We’ve veen Turin, Italy now for a couple of days. Managed to ship the bikes here relatively unscathed. Nina is still happy with her new bike. The fender I made her is about an inch too short and some dirt ends up on her Kånken backbag, I would still call it a success.

I really love the blue bike. Do you have a name for it? The double-diamond frame is so common that you rarely see anything novel. Even when you add a curve tube here and there, they all look the same. The blue bike breaks all the rules and looks great doing it.

Thanks for the kind words. My fiancé is calling it the Rheumatic Rocket ![]() (reason, she has a bad hip).

(reason, she has a bad hip).

I made a split conversion for a friend, who’d like to travel on the bus with his steamroller. I have to start thinking about the quick release split soon because these bolt splits are getting too easy and not stressful at all.

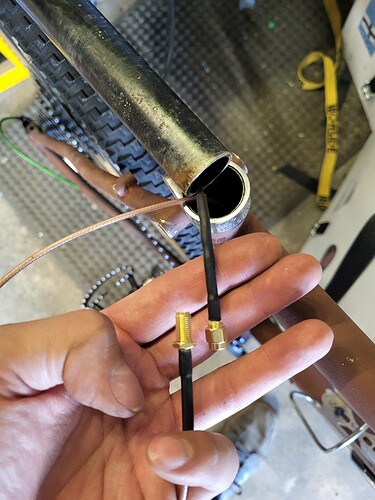

I’ve been searching for a better dynamo light connector and now I’m testing these coaxial SMA connectors. They look smart, don’t come undone by themselves (unlike SON coaxial) and cost about 2 bucks a piece.

Those look pretty nice!

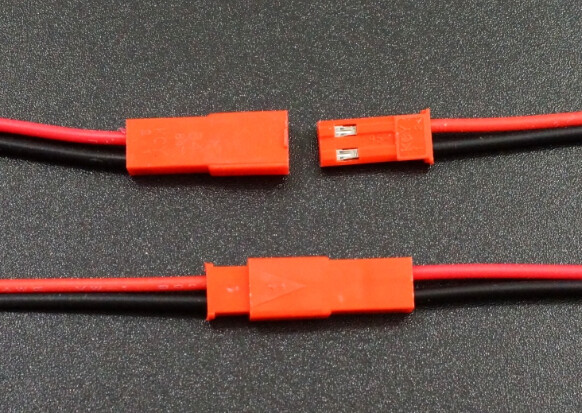

There’s also JST RCY type connectors that are pretty easy to work with and very vibration resistant. Very slim, inexpensive, and you can get them pre-wired so you don’t need the tools to do the crimping, which is the expensive part.

I pack them with a little electrical grease when they may be in a slightly corrosive environment. Sometimes I heat shrink each side for better grip as well when disconnecting.

Christmas holidays are on and I have more time to work on frames. This one frame has been a pain in mu butt for eight years. A friend sent me a box of tubes he had ordered before coming to the conclusion he was not going to build a frame himself. Most of the tubes were at least a size too short for a bike his size. We made a deal I would order new tubes and use his tubes myself. I moved and then I could not find a fork crown for the tires he wanted etc. Then finally maybe a year ago I though I got the frame and for down. “Build a rack for it. Can you paint it?” he replied. I lost my motivation for a year again ![]()

I’m sure I can tip my motivation towards finishing this once I have the basecoat on it.

Since I didn’t get any stipulations on paint, I used leftover Montana spray paints and clearcoated them with 2k acrylic. I’ve cut templates for decals in vinyl and once I’ve painted them on, I’ll do a final clear coat.

@normaali Can you get me the names of these builders? I’m mapping European Framebuilders for my PhD research project on framebuilding…

fascinating thread - im interested in the bag you use there? there is a lot of info on using soft bags for travel as an advantage over hard cases such as s&s - is that a custom bag? (vested interest as im about to take delivery of a multi- coupled bike!)

Yes, it is custom bag made by my friend Olli. It has a light inner lining under which you can slip a piece of cardboard to make the bag semi rigid. There are also Ortlieb pannier clips to the carry the folded bag. It’s a handy system as you can bin cardboard and padding at the airport and find some new ones when flying home. Easier than trying to source a complete bicycle cardboard box at the destination and you can also use the bag for rinko on trains.

If I was arriving and departing at the same place, I might use my ridig box and leave it at the airport.

