Hi. Framebuilder from Helsinki, Finland reporting in. I’ve been building frames since ~2015. I’m part of a builders’ group in Helsinki called the 4130 Ranch (named after our infamous secret hideout). Going to dump some picture of my builds here and then start documenting the build projects.

Instagram

Flickr

First frame

26" fixedgear winter rambler

Daily rider

Trackbike

Brooklunker

Express Noodle

San Chinko

Failvanger

Tracklocross

Physeter Catodon

Yoshi (

Build-a-Pelago competition bike)

Christmas Klunker (built together with my shopmates)

13 Likes

A timelapse video of our “Ranch” during our traditional Christmas-Bike-Build-Off (CBBO).

7 Likes

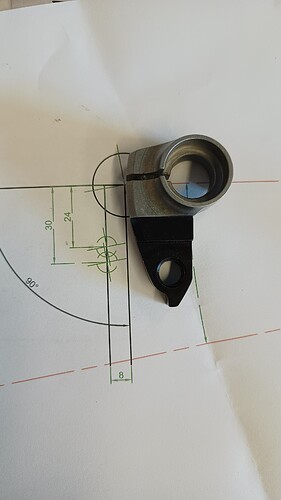

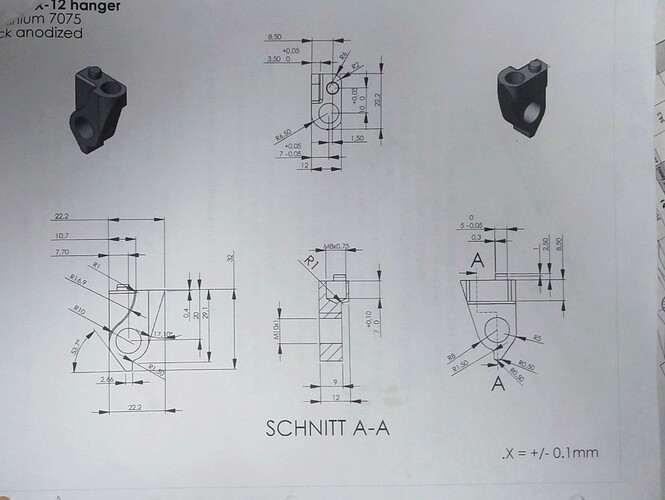

At the moment I’m trying to figure out what the standard for Syntace drop-out hanger is, it seems a few mils longer than the 34mm MTB max on SRAM frame specs.

Is it ok to use metrics on this forum? I know Amurica did not fly to moon using millimeters.

