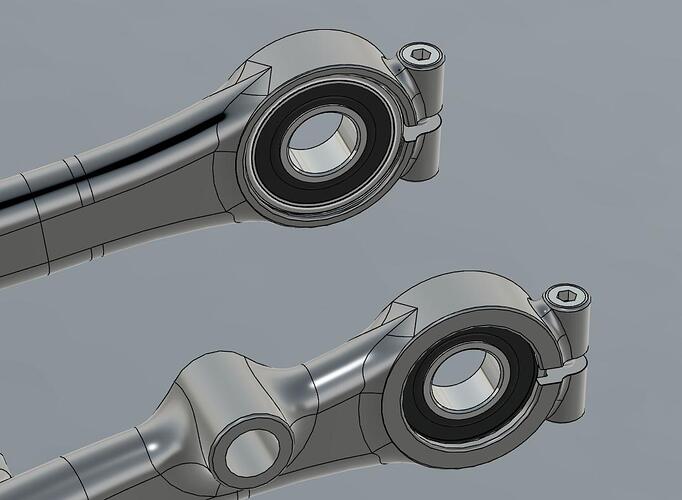

All my fillets have been chorded, only a few necessary radius ones remain!

Could you give me the file for the UDH dropout for the drive side? I can’t find it anywhere…

It’s available to download here:

https://universalderailleurhanger.com/

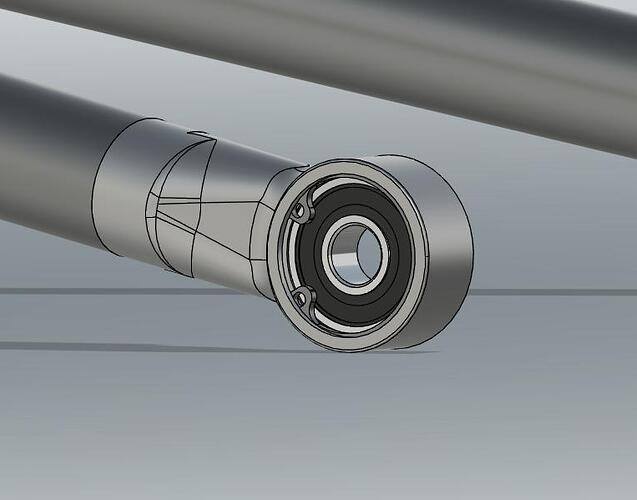

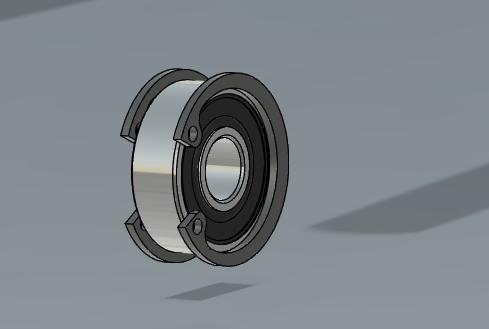

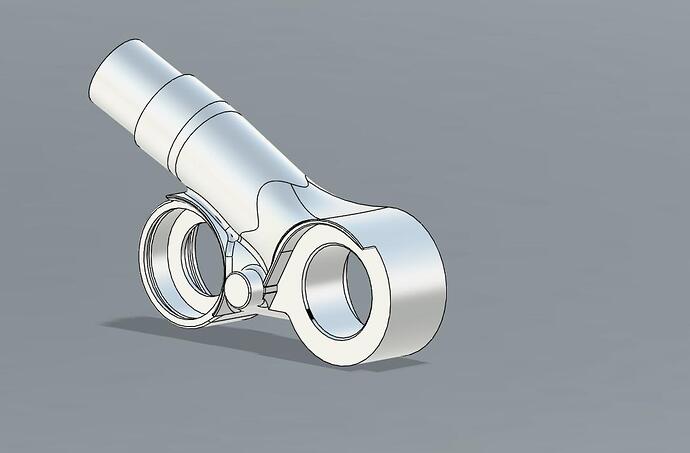

Not for anything I’m looking to make at the moment, but I’ve made a yoke. It fits two 8x16x5 bearings and increases the eye to eye of a shock by either 14mm or 20mm depending on flip chip orientation. If you have a 205x65 bike you could use it to fit a 185x55 shock.

