Hey there,

my name is Levin, I love bikes and I am a metalworker from Germany and my boss is kind enough to let me use the workshop in my leisure time.

I really enjoy reading the forum and I want to show some of the stuff I have build over the years.

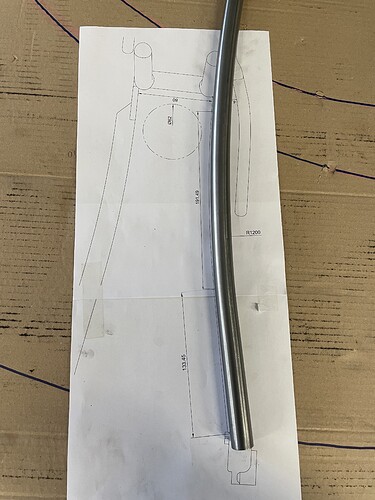

I started off by building small bike parts like top caps or this truing stand

After learning how to tig weld I was captivated by framebuilding and wanted to build my own bike.

The first frame I worked on was just a modification for a friend of my boss. The bike looks rather ugly and the top tube is the push handle from an emergency exit.

The first real frame I have build is a dirt jumper for my self. It was a lot of work but I enjoyed the process and learned a lot. I love how the frame rides and how well it holds up.

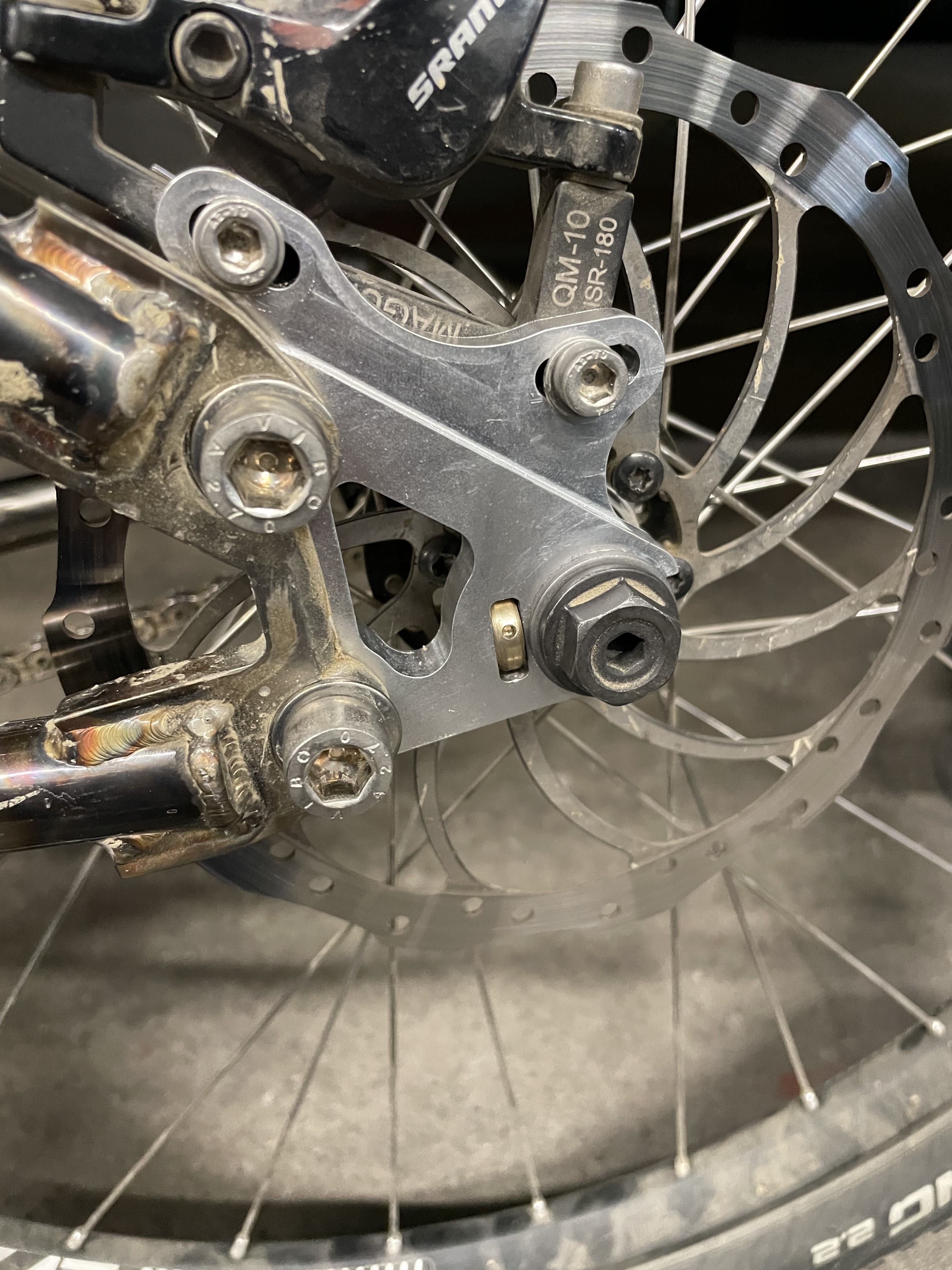

What I didn‘t like is that i had to use a chain tensioner. Fortunately I could cnc some new horizontal drop outs with build in chain tensioners.

After some time I wanted to build a new bike and friends brought up the idea of building a 24“ dirt jumper.

