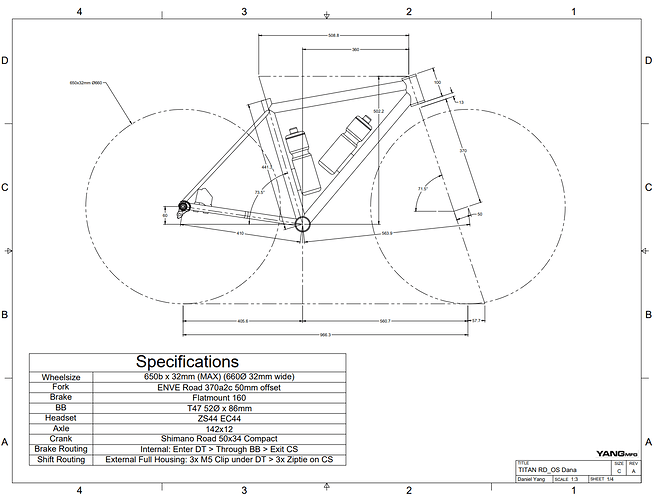

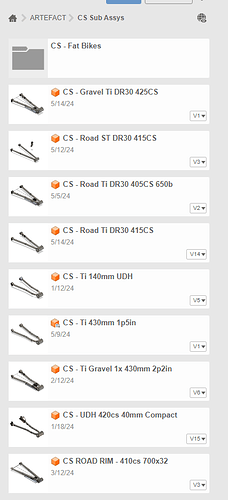

The chainstay sub assembly is the most important part of your custom frame design. It requires the most engineering to handle your drivetrain clearances, tire clearances, dropouts, brake standards, and bottom brackets. A well-engineered sub-assembly can be re-used for many different geometries and bike designs.

Step 1: Clearances

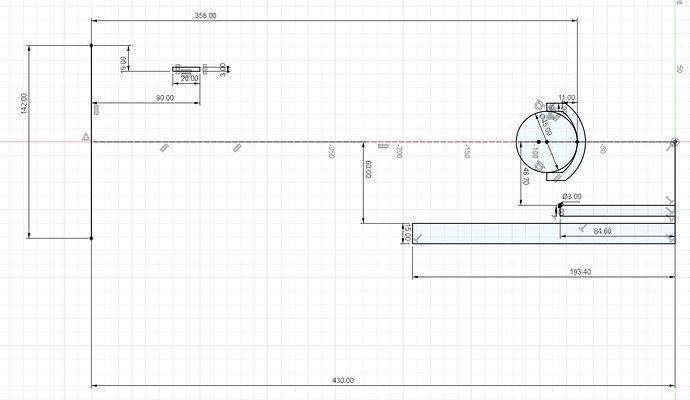

The clearance sketch is your base sketch. It is used to represent:

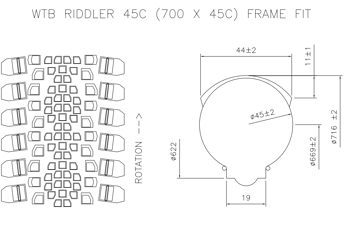

- tire clearances

- Drivetrain clearances [Standards] Road and Gravel Drivetrains - Cranks and BB's

