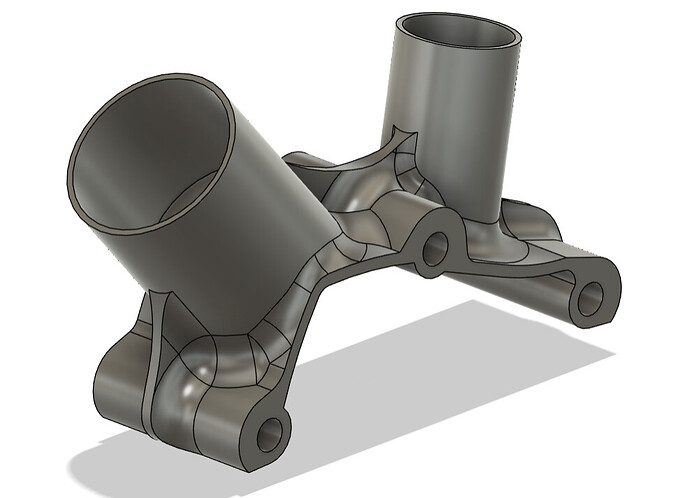

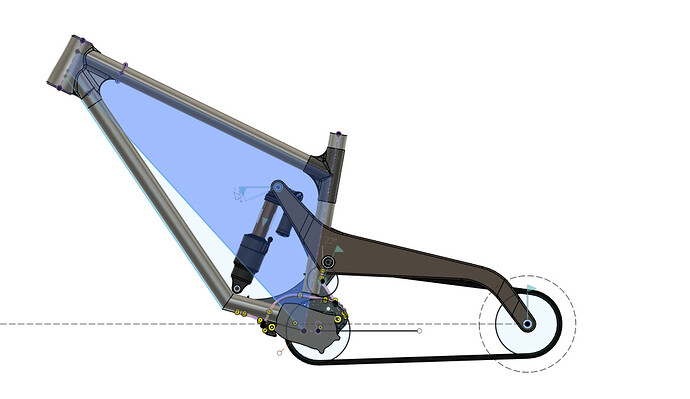

I have a Lahar! I’d like to make a longer front triangle one day.

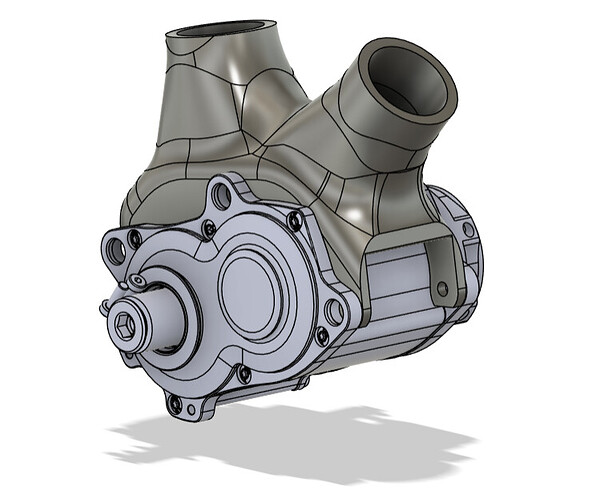

I’ve got a few lahar gearbox mount files if you need em… I’m still yet to ride one sadly

That would be great! Thanks!

Cam Cole used to come ride Champery and Morgins with us on his Lahar a long time ago. I’d love to try it with a longer front end.

I have a Zerode that I’d also like to make a new front end for.

I probably have some pictures of you riding… There’s a G2.5 in Aus that I need in my life… I may know someone with some rough cad depending on the bike… flick me a buzz and I’ll see what I can find

Really? From way back then?

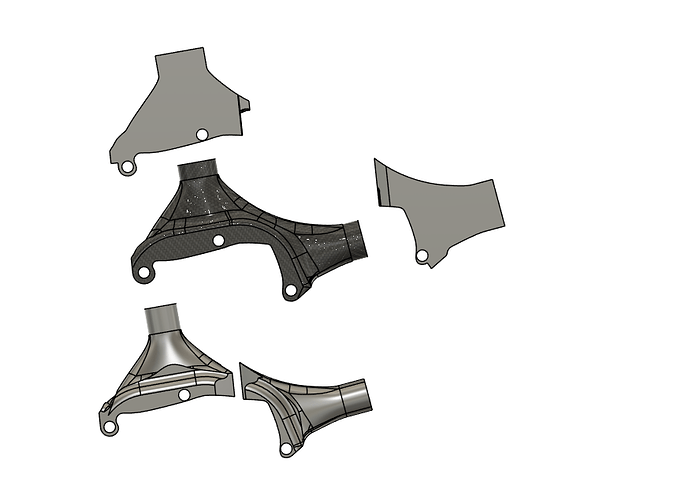

I’m looking forward to seeing your build! I have lots of carbon, epoxy and vacuum bagging materials from making snowboards. I’d love to try a bike!

