Check out Paul Brodie’s videos. He’s got some clever rear triangle fixtures that are much simpler than a full frame jig.

i have devoured brodie’s videos over the years haha. i definitely should go back and revisit them though, thanks!

I’ve done some minor mods of older steel frames as well. Totally worth doing and a great way to keep old bikes on the road (or trail). The flat surface fixture is the simplest and most flexible for your purposes and the tubing blocks can be re-used in the future for clocking the tubes for mitering. A basic 80/20 fixture is also not too expensive and there are many designs out there. But most would require some parts to be machined on a lathe.

I vote flat surface and tubing blocks. Too bad your in New Mexico, I have one I could loan you if you were closer.

-Jon

Oh, and www.geometrygeeks.bike is a good source for geometry info. But buyer be ware, it is user generated so may not be super accurate. One thing you could do is buy a cheap digital angle finder, that way you can get relative angle for all the tubes. Or put some wheels and tires on it and get actual angles. From there you can figure out miter angles too.

-Jon

my cheap digital angle finder showed up in the mail today actually! i picked up a miter jig for my drill and while it’s a pretty solid piece, it’s angle scale leaves lot to be desired. i figured the best fix was a digital angle finder.

the more i think about it, the more i agree a flat surface fixture might be the way to go. my biggest hold up is space, my shed is 10x10 and some of the space has to double as storage so it’s gonna be tight but i think i might be able to make it work.

i’m insulating the shed this weekend and putting a sun shade over it to hopefully cool it down in there. currently it’s an oven when the sun’s up!

do ya’ll think a torsion box workbench will work well as a flat surface, this plus a tube block set? it would take up a good chunk of my 10x10 shed, but it could double as my general work bench/desk for the other stuff i’m planning on doing in there.

i’m having a hard time finding anything local, i had considered building my own bench and using a t slot top, like this one from rockler - https://www.rockler.com/rockler-t-track-table-top-28-x-40

but that top alone cost more than this torsion box bench.

currently still working on getting the shed to be less of an oven when the sun’s out.

I think it’s good enough. +/-3mm of frame flatness is as much as you can expect without investing thousands into a professional setup. If you have good fabrication skills, you don’t need a certified flat table to get a tighter tolerance.