Our philosophy is to dream up a bicycle trip with impossible obstacles to overcome and then engineer around them by building a custom bike and bags ![]()

amazing! thank you for the info - i am, planning to sew my own bag for mine - trying to shoe horn a ',modern geometry rigid mtb ’ into a flight sized case - has led to some interesting decisions (2 sets of couplers - fc is 800mm - offsaet rear triangle as sandwiching 2 rims and a rear triangle to get under 10" width isnt easy but wil use boost chainline).

i was going to use either cardboard or maybe coroplast to gain rigidity where needed. only if you happen to be around the bag and can take any pictures id be very grateful - and thanks for the inspiration!

maybe you can see something from this video where the camera is not pointing in the right direction. I recommend making soft bags roll-tops like this one. It allows for a lot of adjustment for different use scenario.

amazing! thank you so much that’s super helpful!

My gf has been lately talking about doing some bicycle touring around France or Italy. She is a pretty slow rider and my neck always is sore after hours of looking over my shoulder to see if she is still following. So, instead of installing a mirror on my bike, I decided a tandem is the key to success. I remember reading on an online forum that no point buying a new tandem as used ones are always available due to the romantic fantasies that husbands have about riding a tandem with their wife. So I sourced a used one for 250 finnish dorrars ($256).

All the parts are original and especially the drivetrain is junk.

So naturally I swapped everything but the drivetrain (partsbin). We rode the bike to work in the morning and seems like we might be able to ride on the same bike. Due to only the front shifter working we had just two pretty long gears, which lead to some Strava records being broken on our morning ride.

Now you are thinking, wtf man, this is custom frame forum, not a junk tandem forum. Well, my plan is to customize the frame. I’ll swap the HT to accomodate a 1 1/8 fork with disc brakes, install a disc tab in the rear and I’ll split the frame behind the front and rear seats to make this flight compatible. Just a quick update to bring this bike to the 2020s. If we are still happy after touring Italy on our Bianchi, maybe I’ll build a complete custom frame.

What tubing do you use for steel tandems anyway? Straight gauge or butted?

I drilled out the headtube on the tandem and welded in a piece of 34mm ID cromoly. I still have plans to make the tandem split, but for now I just want a bike that is rideable and has disc brakes - so I added a disc tab in the rear triangle as well.

The frame alone weights 6.4 kg ![]()

I had some Hope disc brakes with a long hose from a Bullitt and I paired them with a 180 mm disc. Putting this same setup on the fork will prob make it possible to dynamically shorten the rake ![]()

I did an axle switcharoo on a rear hub to be to use some tracknuts to keep the rear wheel in place. The future rear triangle will have vertical drops, but for now, I don’t want the hub jumping out every time we stand on the pedals.

I built the new wheels with Ryde Andra 10 rims. They weigh over 800 grams a piece and I have no doubt they will outlast everything else on this bike. I had a lot of trouble getting them vertically trued because the rims resists all attempts to corret it’s (out of factory) wobble.

We rode the bike succesfully some 20 miles and didn’t die or strangle each other. I’d like to install a camera to capture my girlfriend’s remarks about by riding style. I think this concept is now proven to work for us and I will move forward with splitting the frame plus building a new rear triangle and some racks.

My girlfriend doesn’t even let me have the controls when riding a tandem bike… Lucky man

Great 1 1/8 and disc brake conversion! I’m interested to see how you’re going to split that thing.

I modified an old Finnish (Italian made) road frame with canti studs for riding to work with dignity ja pride. I had to make a custom stem with a canti hanger for it. I had salvaged a bolt and a wedge from an old stem (from our tandem) for it and the wedge threads pulled out when I fastened it on the bike ![]() . Would not have wanted that to happen while riding. The frame has some odd 26.4~26.8 seat post size and the tube was somewhat ovalized so I just bored it out to 27.2 mm. Might fail but at least it won’t slip

. Would not have wanted that to happen while riding. The frame has some odd 26.4~26.8 seat post size and the tube was somewhat ovalized so I just bored it out to 27.2 mm. Might fail but at least it won’t slip ![]() .

.

In other news, I am making another split conversion for an international playboy friend. This one has Paragon rockers for maximum amount of moving parts.

What a blast today putting together this split conversion and when I finally have all the parts in place I take it out of the jig to check the tire clearance… ONLY TO LEARN THE ME OF THE PAST HAS USED A 120MM DUMMY ON THE JIG.

So happy I did not weld around the tubes yet.

I’m making all the split parts from stainless again. Plenty of scrap tubes around to play with.