while now and I got rid of a lot of my tools (frame fixture, torch etc), but I’ve had the itch to build myself another hardtail recently. So here’s a build log that I hope some of you may enjoy.

I’ve had a pretty good idea if what I wanted this hardtail to be ever since I finished and delivered a customer frame back in 2020 - it ended up being one of those bikes that I wished I’d kept for myself (though it was the wrong size, so that was lucky for the customer I guess).

It was a clean 29er singlespeed built around a 120mm fork. Columbus Zona tubing. PMW 44mm headtube, BB and Rocker dropouts finished in a timeless Nardo Grey with black logos.

Something about it just ticked all the boxes for me and I’ve wanted one for myself ever since.

Here is a photo of it in its natural environment:

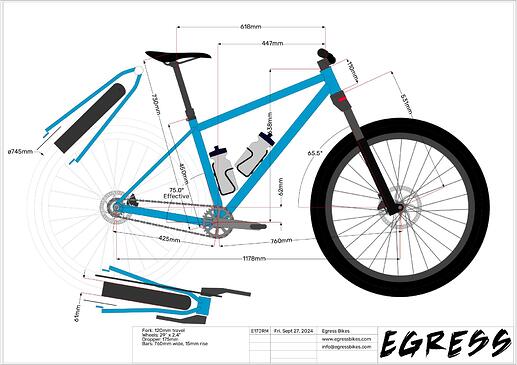

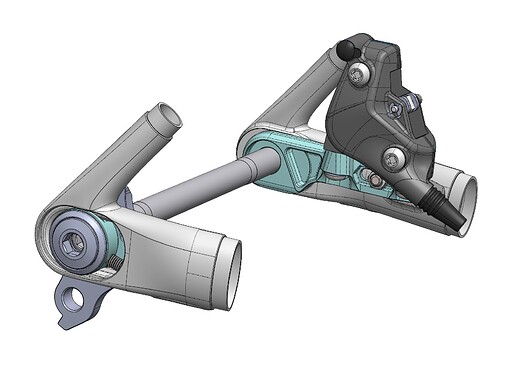

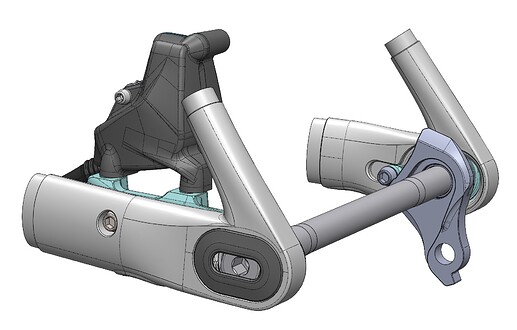

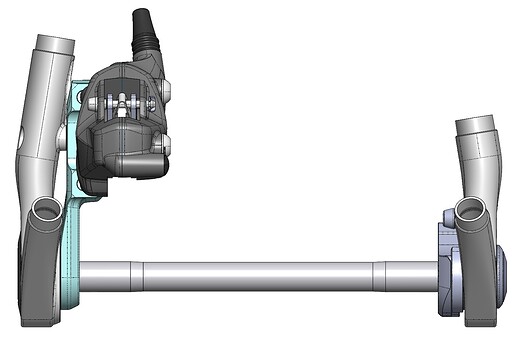

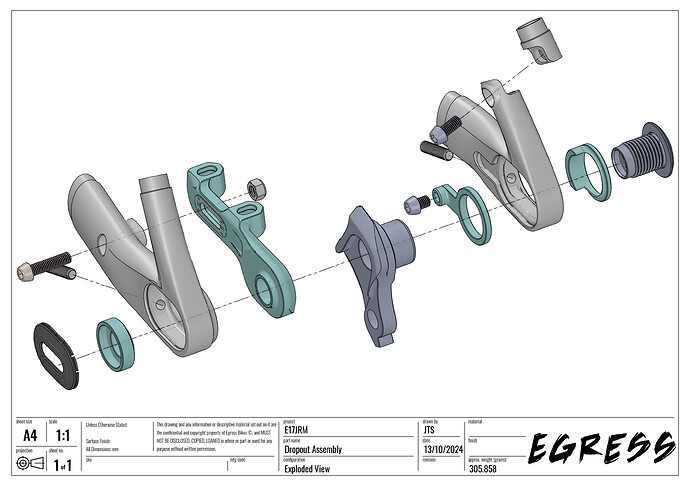