The max static load on this bearing size (688 llu max) is 932N according to enduro bearings. Not nearly enough to handle the forces on a shock at bottom out.

Correct, I should use 608 Instead of 688 bearings

Sad times, 608 wont fit, so it’ll have to be boring old shock tunnels rather than bearings.

Yeah half decently sized bearings take up a lot of real estate and weight. Two 6001 llu max bearings would probably be best. My current design uses two 6900 llu max which are definitely on the light side as well.

Then there is always the option of some polymer bushings, which use way less space and in my opinion have a reputation that is not entirely fair. I think if designed properly they are amazing.

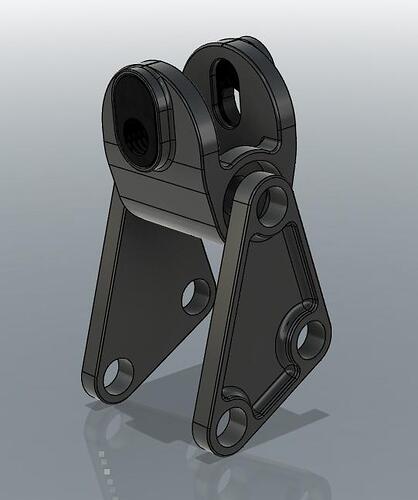

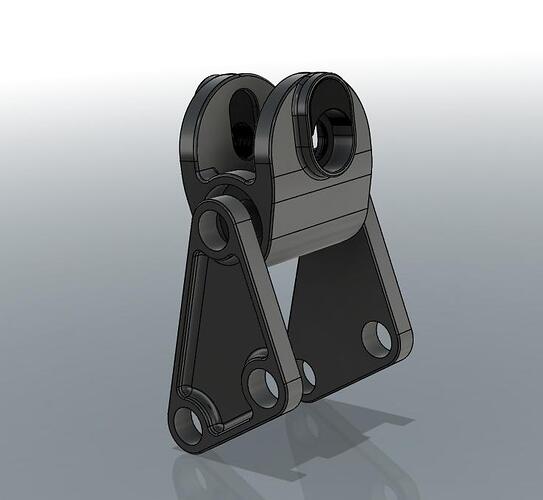

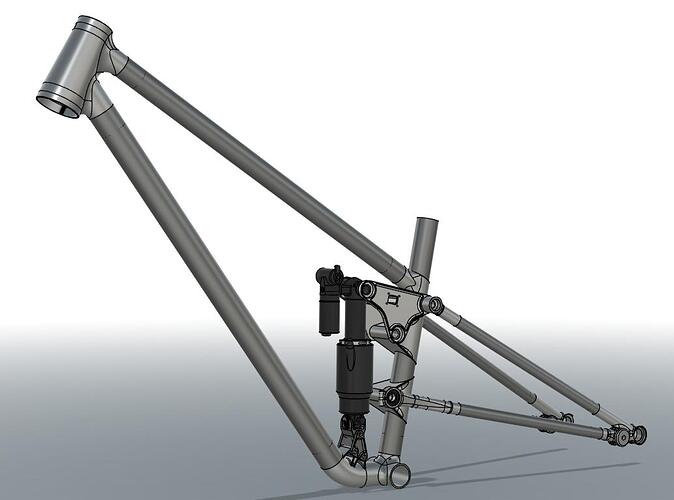

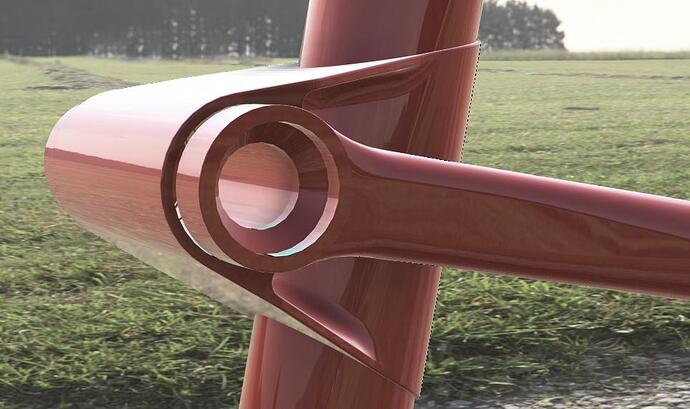

I’m calling this one the Comet Lite. It’s just a 4-bar Comet, some fun features include:

- Circlips for bearing retention on the chainstay

- Pinch bolt for bearing retention on the main pivot

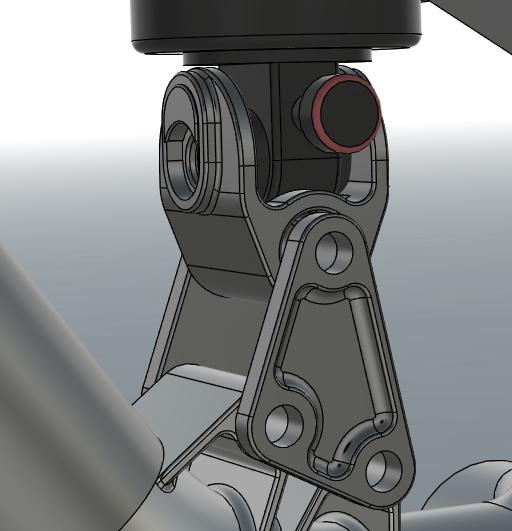

- Removable shock yoke for multiple travel modes (225x75, 203mm Mx / 205x65, 180mm 29"& Mx)

It only has one rocker link, and needs only 7 tubes. So it cuts down on material procurement.

I did not realize your yoke was on this end of the shock. There the pivot motion is only a couple degrees throughout the travel. In my opinion an igus bushing is the way to go.

Also, are you shure the chain clears your drive side chainstay?

It’s way up on an 18T idler pulley, I could model it but I don’t know the clearances at the moment.

What’s the reason for the shock mount under the yoke being a separate piece instead of being integrated into the frame?