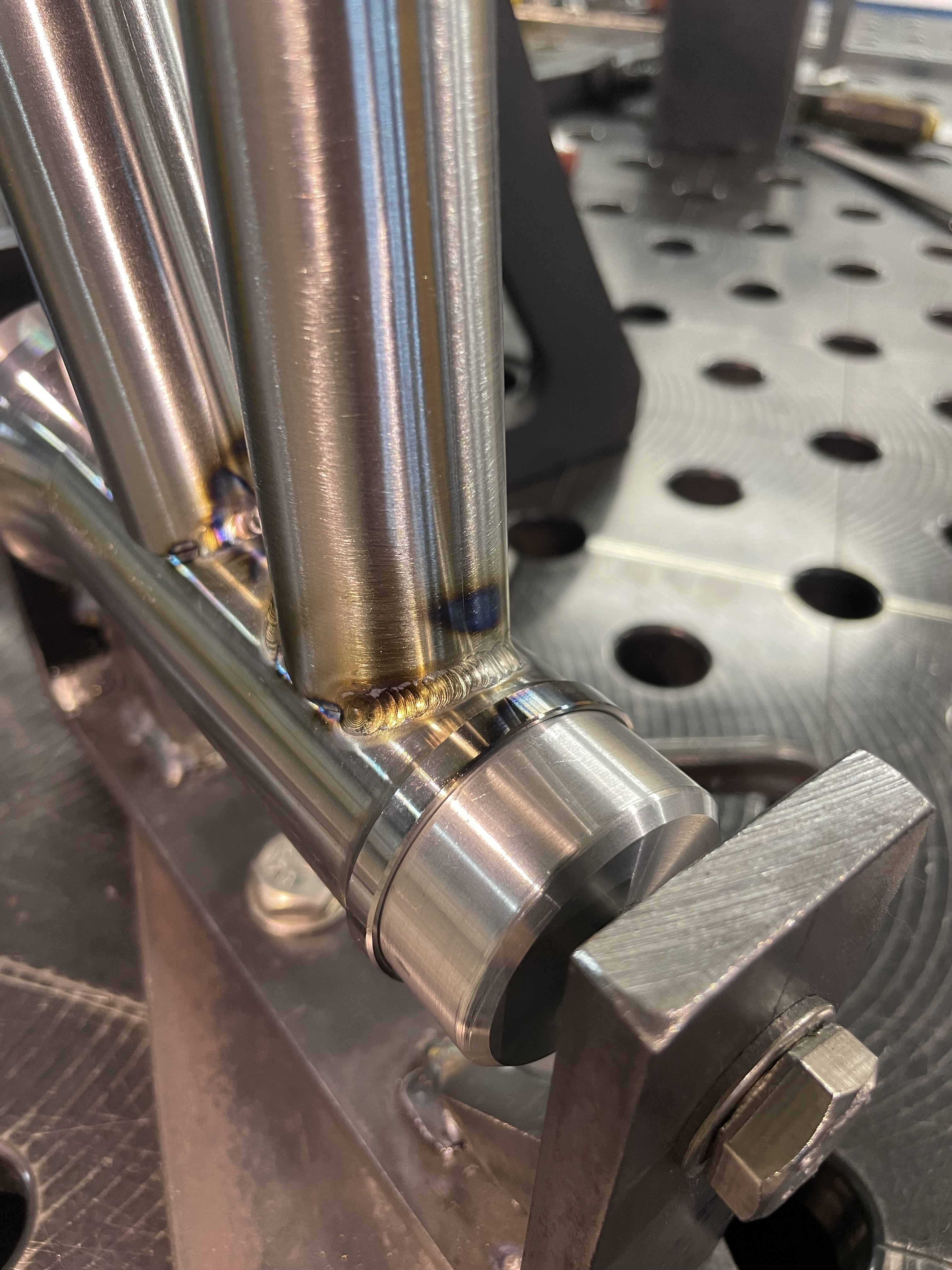

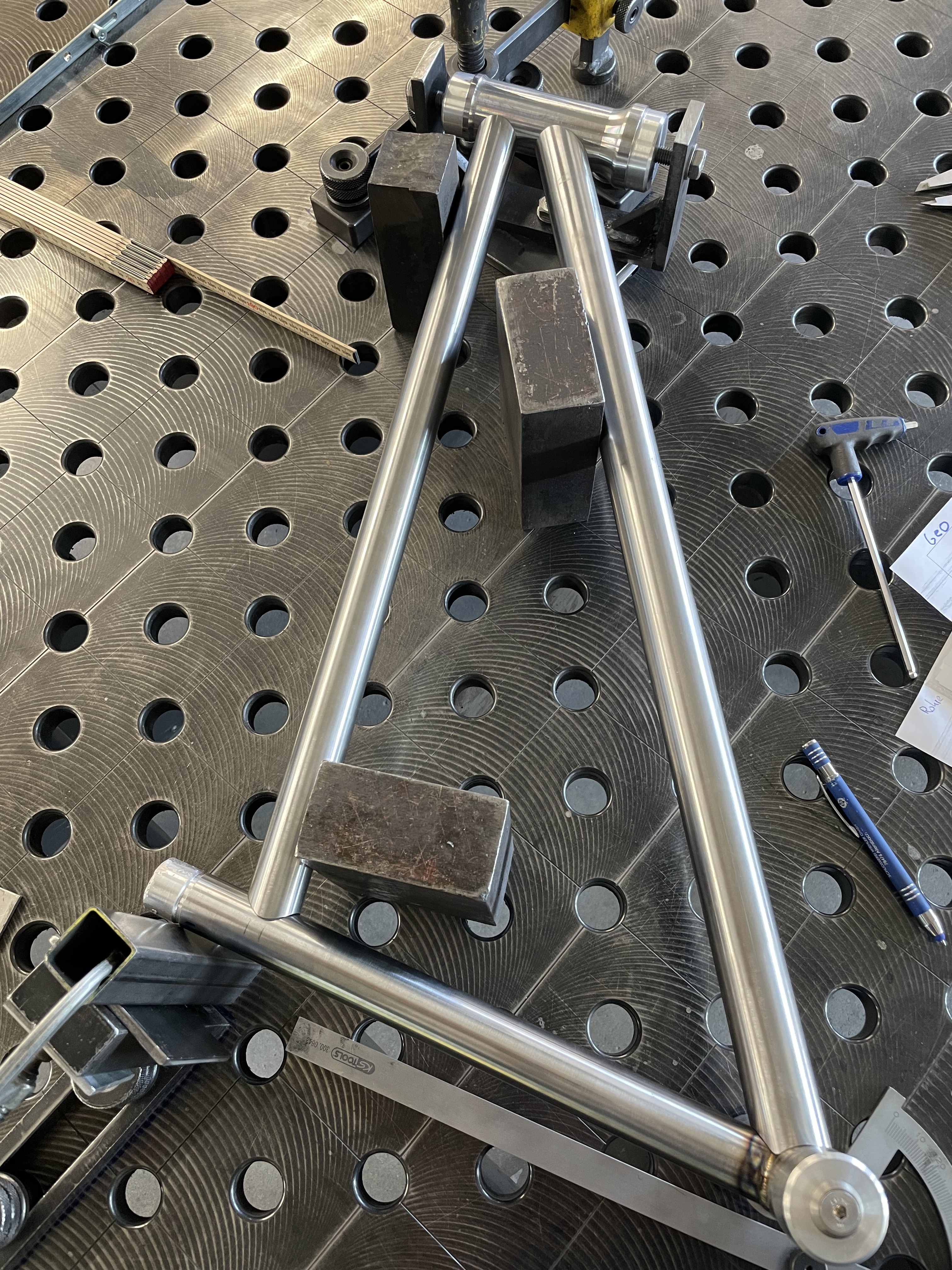

For the new frame I used another welding set up wich worked way better than the old one.