10 Likes

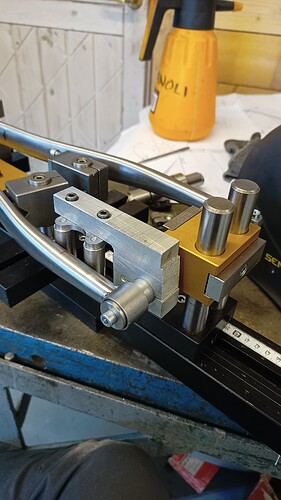

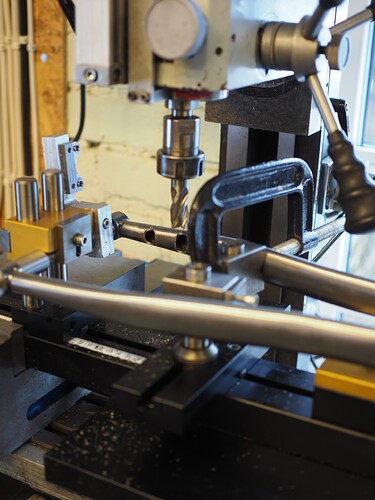

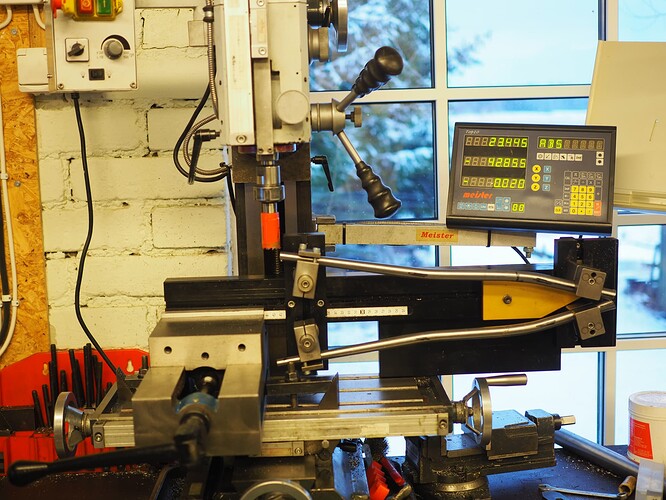

I’m using a combination of a Mr.Wolf jig, Incipi flat mount jig and some parts I’ve machined out in hurry to align flat mount brake bosses on this frame. My idea is to fixture the jig on our mill in the correct angle for the FM bosses, use the mutilated Incipi jig to align a drill bit and then swap in a 16mm hole saw to rip in the final holes.

This is my current project, it is an update on the Pelago Sibbo crossbike for a friend. Slapping on a thru-axle and flat mount brakes instead of the dependable and easy to work on QR/IS.

Pretty nerve wrecking stuff. My 16mm hole saw was more like 18.5mm hole saw, but I found a 16mm endmill.

7 Likes

Usually we ban people for mentioning the metric system, but we’ll let this one slide

Love your builds! The 4130 Ranch seems like such a unique treasure

5 Likes

That looks like a really fun shop and community. It would be awesome to start something like that in San Francisco. Do you all have a website? Is it all word of mouth?

You are right, that does look a little bit long. I don’t have CAD file for that style of the hanger. @mark_pmw might be able to chime in on monday.

Metric is only allowed for discussion components and geometry, imperial for tube diameters and mountain bike tires (sarcasm).

3 Likes

Thanks! We used to rent an insulated shipping container for a workshop, but it was pretty grim. Then Otto bought a derelict farm and we moved the shop into the old barn. It’s hard to find spaces around the capital in Finland so it is a 30 minute drive. We don’t have a website, only Instagram accounts, but we don’t really seek work or new members so it’s fine (always open for commercial partners, though!).

There’s a dozen individual builders in Finland, but I think we are the only community, if you want to call it that. To my knowledge, at the moment no one is building bikes for a living, though Konga is selling his framebuilding tools.

I went online to look at some photos and DS dropout seems to be always aligned with the mouth parallel towards the BB so I just did it like that left the maths to the smart guys.

I managed to update the first post with more pictures and links now that I am a trusted member of the community

1 Like

Here’s a print from Syntace. A print like this is extremely valuable for manufacturing, as the tolerances are here. Remember, this was designed as a mountain bike hanger, so it is a bit longer than a typical road hanger of the time. In terms of how fast bicycles have evolved in the last 10-15 years, this is an old design. Here is the .STEP file:

SY4013.STEP (110.9 KB)

(Metric dimensions are OK, if you work with bicycles long enough you become bi-dimensional.)

8 Likes

Thanks for specs!

In Finnish an inch is “tuuma”. When we need to take a minute to figure something out we say we take a “tuumaustauko”, literally an inching break. So yes, our language has a term for the moment it takes to calculate how many inches a metric measurement is.

In other news: My on-going passion is building split bikes for cheaper travel by train or plane. My Yoshi-bike is the latest. The split has an M10 bolt behind the BB and an M6 at the top of the seatstays.

With the flat-packing rear triangle you can just squeeze the bike in the regular luggage size. With 650b wheels it’s even possible with gears and disc brakes. These are not folding bikes, the idea is more to unpack it at the airport or train station and spend a crazy week in town riding a real adult bicycle. Disc brakes don’t really go well with packing and freight, but I am a bit hesitant to go as small as 26" and 650b disc brake rims are quite valuable.

^ I used the front triangle of a Pelago Stavanger to build this Failvanger for our trip to Osaka. Guys from Movement Bicycle Studio inspecting the bike in the picture. I like the light carbon fork, but it is a PITA considering front racks, which I love for hauling around my luggage.

7 Likes

Cheers for posting your nice bikes.

Super envious of that community shop space!

When I moved to my current spot I searched high a low for something similar…

I found nothing in the end (there was one expensive shared workshop setup, but was targeted towards business startups) and it just took a long time to setup something workable.

2 Likes

Having more people helps with getting the more expensive equipment. We also do a frame raffle at Christmas and it usually yields enough to get a used jig or something similar crazy expensive.