This is just how I do them, I could always integrate it into the frame but I just do them as interchangeable links for some reason. I probably don’t have to, but if I ever have clearance issues or want to change leverage IRL with them, a modular design means I only have to change these pieces rather than making a whole frame.

I’ve got some news. I bought some tubes from a friend.

I’ve also made an updated model of the Dipper, in steel and 4-Bar, calling it the Dipper Lite.

It has some neat features, it’s compatible with all the pivot hardware from my Vitus, and uses circlips to keep the bearings in place like the Comet Lite.

Here it is rendered with some paint.

I’m going to look into getting more tubing soon, hopefully I can get my friend to make me some test prints and I can do some test fitting.

I’ve made a brazing/welding compatible model, it’s nice to have these kinds of things in the arsenal so I have a version ready no matter what I decide to do

Not gonna lie, I’m losing my mind a little waiting to have the bike in my hands. Every model I make is a cheaper method of manufacture than the last.

Haha I feel ya. Waiting on the right parts (lugs in my case) to come back in stock is killing me and I spent half of my ride to work daydreaming about the frames I’m going to build ![]() I envy all those who already know what it’s like to ride a frame that they made with their own hands.

I envy all those who already know what it’s like to ride a frame that they made with their own hands.

Good news is, I’ve got some plastic test prints ready to muck around with!

That is starting to look really refined now. Good job.

Thank you! As you can probably see, I’ve taken a bit of inspiration from your builds!

Haha. I noticed but it’s cool to see others appreciate what I’ve done on my builds. Looks good.