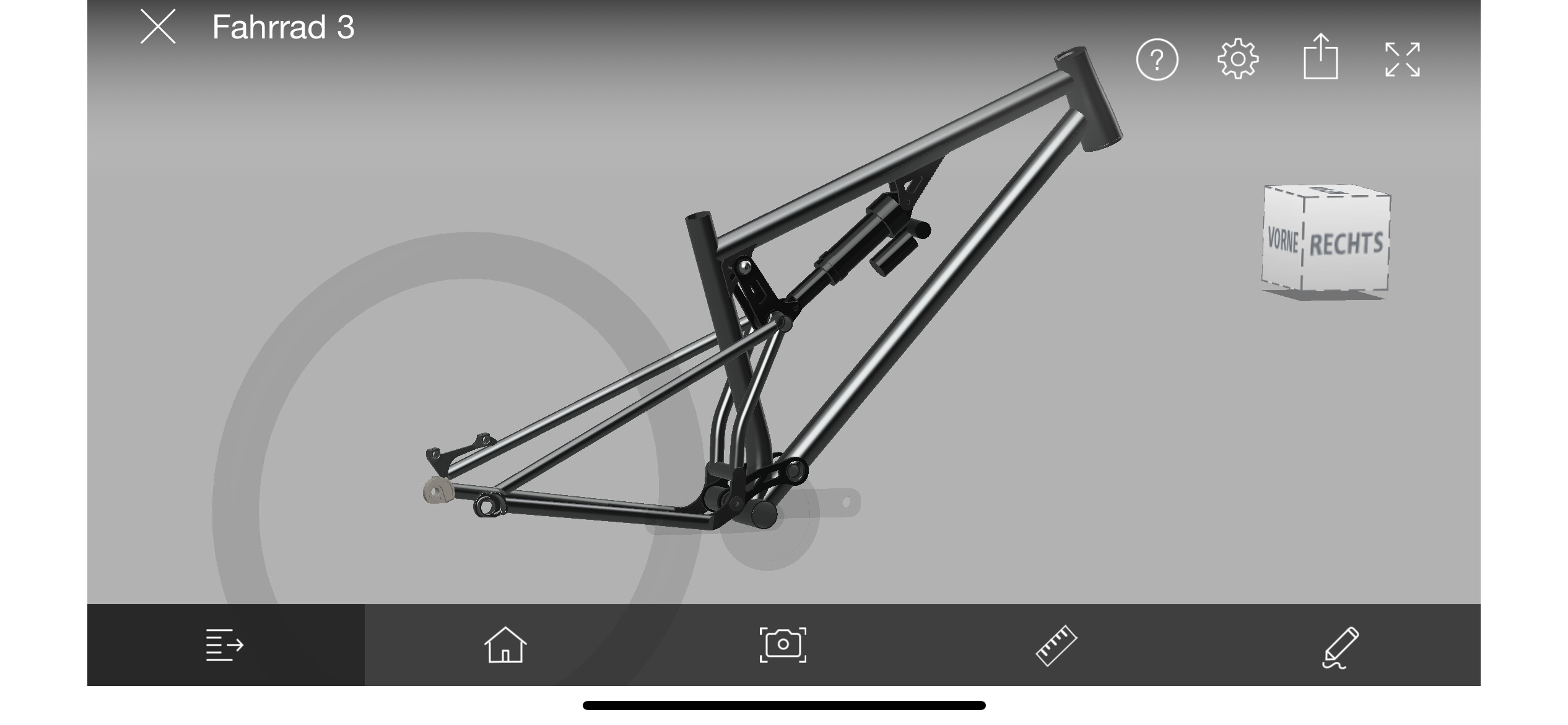

I modeld the frame in Fusion, the Tutorial from Daniel helped a lot!