5 Likes

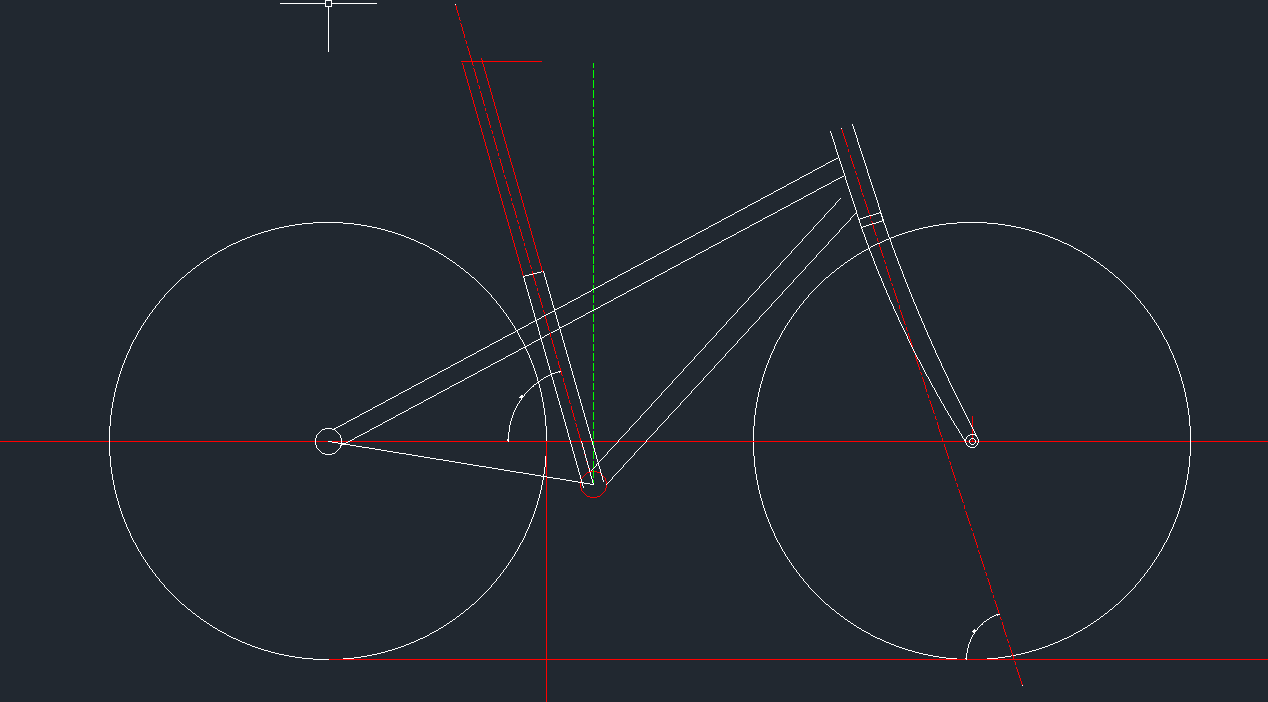

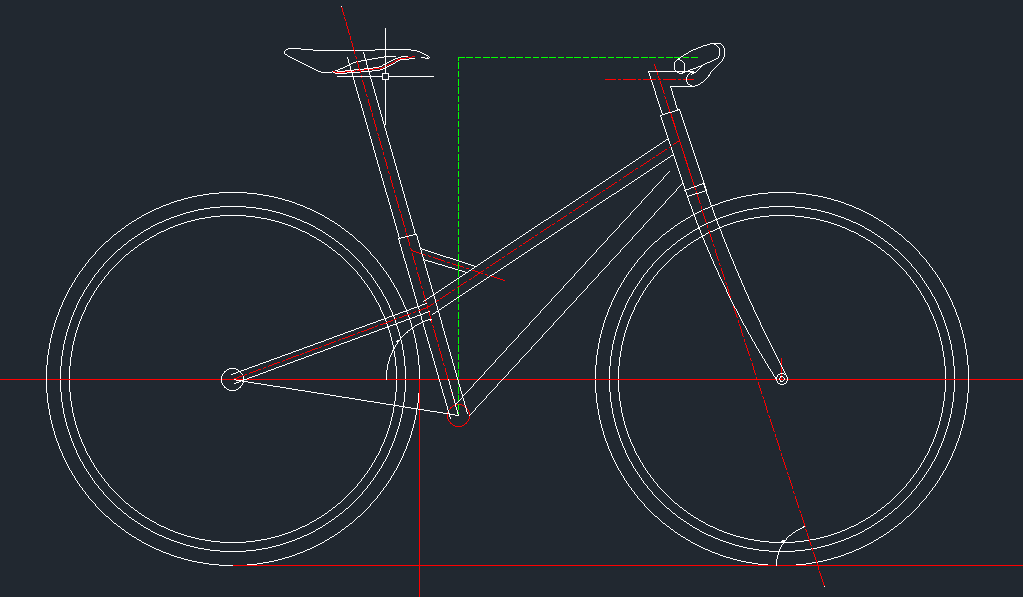

How do you feel about a road bike with an extremely short seat tube? My fiance has a hip problem and cannot get her leg over a high top tube. She rides a vintage French road frame with a tall quill stem and flat bars in the summer and would like to have this sort of “light” ride, that’s easier to mount. I was looking at how mountain bikes have silly low frames and almost horizontal seat stays - this must be possible for a road type frame as well?

2 Likes

10 hour day at the Ranch

I may not have thought the chainstay placement through with the care it deserved. The breather holes are partly through the thread, which will make an internal cable routing conversion demanding in the future… like that will ever happen, but at the same time I’m thinking this kind of nice frame deserves having the cables hidden.

I welded the brake mounts mostly while still on the rear jig, partly with only the axle and jig fastened to the stay and a small seam while on the frame jig. Welding two separate mounts to the CS is such a silly thing to do! Twice the amount of things to twist with heat.

I hid two fender mounts on the inside faces of the STs so that the bike won’t look too practical. Still have to fabricate the bridges with fender mounts, but before that I’ll take the frame somewhere, where there is an actual 622 thru-axle wheel so that I can see how it fits.

4 Likes

Why not just build up a mixte/stepthrough style frame? The short ST on a MTB allows standover clearance and a long dropper. Without the need for a dropper on a roadish bike you could be better off with the steeper stay. The design you have there might look like a bit of a freak bike (not always a bad thing) where as a stepthrough is totally classic look.

Most probably ZON114OV425133CR.

Sounds like a plan!

4 Likes

Soooo. These are frame jigs that I use. They are both old production jigs from the Finnish bicycle manufacturer Tunturi. When their Finnish factory was closed, they were selling off the equipment, but the jigs were superrrr expensive and hobbyists couldn’t afford them. Then some months later the factory called these hobbyists and basically told them they could get them for free or they will be thrown in the recycling bin. I think there were three jigs in total.

