hi all, first post here! i have a silly question and i hope it’s not too ridiculous.

i’ve done some light frame modding now, brazing on disc tabs and bottle cage mounts to old steel frames, etc, but i’m curious about taking it further.

would it be worth the time/effort to take an old steel frame, say the old rockhopper sitting in my closet, and put it in a jig and replacing the 1" head tube with an 1 1/8" tube, adjust the ht angle, maybe adding a gusset or two, replacing dropouts, etc. mostly as a learning experience in fillet brazing as well as making the frame more useful for what i want out of it?

or would it be better to just buy a stack of tubes and build something from scratch?

my main goal here is to get better with my brazing but i also love the idea of taking an old frame and adjusting the geo to work for me.

some insight on what i want out of this project - i play bike polo and i prefer to use 26" wheels vs 700c. a lot of players will use track bike frames for the aggressive geo and replace the fork with one with a disc tab (we primarily play on single speed bikes with only a front brake) but most of what you’ll find out there is 700c.

there are some companies out there selling 26" track geo frames specifically for polo but they are either expensive, or known to break, or both in some cases. 26" steel mountain bikes are everywhere and can be had for next to nothing but the geometry is all wrong for polo.

is modifying a frame in this way a viable way to gain experience as well as end up with a unique bike polo frame, or is it a fool’s errand that will just leave me with wasted time and a ruined rockhopper?

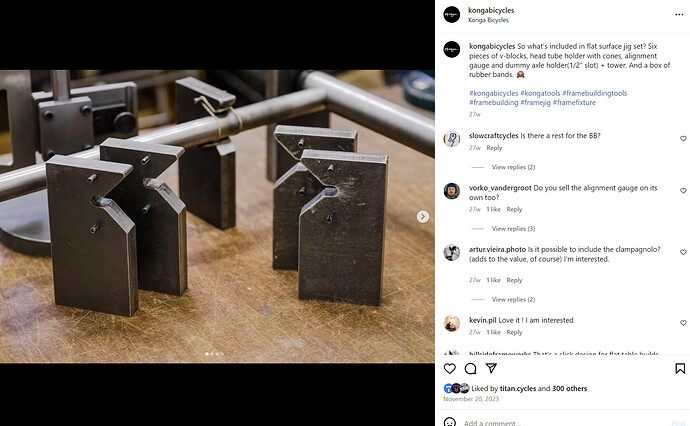

some other considerations - i don’t own all of the tools needed, reamers, taps, etc. which might be a point from building from scratch and towards modifying an existing frame. i do have a 1" headtube reamer that i believe i can source the 1 1/8" cutting parts for, but that’s kinda it at the moment. whatever route i take i will be picking up a frame jig.

thank you for any insight!