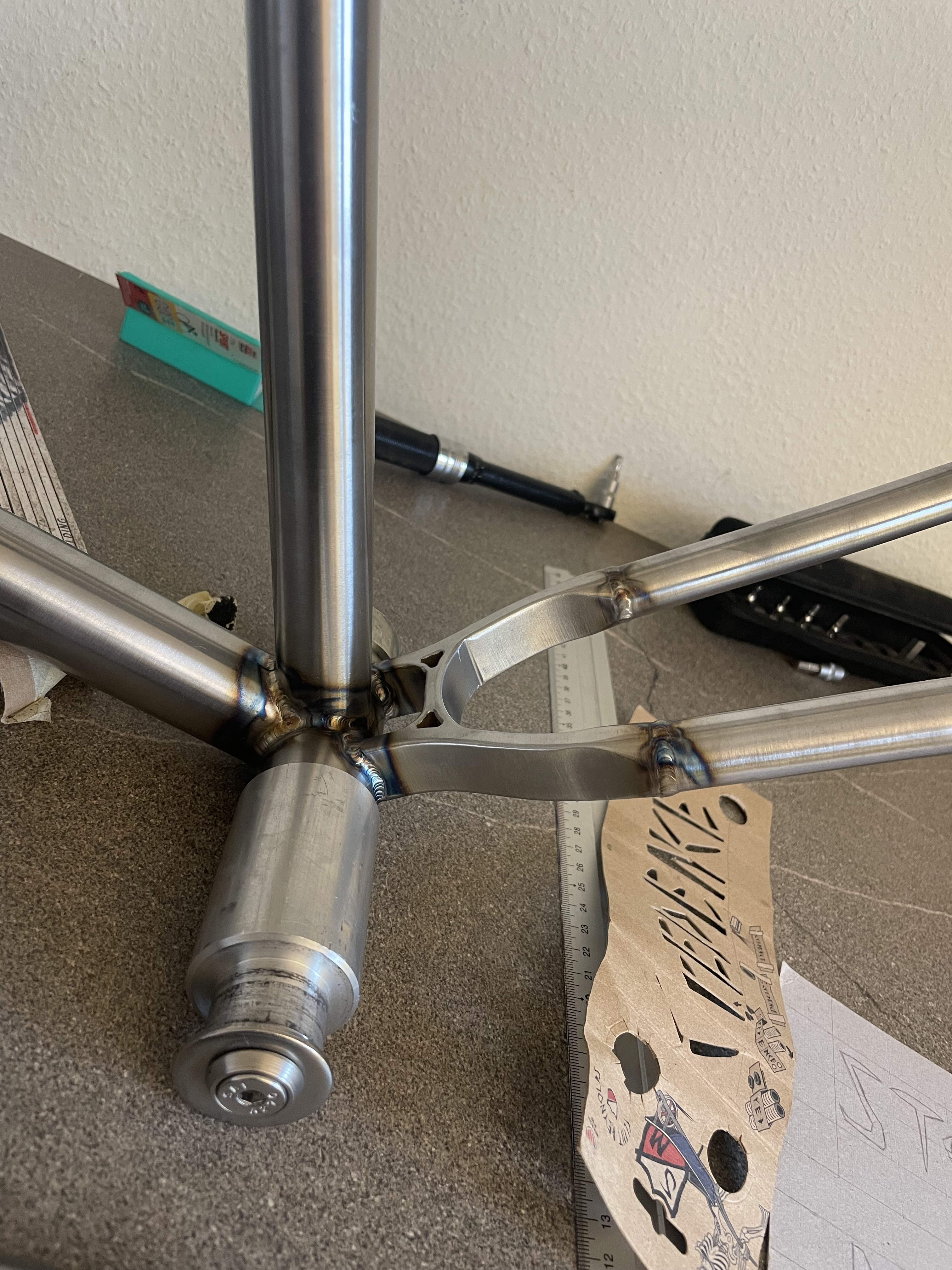

Wich also improved the look of the yoke because I could waterjet cut one. (The old one looked like bbq pliers)

The yoke allows me to barely fit a 26“ wheel, but the 24“ rides so good that I never tried a 26“