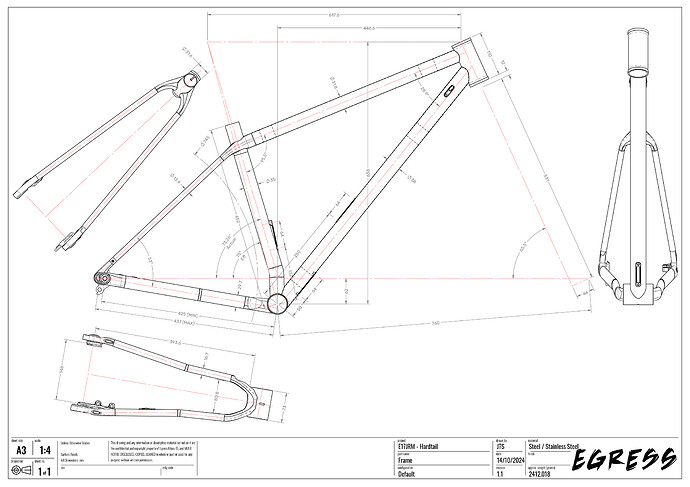

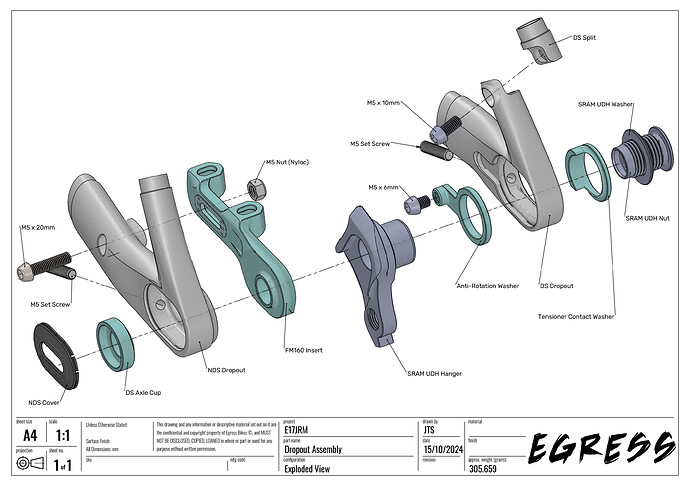

Fast forward to earlier this year and we got some stainess steel 3D print samples of set of UDH dropouts I desiged for my day job. The idea was sparked that I could build a frame for myself to “test” them, so I got to work and dialled in the geo in BikeCAD.

[Some geo tweaks may still be needed.]

Digging through stuff in my garage, I found a bunch of leftover Columbus tubes, a 73mm PMW T47 BB and a selection of 44mm headtubes and hatched the plan to use what I have instead of buying new tubes.

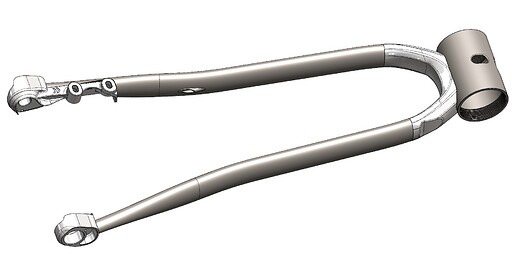

The seatstays I found were just a set of straight Columbus SL, the chainstay option I initially picked from my leftovers box was a set of Columbus Life 16 x 30 short taper with a mellow road bend, and the Ø31.7 Columbus Spirit tube I found would not be long enough to use as a toptube. So this is where the simple “leftover tubes build” ended up getting a bit more complicated.

