Happy new year to all you bike fab maniacs!

So the other day I had the opportunity to purchase a GRX groupset at a very good price and couldn’t turn it down. This obviously left me with no other possibility but to design and build a frame to mount it to.

But alas! Having only ever ridden (and built) squishy bikes before, that focus a lot more on descending scary rock gardens while stood up on the pedals, I have absolutely no clue what I’m doing, especially geometry wise.

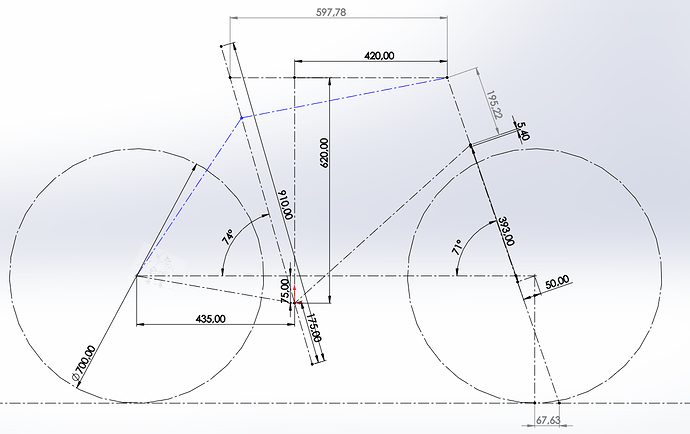

So I asked chatGPT to give me a few geo numbers for my 189cm height/91cm inseam, and I also asked a few people who may or may not have some more experience with the geometry of a bike that is mostly ridden while sat down. This is what I ended up with so far: Feel free to criticise/suggest other numbers!

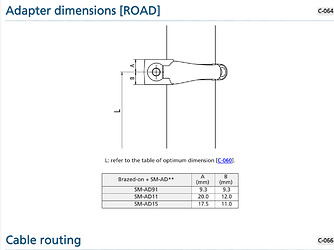

The fork I’ve taken the numbers from is a Ritchey 1 1/8" carbon gravel fork. I chose this one because it is less “meaty” than other carbon forks around the top end and I hope this blends in well with a paragon 44mm head tube and zs44 headset cups. Again, please correct me if this sounds stupid to you ![]()