- Axle spacing

- Chainstay length

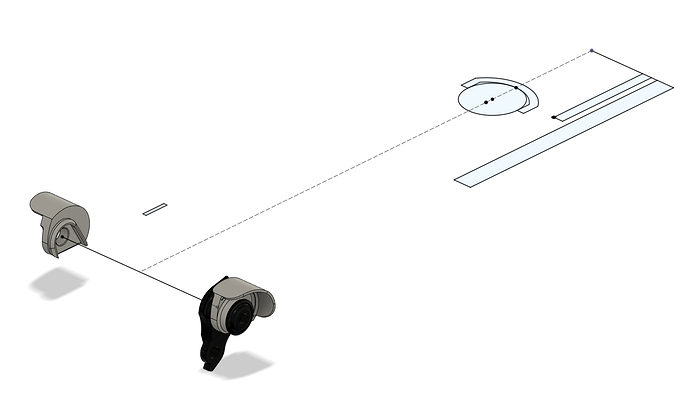

Step 2: Dropouts

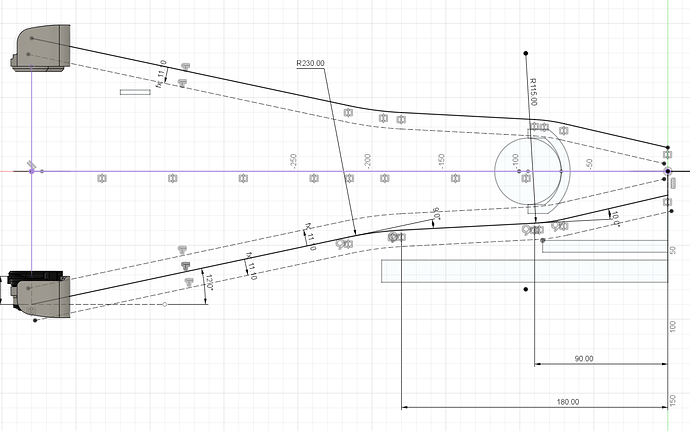

Join the dropouts to the clearance sketch. This allows you to visualize where the chainstay will land on the dropouts.

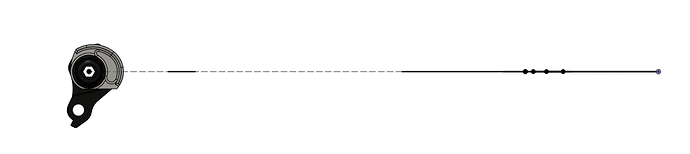

The dropout are clocked correctly if they flat is parallel with the virtual chainstay:

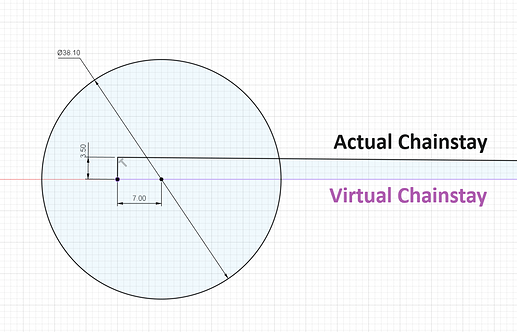

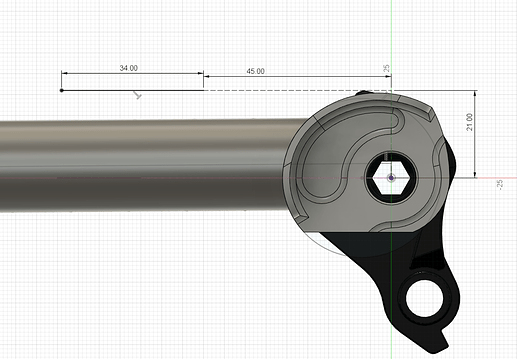

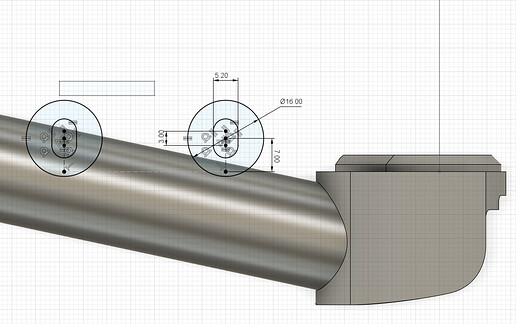

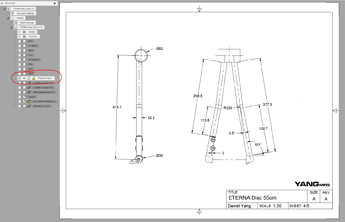

Step 3: BBDR Sketch (Bottom Bracket Dropout Sketch)

The BBDR sketch serves three purposes:

- locates the dropout hood

- draws the bottom bracket

- creates the “Actual Chainstay Plane”

