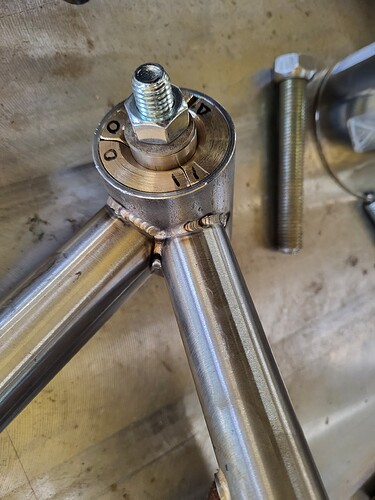

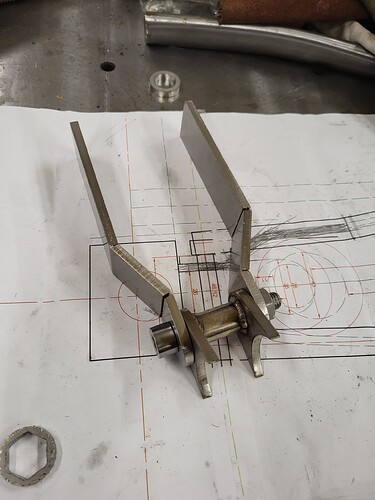

What I did manage to do right was this adapter to pair cyclus handles with park PF30 facing tool.

Hyvää päivää!!

karjalanpiirakka, salmiaki and kiitos

That is all the Finnish I have learned over the past 30 years married to a Finnish woman! I have visited many times over the years. You are doing some really cool work. We won’t be visiting this summer but perhaps next summer I can stop by and hang out for a while.

Keep posting!

Sometimes you have to do silly things to keep your love fresh. I call it the Surly Stack. Steamroller + Straggler + Pelago Hanko

You are welcome (as is any framebuilder visiting Finland) to our shop! Sauna will be warm and beer cold. Yes, of course our workshop has a sauna! ![]()

I made some more tools. This eccentric thingamagic rounds dented 34mm ID headtubes. I welded a 1/2 socket at the end for a lever.

I got a Surly Steamroller, it’s my first. Helsinki is the world’s Steamroller capital so me jumping on the train this late in life is justified. I’m planning to make this my business bike to pack it in the back of our Audi for work trips… so no fixed gear this time. I find it weird Surly hasn’t made a cantiboss version themselves, MASH and Cinelli are dominating that market. Well, anyway, I’m still pondering if I should give it the split treatment.

I also made a shower tray. Def not a bicycle related thing, but I also wanted to try and make a one. It’s all laser cut 5mm stainless.

I put some parts if the tallbike, but it seems I need to modify the lower crankset unless I run the two cranksets with identical gear ratios.

we made a video with my girlfriend. it’s for some silly bicycle build project, where you take the worst possible bike and convert it to a rando bike.

Long time no see. I’d like to discus whether life is long enought to do stupid projects for people you hardly know, when you have friends and family that need stupid projects too. Anyway.

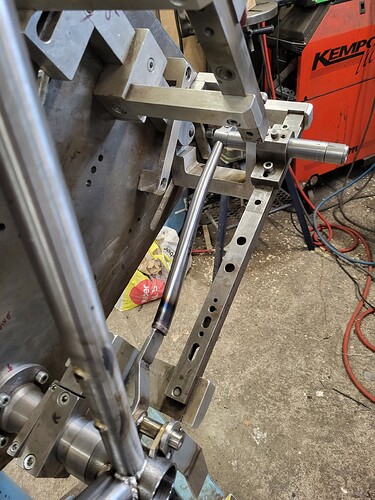

I am going to the CMWC 2023 in Yokohama and I nees a split bike to fly there without extra charges. Other specs: Thru axle, PF30 to run a WMFG excentric BB in case I need to throw in an ISO track cog for fixedgear battles, standard 1 1/8 395 a-c forks, split rear triangle.

I finally had the tenacity to make a bronze heat sink for PF30. I did not do the Paragon tango but simply split it in three sections with an angle grinder.

I wonder when I will have the tenacity to set-up my tig welder with pulse? Regardless, I am happy with how my welds turned out. Laying the frame flat on a table really helps.

Do the stupidest stuff for people you hardly know and learn a thing or two

I have a pretty tight schedule to get this rear welded up and right now it looks doable. Planning and preparation is paying off.

I have used regular steels (SSAB Raex or something similar) for my splits, but this time all the parts are stainless so it won’t rust or corrode even in winter use. The bolt is grade 5 titanium, because why not. Why won’t Paragon make Syntace drops in stainless? ![]()

I don’t a have broaching tool so this is how I make a piece to hold a nut on my split seat stay. I machine down a socket, cut the piece and silver solder it inside my stainless piece. I figured this is a safe way to go instead of threading my parts - if the bolt snaps, I can always get a M6 nut and bolt from any hardware store.

This time I was had to do it twice as I got generous with solder and it built a fillet inside the socket ![]() .

.

Hey, any thought on where to mount the rear dynamo light on a split bicycle? Ideally it should be somewhere other than the stays or the saddle as they will come off when the bike is packed.

Thanks so much for showing how to do this heat straitening technique in a video! Very cool!