I did a bit of investigation and asked our print supplier. I didn’t want to ask where people’s parts are printed, but I have a feeling most go through the supplier NMW uses.

I don’t think the parts are that porous

I find it unlikely that gas was escaping through the parts. I think the level of porosity for that to happen would be obvious.

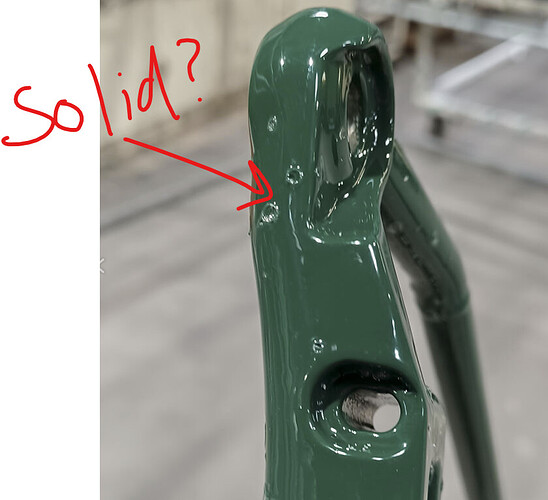

Also, the bubbles are forming in places that are solid:

Surface contamination?

I think the most likely explanation is surface contamination. It is claimed that the bubbles went away after venting, but I think it is more likely the bubbles went away after the frame was stripped (I assume chemically).

Our supplier recently had an issue where oil was getting onto the parts somewhere along the process. The contamination was obvious, and they sent us new parts without asking. Because of the surface texture contaminated parts are very hard to clean. I think bead blasting the contamination just embeds it further in the surface.

Surface Porosity?

We get a tiny bubble just like @project12 once in a while:

Printed parts are never going to be 100% solid. My theory for the random bubbles is either a tiny cavity on the surface “opens up” during heating, or the powder struggles to attach to the texture of the part.

Conclusions:

As always, I encourage people to do their own investigation and research. Just because someone printed something does not mean it’s a good idea!

The strength of a part comes from its design. it’s easy to get carried away with the ability to print complex shapes and chase weight and cost savings, but printability (the ease of printing) should be the biggest concern when designing additive parts. Just because you can does not mean you should!

A perfect example is printing zip tie guides directly onto parts:

- stress riser

- sudden change in wall thickness

- two supported overhangs.

An innocuous feature has three of the no-nos of additive. It may look perfectly fine (and it might be), but to me, it carries too much risk. Since you are brazing zip tie guides to a frame anyway, it’s not much more time to braze it onto the printed part.

Another clarification: just because a print partner is low cost, does not mean it is bad. Our print partner in Asia is much cheaper than domestic options, but they have been the most open to feedback, open to improving their process, and easy to communicate with. I have had the exact opposite experience with domestic print partners who have a know-it-all attitude.