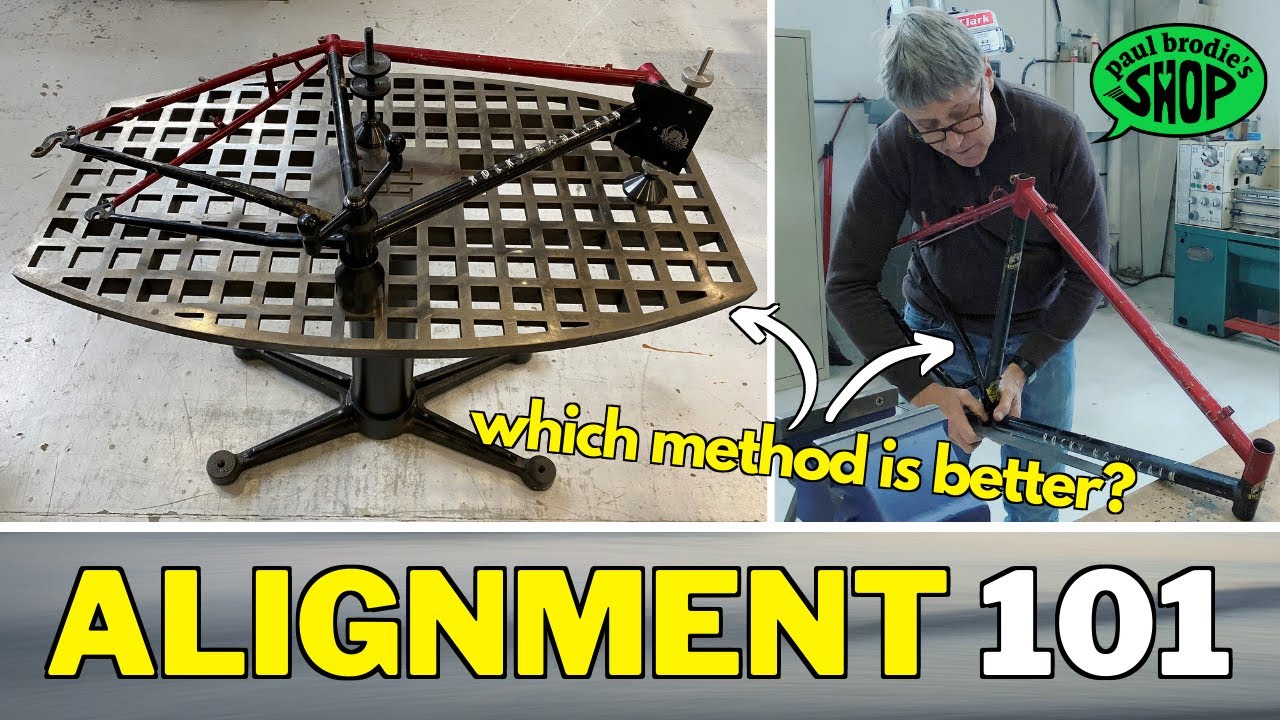

This video from Paul Brodie does a good job showing two different methods of allignment:

The surface table and the feeler gauge had different results, which probably means both methods are inaccurate.

Where are you located @floppywonka ?

i’m in santa fe, new mexico.

the torsion bench i was looking at sold shortly after i asked about it so i’m gonna keep looking for now.

i really need to go through brodie’s videos again, the man is such a wealth of knowledge.

ok, it’s been a sec but i just picked up a bench that i think, once leveled, may work for a flat surface w/tube blocks kinda setup. at least well enough to get me going on modifying some frames. it’s got a particle board top currently but i have some nice 3/4" thick proper plywood at work i’m gonna use to make a new top at some point.

i have a question, maybe i should wait to cross this bridge when i get there, but i’m curious what you guys would do. if i’m shortening the chainstays on a frame by quite a bit, like from 455mm to 360mm, the original seatstays are gonna be just hangin out in the air behind the dropouts.

i want to reuse them, and i would like to avoid removing them completely and reattaching them at the seat post collar. but if that’s my only choice i guess i’ll do it.

would it be possible to bend the stays while still attached to the rest of the frame? either in an arch, or maybe give them a bit of a dogleg kinda kink? or, if they aren’t THAT far away, maybe adding some plate to the top of the dropout to meet the seatstay at its original location?

i know none of those options are really all that ideal but in the end this will be a polo bike and it doesn’t need to be a beauty queen haha.

Nice shop!

I think the best solution is to bend the stays downward to meet the new dropout. However it looks like you have a double tapered SS, which will make that more challenging. The bender die needs to be on the constant diameter section.

Are you removing the cantilever posts? If so, you may have enough room to get a bender onto the straight section of the tube.

i wasn’t planning on removing the posts but they are unneeded and if it would make my life easier i’ll do it haha

well, i did it. i ordered a benchmark 1.1 fixture.

still not sure if it was the best move or not but i feel like it was a crap-or-get-off-the-pot moment for me and i’m glad i went through with it haha.

once it’s here and set up i’ll post a pic or two and try to keep this post updated with how my journey into frame modifications goes. i’m excited!

Big moves! Its always a risk to do something new. But you never make progress without taking some risk.

I have the benchmark, it’s a pretty easy fixture with small quirks. Once you get it setup I’d be happy to chat with you about it.

it has arrived! can’t wait to get it home and put it together.

i need to work out how to mount it to my bike stand, or maybe my work bench, or maybe build a stand for it. i have a pile of 2x4 sitting in the shed i could probably come up with something.

i’m excited!

Great thread. I’ve been thinking of radically modifying an Eriksen frame… though I am still not sure it’s worth the effort and expense compared to building a new frame from scratch…

i got it together! i definitely need to come up with a way to mount it to my stand, or make it its own stand. i built it clamped to my partner’s clay working table but i don’t think i’ll be able to clamp it to my work bench in the shed.

also, the dummy axle that came with it is 142mm, which is no good for me. gotta get a 135 axle for it.

i can’t wait to get set up out in the shed though! it should be a productive winter!

i’m looking at pmw’s dummy axles, they have an “exact” 135 and a normal? 135 that actually measures 137mm. since i’m working in steel, does it make sense to just get the “normal” 137mm dummy axle?

Yes, since you don’t want the rear triangle to be undersized. It would make inserting the rear wheel very difficult ![]()

1mm of wiggle room each side makes it a lot easier and those 2mm can easily be squeezed together with a QR skewer

The reason the axle is 137mm wide is that typically, when welding the chainstays, they pull in toward the center of the frame resulting in a narrower than desired dropout spacing.

In other words, using a 135mm axle would result in a frame with something closer to 133mm dropout spacing.

Widening the axle to 137mm will result in dropout spacing much closer to 135mm after welding.

Good luck,

KP