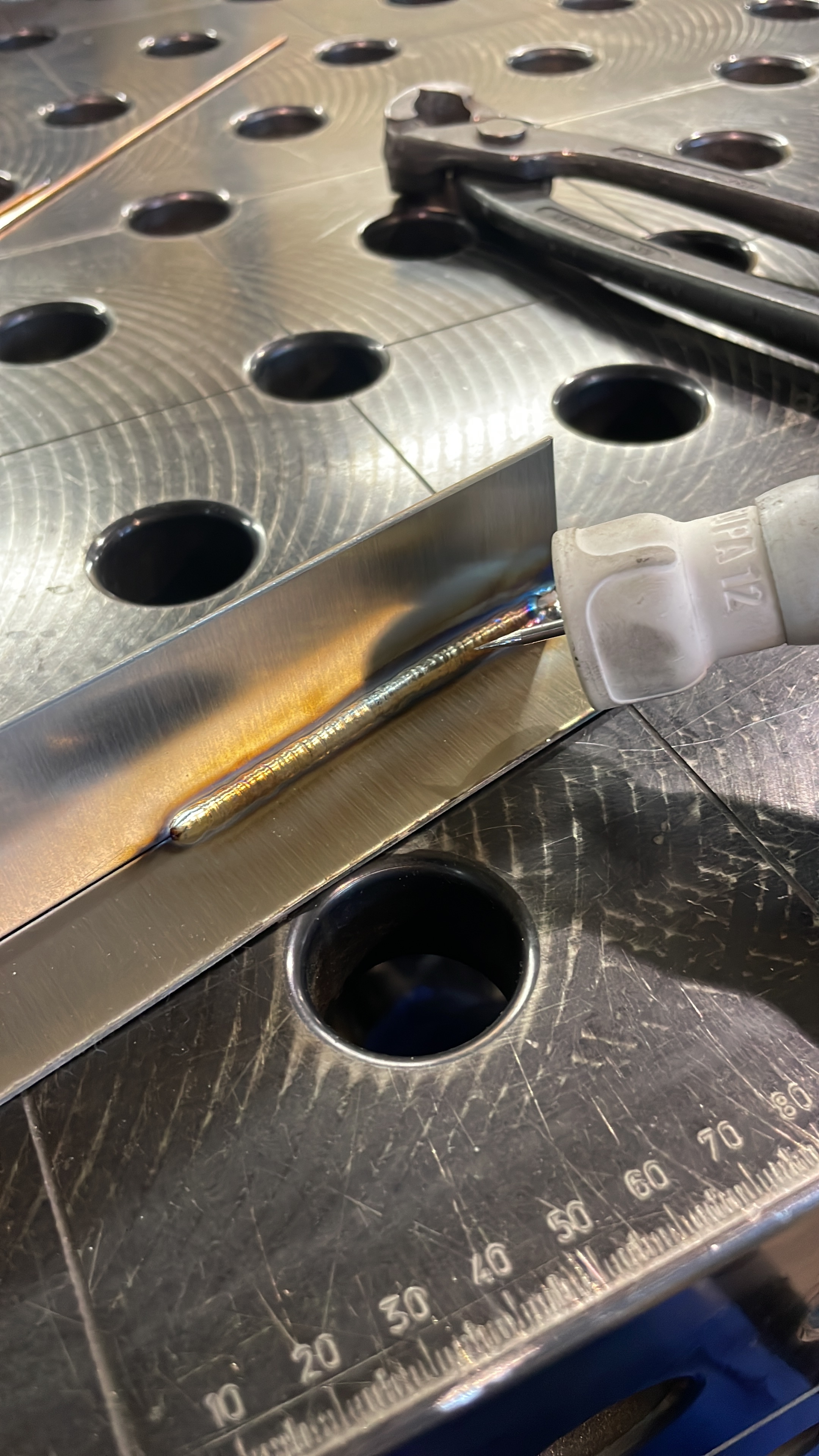

The bends of the chain and Seat stays also came out way better than on the first frame because I used a different tighter bending die.

And I actually prefered mitering the tubes by hand because my lathe set up wasn‘t that ridged.

