Chapeau. Ride the snot out of it.

thanks, I am! Every ride I told myself to take it easy, and every ride I ended up with some 2 wheel drifts into corners. And I am not skilled enough to ride like that ![]()

Why can I only “heart” this once?!?

Awesome stuff mate. Enjoy.

Only way to get skilled is to do it. Skin grews back. ![]()

I was invited to the skids and giggles podcast and we had a chat on the ups and downs of building my bike:

https://skidsandgiggles.com/podcast/ep82-reto-aebischer-afterlife/

life goals achieved: my bike on the front page of pinkbike ![]()

Big leagues when PB shares your build. Great stuff.

Congrats! This has been a sick project to follow and an inspirational one too!

Had some time on my hands and started with the CAD of an agressive short travel bike. should be light, should be “easy” to build leveraging CNC machining services and 3D printing, combined with geometries that are easy to manufacture with composites. But also needs to be sexy.

We will see where this goes…

Wow will be fun to watch this thread and see where the next one goes!

Woohoo Flexi times ahead

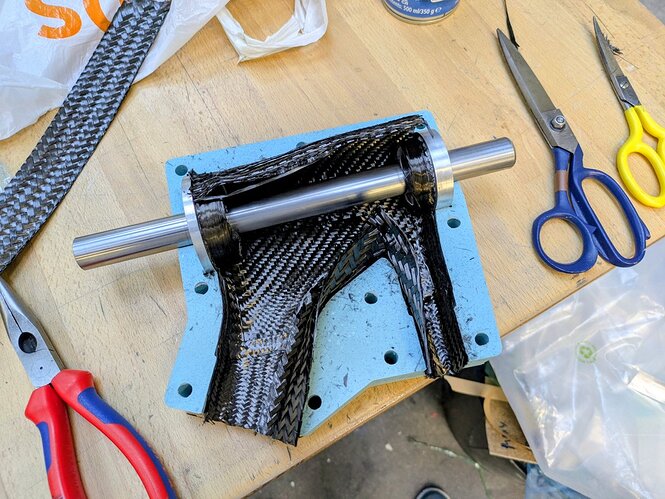

machined moulds for the chain stays and seat stays this weekend. Not that I am anywhere ready with the design, but just felt like making some chips…

bolted together. soo happy with the fit of the two halves, there is absolutely no wiggle with the slightest interference fit.

too shiny to really tell what’s going on. but a really simple design. Would have liked to make a much more fancy design, internally pressurized and heated, but decided to just get it done and make something simple.

1.5kg material removed. Not bad for a homemade CNC router.

pretty happy with where I am at with the design:

The shock mount needs some work, and the rear triangle needs routing for the brake hose. Other than that I am pretty much done. Simulation showed that I needed to beef up the rocker link. It’s substantially more solid now and visually looks still very light. gained a couple grams, but still very light and remained easy to machine.

over now - thanks everyone!

I promise you guys a write up, and a beer for everyone, but first please go to the mtbnews Instagram page and go vote for me!

Is there a website for voting or just the ‘gram?

Maybe I’ll ask the lady if she’ll vote on my behalf ![]()

So I finished my bike in time for this years craft bike days and I feel I can finally show it off here as well! I don’t really know what to tell you about it, but feel free to ask whatever you’re curious about!

It’s really an exercise in fabrication techniques and frame flex for the rear triangle. Love how it turned out, but didn’t ride it yet. Not properly at least…

What a bike!

As I told you earlier on your Insta, I’ve been honored to admire the bike in “person” at Craft Bike Days, but somehow failed to have a chat with you!

Mechanically similar to mine while aesthetically totally different!

Astounding work! Looks like forged carbon rear dropouts with flex points built in? The build quality is amazing. Did I miss travel and basic geometry figures somewhere?

Yeah flex pivot in the dropouts. Note that there is no chopped strand carbon in there tough.

- 125mm rear travel, 130mm front

- 475mm reach

- 430mm-ish chain stay length

- 65° head angle

- 78° seat tube angle

Thanks for sharing these images!

It looks like you made the ST,BB thing and HT with some 3D printed moulds right? Then bonded in the other main tubes later.

How did you do the TT and DT? Did you wrap a mandrel or cut moulds like in that chainstay(?) image?

Could you tell us a bit more about that anti chain slap device you made? Initially I would have guessed 3D printed TPU but there is some mould parts there. What’s going on?