Virtual Chainstay: the plane that intersects your axle center and BB center

Actual Chainstay: the plane that your physical chainstays are drawn on

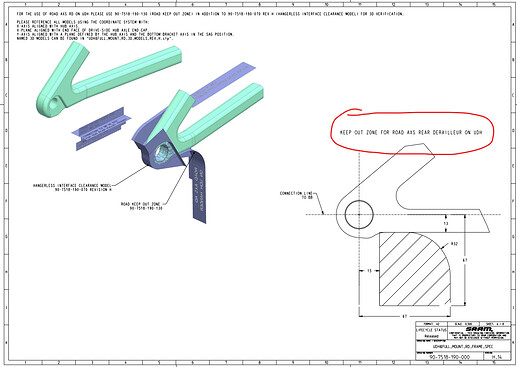

Note: in order to make UDH dropouts fully compliant, you need to offset the chainstay 3.5mm up

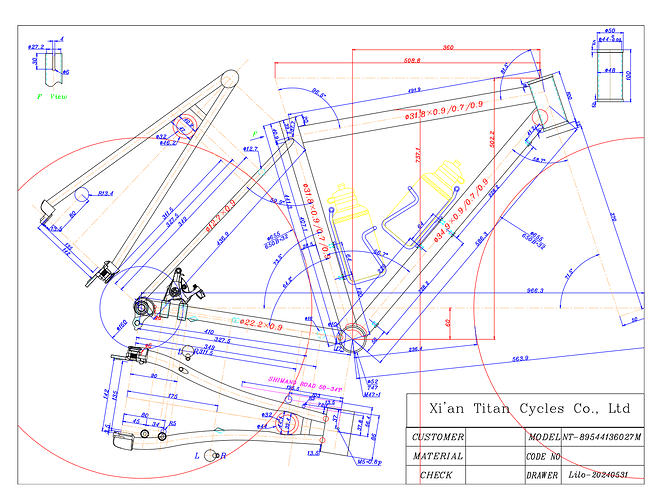

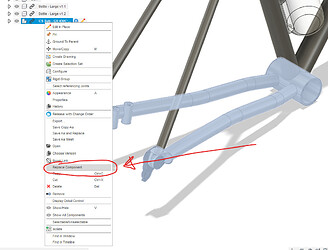

Step 4: Chainstay Centerlines

The purpose of this step is to draw the chainstay inorder to connect the dropouts to the bottom bracket while navigating the crank, tire, and chainring clearances. It takes a bit of art and experience to layout the chainstays. Here is the final solution:

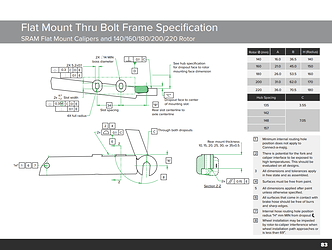

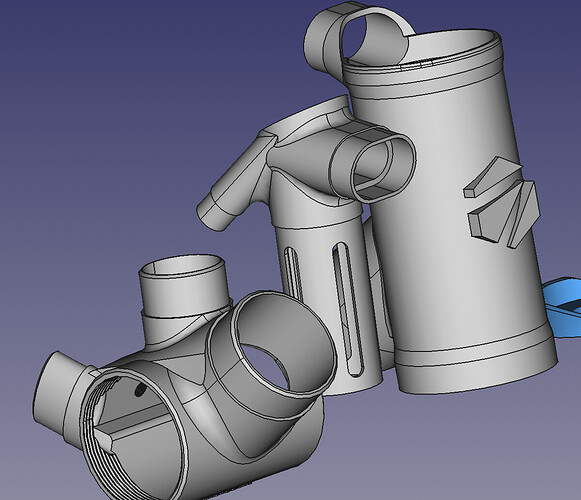

Step 5: Flatmount

DO NOT overlook this step. The flat-mount bosses are the least interesting, but they are the hardest part of the chainstay subassembly to get right. You need to figure out how to do it in CAD before you tackle them in real life.

From page 82 of the SRAM frame fit specifications:

First sketch locates the bosses:

Second sketch draws the bosses:

References:

Drivetrain Clearances: [Standards] Road and Gravel Drivetrains - Cranks and BB's

Flatmount Standards (page 82): https://www.sram.com/globalassets/document-hierarchy/frame-fit-specifications/road/2023-road-frame-fit-specifications-rev-c.pdf

Tire Body: