I got a notification that I’ve been a member of this forum for a year but I’ve never properly introduced myself.

My name is Johnmark. I’m a mechanical engineer currently living in Cleveland Ohio. I started mountain biking but eventually branched out into road biking and touring. The idea of building a frame was bouncing around in my head for a long time. A year ago decided to take the plunge. I bought a book about lugged frame building and started absorbing all the info I could online. My first post here was asking for advice on silver brazing. This forum is the most active and informative frame building community I’ve found and it’s been an invaluable resource for me as a ‘self taught’ (nobody is really self taught…) hobby frame builder. On a side note, frame building is a very niche activity both as a profession and hobby, which fosters a community where pros and hobbyists intermingle. I think that’s really cool and is something I’ve never experienced, or even heard of in a community before. It’s like Micheal phelps giving me advice on how to tread water.

Anyway, here are some photos of my journey as a ‘maker’ and a cyclist.

My first real bike as an adult. Sold to me by a coworker for very cheap. The second pic was it’s final form before I retired it.

The bike I toured across the US on. I learned a lot about bike geo and fitment with this one. It was originally a cheap schwinn hybrid. This bike also had my first “custom” part made using a kind stranger’s drill press mid tour after my hose clamp rack mount’s started getting loose.

Some more early custom bike parts.

I sewed these bags myself. The frame bag wasn’t turgid enough, hence the duct tape in the second pic to stop it from bulging out against my legs. I haven’t sewn in a long time. Maybe someday I will re-visit that.

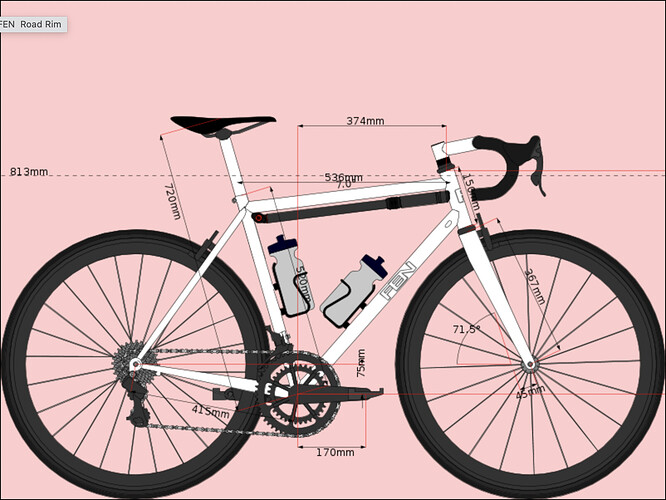

My first frame build. Built about a year ago. It’s far from perfect. There’s things I would change, but I’m still very proud to have done this. At the time of this post it is my most ridden bike. I ride it several times a week at least. I call it the Guppy.

A custom top load stem.

Second frame build. A pretty big step up in difficulty from my first frame. This bike met and surpassed all my expectations. It’s long, heavy, and an absolute seld downhill and up steep climbs. I call it the Hog.

Third frame coming soon! This one is a gravel bike. I might stick with the animal names and call it the Goose.

I don’t know what my future as a hobby framebuilder will look like. After this gravel bike I will have three bikes, which is all the bikes I need and have the space for. I may start iterating on my existing frames or start making components. I’m also at the point where I think I would be willing to make a frame for a friend. Either way, I really enjoy this craft and I’m glad to be a student of framebuilding