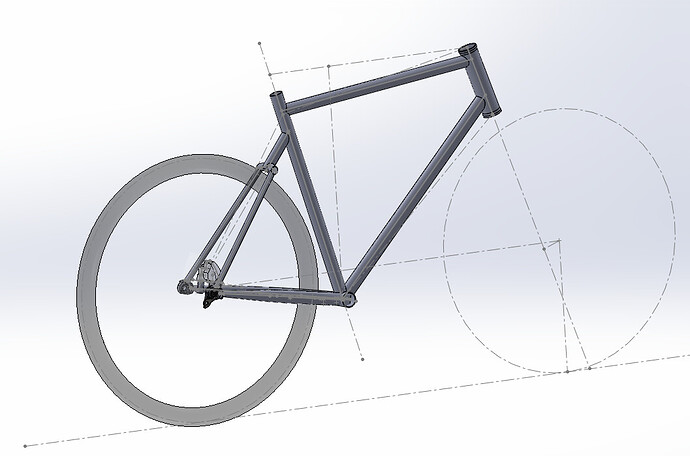

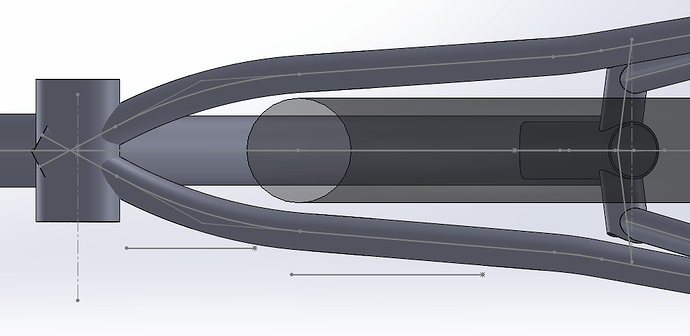

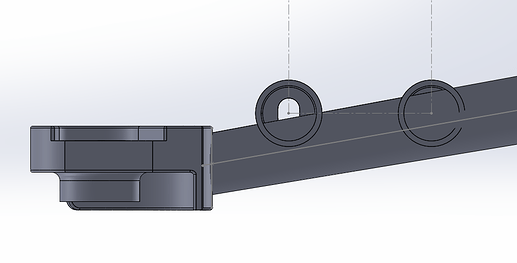

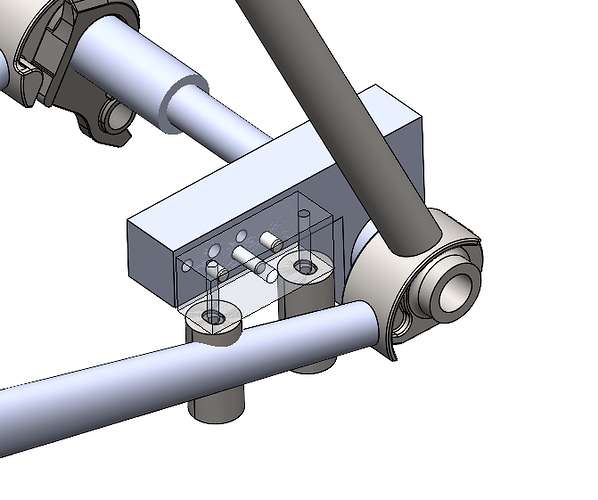

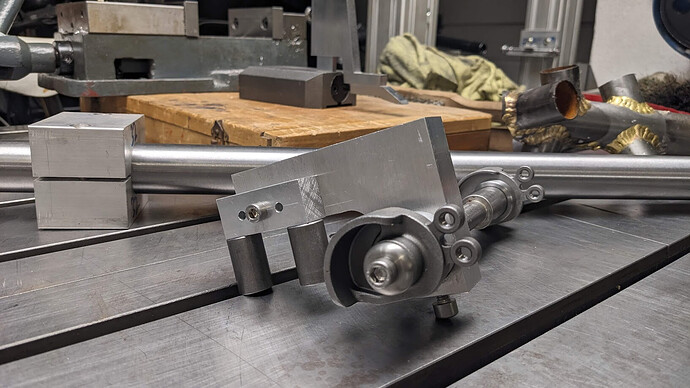

Alright, a few more choices that are already pretty taken are the chainstays (Deda MPO240C2022) and Allotec C82 dropouts, because I already have them in a drawer… Apart from that, everything is pretty much up for discussion, especially tube diameters. So far, I’m shooting for a 35mm DT, 31.8mm TT and the seat tube, I’m actually a bit lost. Most tubes are too short for my size, and I don’t really understand the benefit of the external butting of many of the columbus tubes. Some advice here would be greatly appreciated!

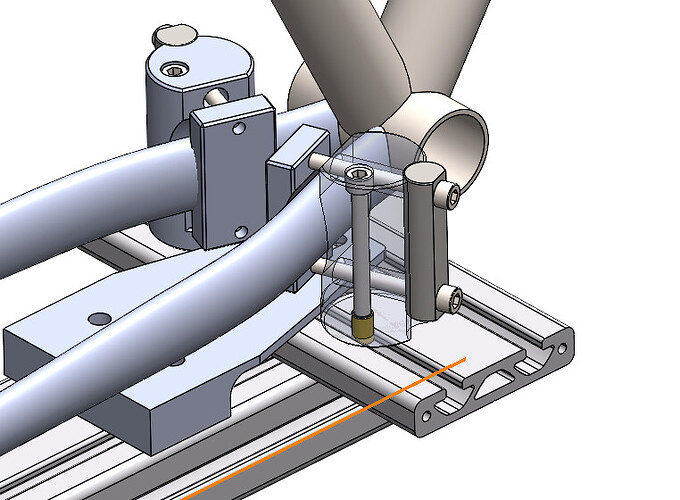

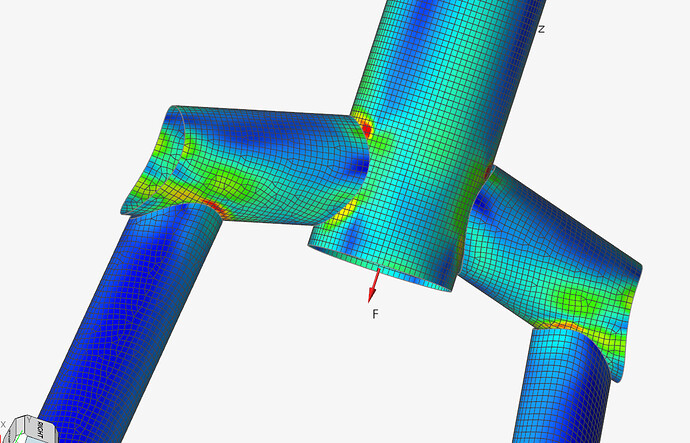

Since I don’t have a tube bender, I will probably build wishbone seat stays (and because I think it looks cool). Also because it looks cool, I would like to have a dropped seatstay junction, which makes positioning the FM mounts a bit finnicky, but we’ll see…

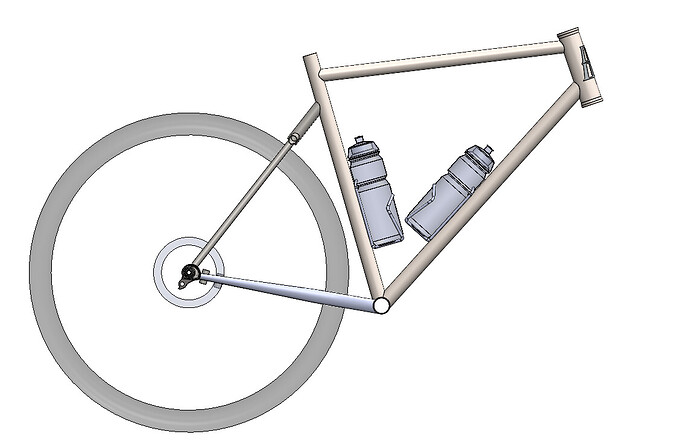

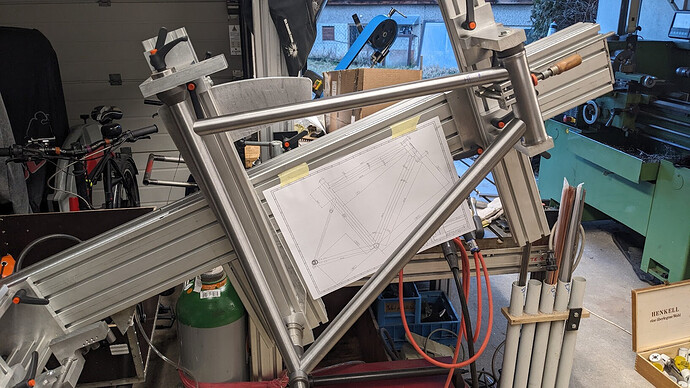

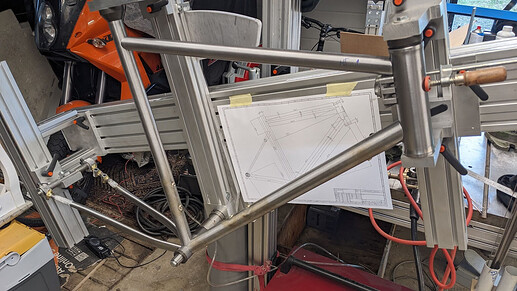

So this is where I’m at so far:

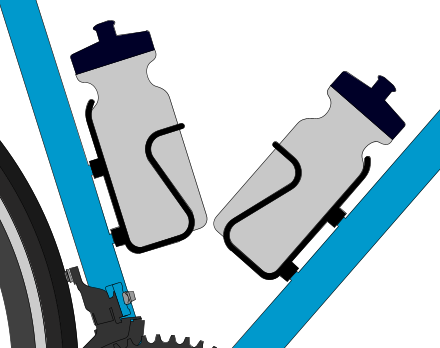

Chainstay will probably require a bit of a dimple for clearance (thx @Daniel_Y for the measurements in ressources!), tire in this pic is 50mm wide and also probably a bit too close for comfort?

Excited to hear what you think! Oh and also, anyone in mainland europe ordering from paragon anytime soon? I may be in the market for a few things and shipping costs are less painful when shared!