Really interesting thread! I’m planning to “smoosh” my seatstays to create a flex point for a new frame build, similar to what Reeb does on the SST (thanks for showing this, @RxDesigns).

Smooshed Shape

My smooshed seatstay section is 5/8"x.035, 70mm long, with a 20mm transition between round and elliptical cross-sections at either end and 30mm of an elliptical cross-section in the middle.

I followed the approach Daniel describes in his dimpling write-up to use a constant cross-sectional circumference to size the elliptical shape. I wasn’t sure how much spring-back would occur (I’m using normalized tubing from Wick’s Aircraft) and under-sized the ellipse by about 1mm in height to 9mm x 21.4mm.

Modeling: I created circles at both ends of the smooshed section and used these sketches to create cylindrical surfaces. I repeated this for the elliptical shape in the middle. The transition sections are surface lofts between the cylindrical and elliptical surfaces with a tangency (G1) edge condition at both ends.

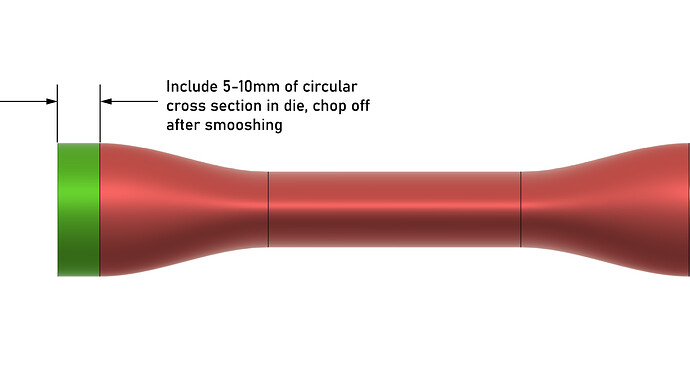

Die: The design for my smoosh die was inspired by Paragon’s tube blocks and a cool youtube video I found on a bolted chainstay press. There is a 1mm air gap between the upper and lower sections with 4, 0.5mm-tall pads that allow the die to bottom out when clamped. I subtracted the smooshed shape for the dies and machined the final design out of 6061.

Results

First, a picture of the die/press. The die has six bolt holes for clamping but my initial tests were done using a vise to press the two halves together (the hardware store wasn’t open in the morning when I tried this, lol).

Smooshed tube is shown below. The first attempt worked well - the small imperfections near the end of the tube were present before smooshing; I don’t think the tube sustained noticeable cosmetic damage while pressing.

The final elliptical section is 9.7mmx21.8mm (compared to the 9mmx21.4mm as designed). This lines up well with the assumption that the cross-sectional circumference stays relatively constant throughout the smoosh area (~51.3mm for the ellipse vs 49.9mm for the round section).

Oversights/Learnings

I didn’t add any locating features to align the two dies aside from the oversized bolt holes. I don’t think a lateral (side-side) locating feature is necessary - the two halves seem to self-align while being pressed. I should have added a longitudinal locating feature as the two halves were misaligned by 0.5-1mm during my test. I was originally worried about binding the die closing with an alignment feature; in retrospect, this isn’t a big concern.

The end of the tube flares out. Not a big problem, and something I can easily fix with a quick file or trip to the mill/lathe. If making the die again, I’d add a 5-10mm long circular entrance section and chop off the end of the tube after smooshing. Unfortunately, I’ve already ordered tubes from PTL cut to final length and can’t implement this change on my current project.

Overall, promising results and I’m eager to build a frame with this method. Fusion 360 file below for those interested.

Ovalizing Press v7.f3d (200.0 KB)