I bought the top one from of the hobbyists for some very reasonable price. It is serial production jig - time consuming to set up but has a dozen little clamps and jigs to position all the parts accurately. In the picture I’ve been setting up the head tube position using a ruler.

The second jig is also from Tunturi, but unlike the first (which sees completely custom) this one is still in production somewhere in Italy. New one costs something in the vicinity of 10.000€, we paid a couple hundred for ours. Everything is steel and there are even some rulers to set up the geometry - not 100% accurate, but helpful.

I’ve also used a steel plate and even an old MDF table top in conjunction with a BB post to build frames. My father has a wood workshop and I just cust some wood blocks to correct length to space everything on the table and drawing.

4 Likes

Your fixtures are really interesting. It’s cool to see true production fixtures. Do you have any idea when they were made? Are they indexed, or do you need to measure the fixture externally? It also looks like the seat tube angle is fixed. Do you adjust the angles relative to that seat tube angle?

1 Like

In the top one the ST angle is not really supposed to be changed, but there seem to be holes for two other positions as well. Changing the rear axle position is easy and HT location adjustment usually takes fiddling with bolts. Once it’s dialed in, you can easily knock out a hundred identical 90s MTBs.

In the lower one pretty much everything is adjustable. There are big levers on the backside to release and lock the ST angle, the HT position horizontally and the HT angle. I haven’t quite figured out how the head tube is located vertically using the jig’s dials, but the jig has an inbuilt “fork” with rake adjustment. I think the idea is you can set up a geometry (including wheelbase) on the jig without making drawings of the frame first. The NJS builder Nagasawa had made a similar tool for himself as well, a sort of a mechanical design aid.

Don’t ask me how it works!

4 Likes

Well that didn’t go as planned. Something is off with our jig or the thru axle dummy. The frame came out with one CS a millimeter too short. Didn’t help that I didn’t have a complete wheel to check the frame so only found out after welding everything up. Live and learn.

4 Likes