Looks great.

Usually, when it can’t shell, it means that there was a feature that is too small to create the offset face:

For example, these curves might be too small

Looks great.

Usually, when it can’t shell, it means that there was a feature that is too small to create the offset face:

For example, these curves might be too small

Got it! I had to adjust my fillets.

When dimensioning the male receiver for the chain stay tubes, do I need to make them slightly undersized to insure the tube will slip over them? What other steps are suggested prior to sending this in for a print? I greatly appreciate all the help!

Can you share the link to the part? I can look at the cross sections through the Fusion360 viewer.

Is this yoke to be brazed or welded? If it’s welded to a 19.05x.09 tube, I make the male nubs 1mm smaller (17.05 OD)

I put the yoke in my frame design sketch and, I’d like to pull the bridge towards the BB a bit more but, it keeps breaking my model. The fine tuning sure adds a layer of difficulty.

@Daniel_Y

I think you linked an older version, or maybe you are still working on it ![]() . Let me know when it’s ready to review. In general here are some tips I gave to Swood:

. Let me know when it’s ready to review. In general here are some tips I gave to Swood:

The 3D printer is very dumb. If you specify a hard corner, it will print a hard corner. Make sure you smooth all the internal corners:

Sharp edges can chip easily and can cause problems with your print. Consider adding a .1-.2mm fillet on this edge:

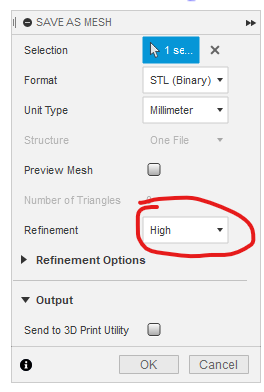

Finally, make sure you export the STL in high resolution. For some reason Fusion defaults to medium:

I have seen a few builders’ parts printed with a medium STL on accident, including mine ![]()

Here is some feedback on @maxwellkeegan design:

Overall, it’s nice and smooth and mostly self-supporting. There is only one critique I can give:

It goes from printing nothing (mostly support material) to a sudden solid layer in one layer. This will put a lot of heat into the thin walls.

If you printed it with supports, a tech would need to go in there with a rotary tool and grind out all the support material. It’s doable, but the fewer post-processing steps, the smaller the chance for mistakes.

This feature will print, but you need to ask yourself, what does it accomplish, and at what cost?

@Daniel_Y Would a transition from the wall to the flat face, maybe using a long fillet, be better?

Yup, that would help. It will print fine as-is probably 99.9% of the time (total guess), but the main question is still what is the value of this feature?

It’s easy to get carried away with the power of 3D printing, but…

I suppose I was getting greedy?! I figured a vent hole for purging would be beneficial. Should I remove the entire wall, or drill a vent hole manually?

If you removed the entire wall, the whole yoke vents itself? Or am I missing something?

Or by purging, do you mean you want to create a dam for the argon?

Hey @Daniel_Y! Could I get another set of eyes on this yoke design? Design intent is to clear a big ol fender over 48mm tires and gravel double chainrings. I set the thickness to 1.2mm which might be a touch on the small side? Let me know if that’s living on the edge.

Lib-Fab-Yoke-v2.f3d (465.8 KB)

Lib-Fab-Yoke-v2.step (367.2 KB)

edit: fixed a small issue

Looks great. The design is very smooth.

IMO overall thickness needs to be thicker. I won’t say a number because I really don’t know either ![]()

You can use the mechanical properties of stainless as a guide (I print with 316SS). For comparison, hardened chromoly data is here.

That’s great feedback, thank you! It’d be TIG’d. I’ll explore with thicker material - I was trying to get overall weight/$ down but went a bit aggressive on that…

Took your feedback into consideration - bumped up the overall wall thickness to 2mm, shortened the leg a bit, and reduced the thickness/length of the protrusion. I need to double check crank clearance still but it’s looking good! Mass is 91g which at $1/g is not so bad all considered.

Lib-Fab-Yoke-v3.step (327.5 KB)

Lib-Fab-Yoke-v3.f3d (520.2 KB)

An interesting comparison - here is the yoke I’m working on (pink) alongside the Lichen gravel yoke (orange) which I had originally designed this frame around.

LGTM, you can DM me with the final version if you are ready to print it.

IMO, the cost savings of 3D printing really come from manufacturing time savings rather than material optimization.

Although it’s kinda a catch-22:

In the end, I wouldn’t play the material optimization game on 3D printed parts unless I had serious lab testing and QC controls to back it up (then that adds to the cost).

To reduce cost, I focus on shortening the overall length. That is a win-win:

@liberationfab Is this a welded-in CS bridge in your design? If it is, it is probably worth considering whether it is necessary (is it supposed to increase stiffness?) as it will create a stress concentration in the yoke and may ultimately lead to premature failure of the component. Both PVD and Kris Henry have shared failures of 316SS yokes relatively early in their ride testing due at least in part to stress concentration features near the BB.

PVD example, thick to thin with virtually no radius:

Here’s a link to his write-up: http://www.peterverdone.com/fail-early-and-often/

I can’t remember if he identified the same issue as I’m pointing out (I recall some discussion of wall thickness), but geometry talks.

44 Bikes example, thin extension to stiff box section:

And a link to Kris’s write-up: https://www.44bikes.com/builds/snakedriver-v3-development/

That’s really good stuff to think about! The bridge is just for fender mounting - it’s some 1/2" tube that I usually silver braze on. I see how it could cause some additional stress in the part as it’s torqued through pedaling.

This will be a big experiment for me! I will probably throw the 3DP yoke on my personal beta test frame and ship the Lichen CNC’d yoke with at least the first few customer frames. It’s for a road bike so hoping to avoid some of the stressors that PVD & Kris ran into.

I am curious what wall thickness those folks were using. No one seems to want to put a number down, but I’m sure that has a big impact, especially if they’re suspecting issues with voids/bonding.

I think both of those yoke designs have some inherent stress risers (obviously after the fact now) that I would not have been designing in teh first place. (again, easy to say after the fact) They don’t look right to my eye and you avoid abrupt angle and section changes as much as possible.

In that last section view you will stiffen that chain stay section up and there will be two things going on. One is the side walls of the yoke and bent chain stay will flex, so you’ll get localised stress in the structure the second is both sides will be bending at that point…or the stresses from bending will radiate from that point. Personally I think so long as you put a nice fillet in there and have a good blend between the components you’ll be ok. Another option is to just attach the guard mount to one side and not join the two stays together. You could even make that part of the 3d print.