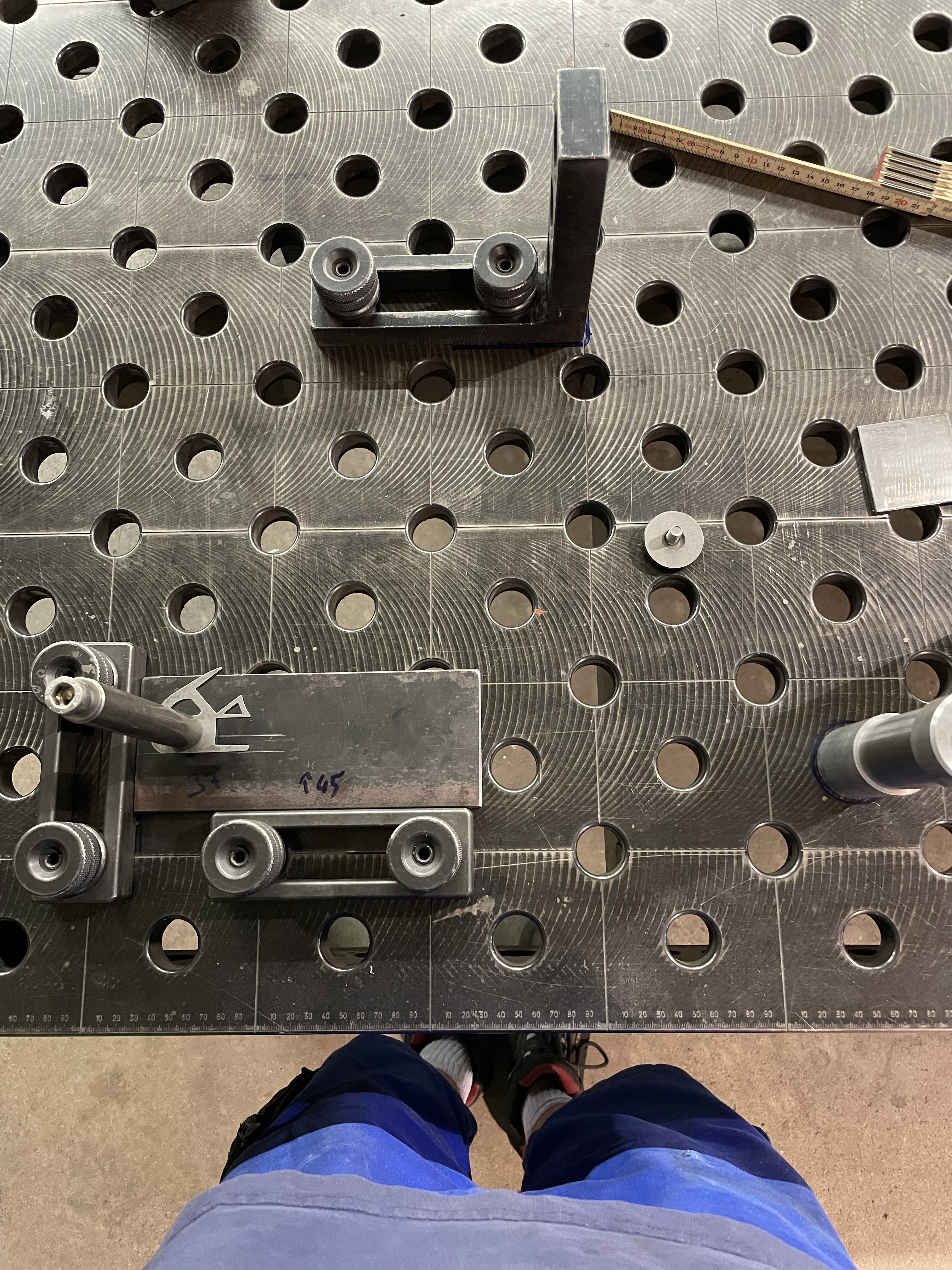

And I Improved my jig, the first one worked fine but i had to cut it apart to get the frame out.

I really like clear powder coat and I didn‘t have any issues with the first frame (almost no spider webs after 2 years just some really small ones on the downside of the bb and on the cable guides wich you barelly notice)

And I have put a lot of work into the frame and it would be sad to hide all the work.

Finished Frame:

My latest project was welding a disk brake mount on a bmx and modifying a old hub to fit into the frame:

I am really lucky that my chamber of crafts pays a frame building course in Zürich by Kolb Rahmenbau.

My plan for the course is to build a fullsuspension trail bike with 135mm of Travel

I have already started to build a jig for the rear end and I can’t wait to build the bike!

Thank‘s for reading this far, I would be happy to receive any questions or feedback