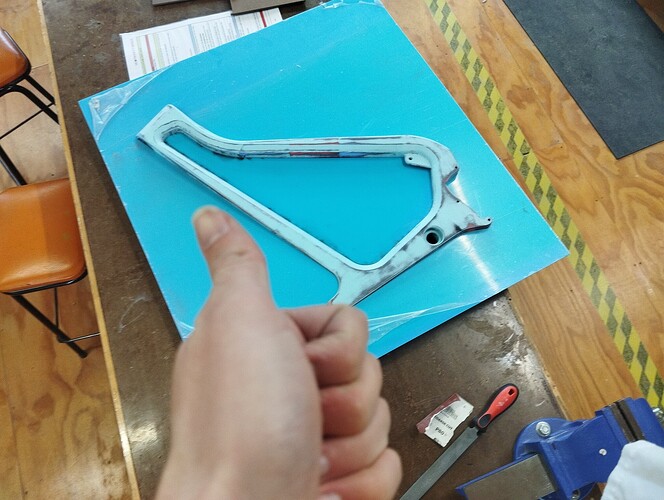

Dang. At first I thought that was some awesome distressed paint job.

Yeah it’s an awesome look, unfortunately I’m not quite talented enough to do it on purpose

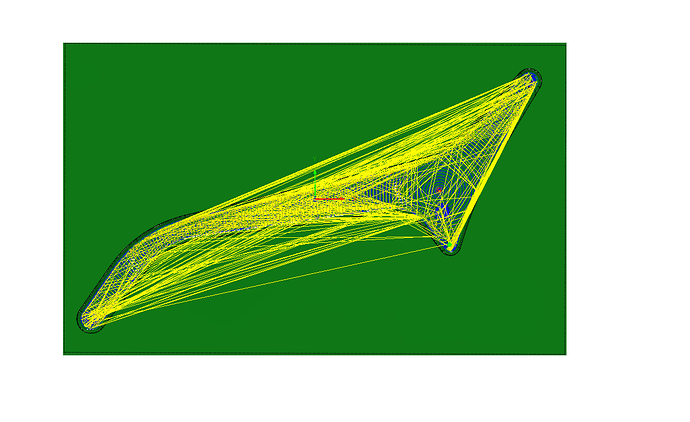

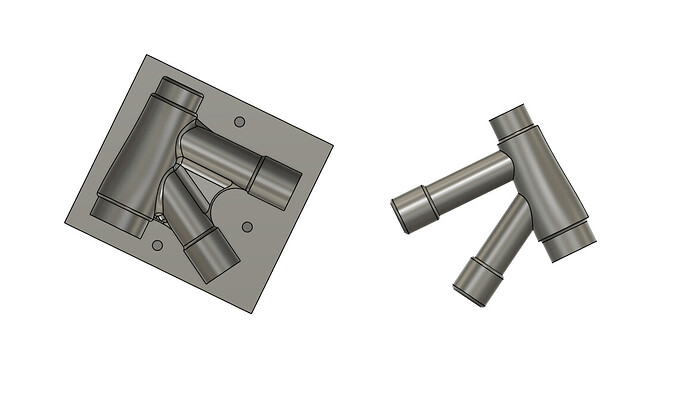

Not sure what’s going on in the picture. How is there all that fileting wax all over the place?

“Just” demoulding issues or is there more going on? What was the (paint) base on the plug, what demoulding agent did you use and what was the curing cycle of the paint and the mould?

I know the frustration all to well. But just take it as an opportunity to improve on things you would have changed already. You’ll get there!

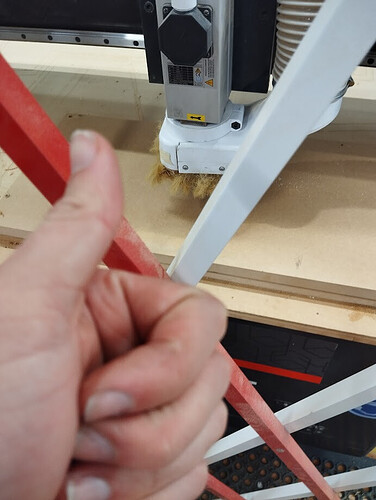

Not sure on the curing cycle of either tbh, but I left it for 3 odd days to cure so I assumed it’d be fine. I used a few coats of this mould release followed by 3 coats of pva, annoying but it is what it is and there are things that’d I’d deffo change anyway, when I get some time again I’ll CNC up the other mould and try crack out a swing arm

More fun to be had

Wow not quite sure how that happened when using PVA. That’s usually the fool proof method but you trade that for a worse surface finish and less accuracy as it builds up quite thick.

How was the PVA applied? Spray or a foam brush?

If you use 1k paint that can outgas for quite some time and cause all kinds of issues. My lazy method for 3d prints is usually bondo for the bigger stuff, then 1k spray filler from a can, and seal it with a 2k clear coat from a can and let that cure at the highest temperature your print allows for. Then after that just a chemical mould release and a waxy mould release. Had some very minor issues here and there where it just pulls a little paint off in some corners, but that’s then easily scratched off the negative mould.

Yeah I’m puzzled, similar method for mdf moulds?