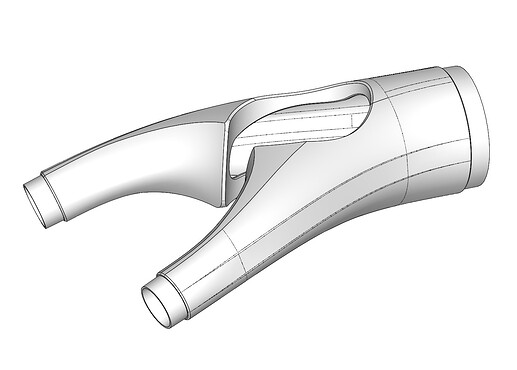

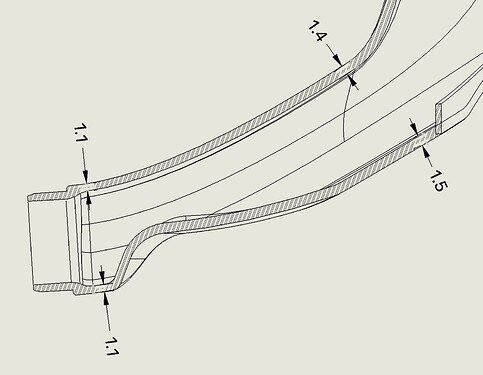

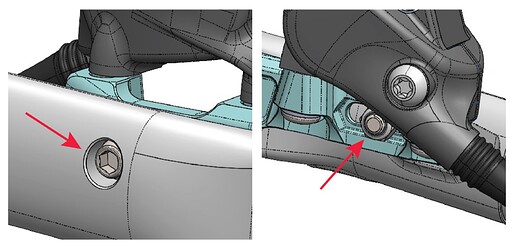

I don’t have a tube bender and no way to shape oval tubes, so the natural decision here was to design a set of yokes to be 3D printed out of stainless steel. This is where I had to continue the project in SolidWorks instead.

The SS yoke would conveniently also take care of the too short TT as I could simply extend the 3D print a bit to give myself just enough length to allow it to be mitered to the TT and have a straight-cut join to the yoke section.

[I know, I know - this yoke is very similar to @Daniel_Y’s design. Not that many options when trying to flow three tubes together. But I reckon I’ve added some of my own subtle ‘flair’ to it.]

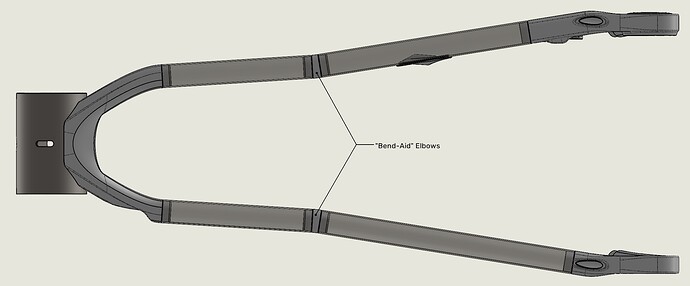

Next up was to design a chainstay yoke that would marry the road bend chainstays to the T47 BB shell while giving me the clearance I wanted. Giving this frame room for up to 29" x 2.6" tyres, but I’ll probably end up riding 2.4" tyres for the most part. I even managed to get the stays to work quite well with those prototype dropouts that kind of kicked off this whole project.

[Yup. Flat mount.]

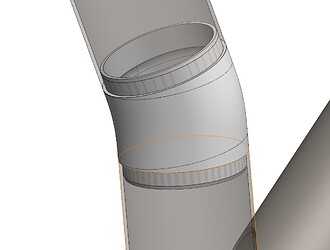

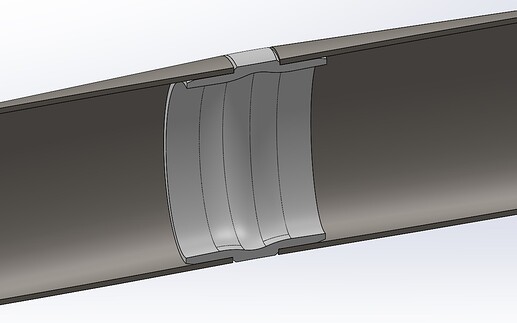

Next up was the seat tube bend. As I mentioned before, I don’t have a bender and didn’t feel like bothering other local builders to help me bend one, so while I was at it designing stuff to be 3D printed I figured I could make a printed elbow that can be used with just plain 4130. Easy.

[It’s a Bend-Aid fix.]

End part 1.