i ran out of gas again a couple weeks ago and haven’t been to get more yet. i’m going through it quicker than i thought i would, maybe i’m using too much?

got the back half of the 2nd frame, an old straight gauge gt frame, mostly tacked up. still need to do the drive side chain stay, but it’s the tricky one with the yolk plate. ended up picking up a tiny little wire feed welder during harbor freight’s week long black friday sale to do tiny tacks with to help keep everything in place.

have a head tube on the way to get the front end in shape.

i’m also starting on building a fork jig. i haven’t seen one at a price point that makes sense to me for what i’m doing, so i guess i’ll have to make my own!

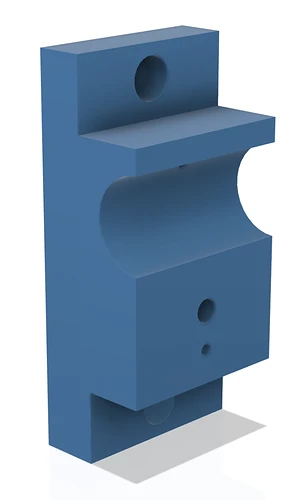

the dummy axle block is the tricky part, the rest is basically gonna be 15 series extrusions. i modeled a few different da blocks but since i’ll be having pcbway machine it for me i ended up with something that’s super simple to keep cost down.

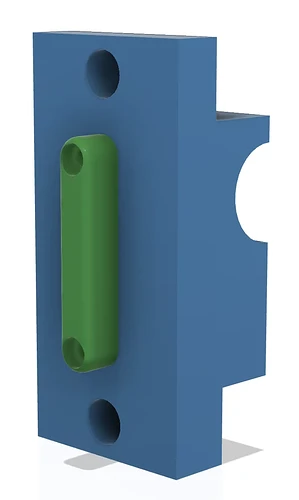

the green bit on the back i’ll 3d print, it’s meant to sit in the slot on the extrusion to keep it square. i don’t think there should be enough heat getting that far into the fixture for it being made of plastic to be a problem. i’ll have to tap the two m3 holes for that myself, which might be tricky.

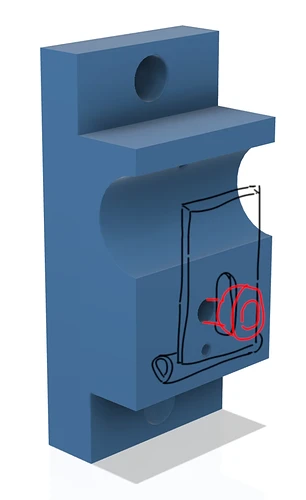

the clampy bit i’ll make from 4130 left over from a rack i made a while ago, and an m6 cap head bolt will do the clamping. i’ll have to tap that hole also, which i’m not looking forward to. something like this -

it’ll bolt to the extrusion with a couple m8 bolts and t nuts. i’ll scribe some center lines on it to help with setting it up and i think it should work?

the extrusions and other bits i’ll probably get from 8020.net, they seem to have the best prices from what i’ve seen.

that’s where i’m at! still surprised by how quickly i’m going through the gas. maybe i should look into going to bigger tanks? or maybe do more pondering on switching to propane.